Extracting tower for liquid-liquid heterogeneous separation

An extraction tower and heterogeneous technology, applied in the field of extraction towers, can solve the problem of not realizing that the light phase and the heavy phase are both dispersed and continuous phases, so as to reduce equipment investment and civil construction costs, reduce tower height, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

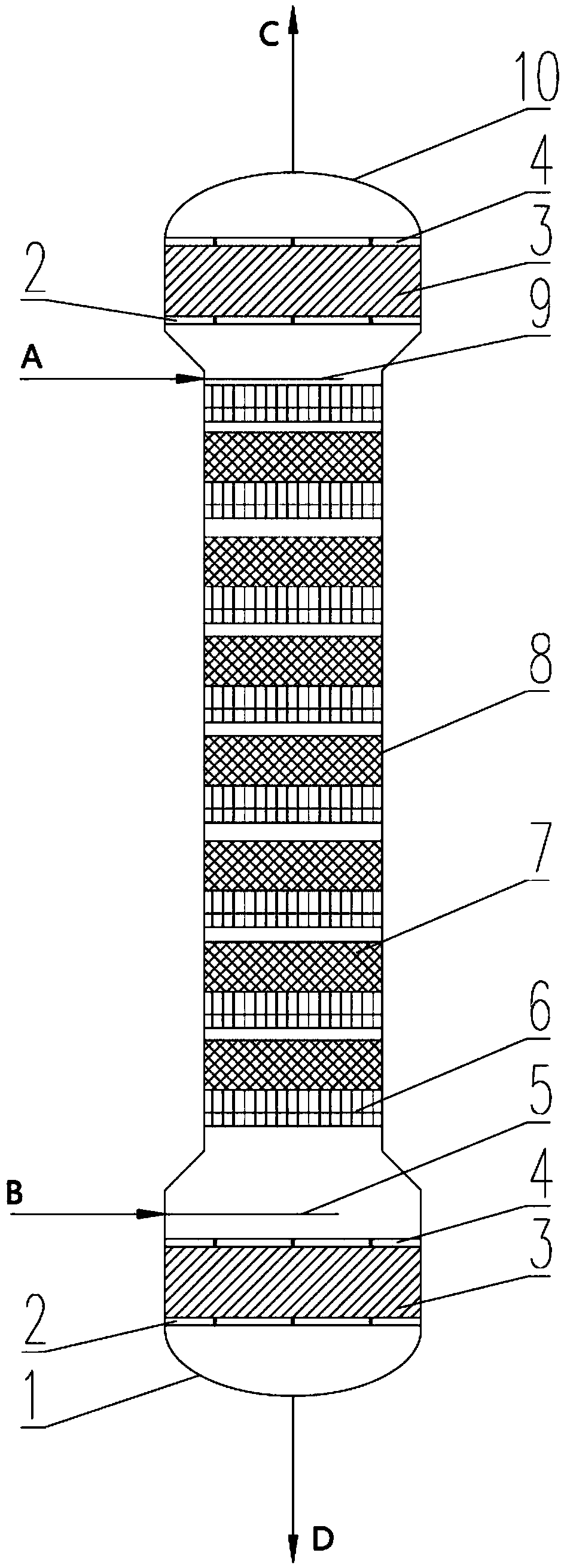

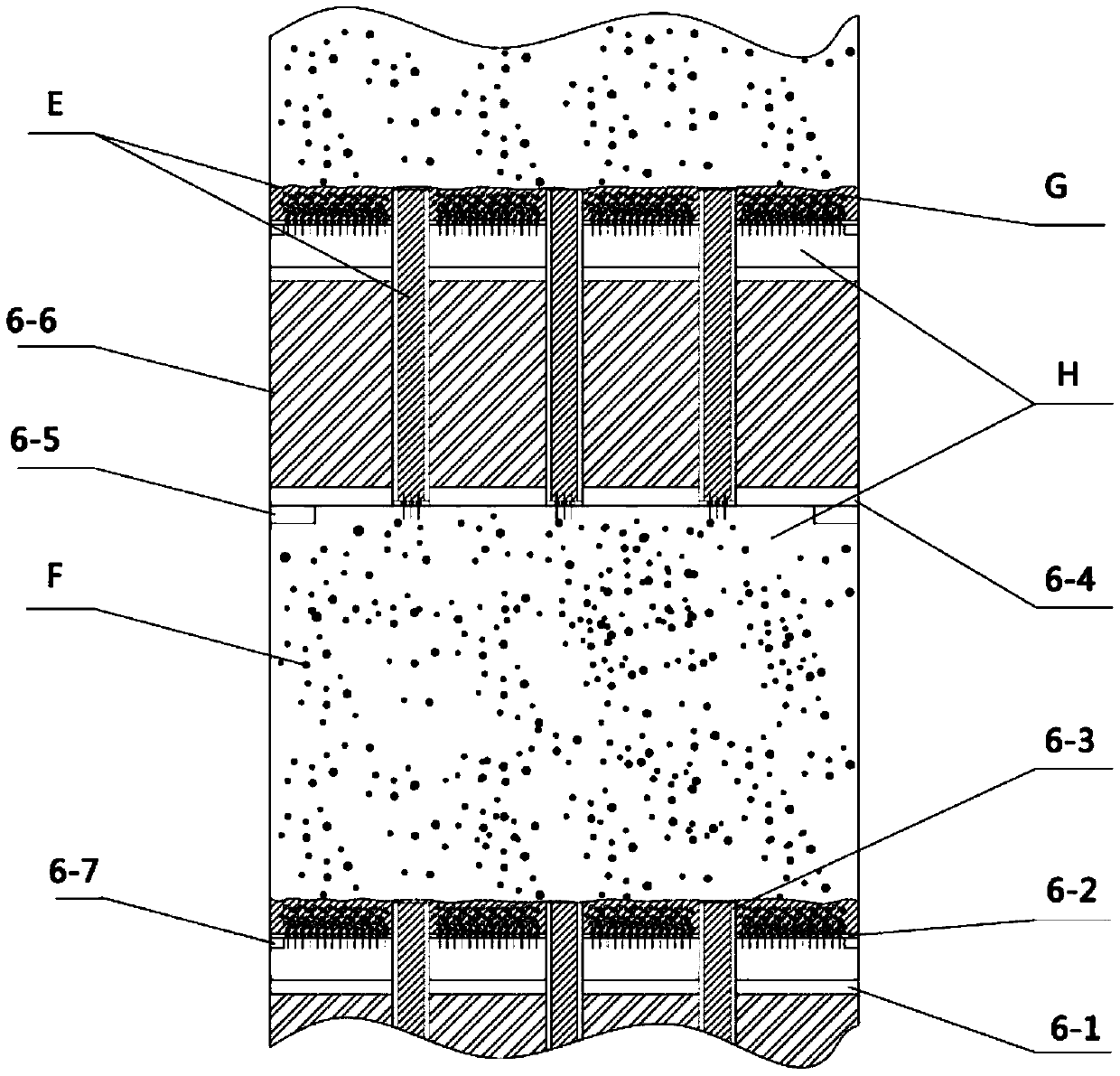

[0025] An extraction tower for liquid-liquid heterogeneous phase separation, comprising a separation chamber 1 at the bottom of the extraction tower, a separation chamber 10 at the top of the extraction tower, a tower body 8, a heavy phase feed distributor 9, and a light phase feed distributor 5 , the separation chamber 1 at the bottom of the extraction tower is connected to the bottom of the tower body 8, the separation chamber 10 at the top of the extraction tower is connected to the top of the tower body 8, the heavy phase feed distributor 9 is installed on the top of the tower body 8, and the light phase feed distributor 5 is installed at the bottom of tower body 8, and extraction tray 6 is distributed in tower body 8, and extraction tray 6 includes connecting rib plate 6-4, upper distribution plate 6-2, downcomer structure 6-3, connecting rib plate 6- 4 Installed on the support 6-5 inside the tower body 8, the upper distribution plate 6-2 is installed above the connecting ...

Embodiment 2

[0029]An extraction tower for liquid-liquid heterogeneous phase separation, comprising a separation chamber 1 at the bottom of the extraction tower, a separation chamber 10 at the top of the extraction tower, a tower body 8, a heavy phase feed distributor 9, and a light phase feed distributor 5 , the separation chamber 1 at the bottom of the extraction tower is connected to the bottom of the tower body 8, the separation chamber 10 at the top of the extraction tower is connected to the top of the tower body 8, the heavy phase feed distributor 9 is installed on the top of the tower body 8, and the light phase feed distributor 5 is installed at the bottom of tower body 8, and extraction tray 6 is distributed in tower body 8, and extraction tray 6 includes connecting rib plate 6-4, upper distribution plate 6-2, downcomer structure 6-3, connecting rib plate 6- 4 Installed on the support 6-5 inside the tower body 8, the upper distribution plate 6-2 is installed above the connecting r...

Embodiment 3

[0033] An extraction tower for liquid-liquid heterogeneous phase separation, comprising a separation chamber 1 at the bottom of the extraction tower, a separation chamber 10 at the top of the extraction tower, a tower body 8, a heavy phase feed distributor 9, and a light phase feed distributor 5 , the separation chamber 1 at the bottom of the extraction tower is connected to the bottom of the tower body 8, the separation chamber 10 at the top of the extraction tower is connected to the top of the tower body 8, the heavy phase feed distributor 9 is installed on the top of the tower body 8, and the light phase feed distributor 5 is installed at the bottom of tower body 8, and extraction tray 6 is distributed in tower body 8, and extraction tray 6 includes connecting rib plate 6-4, upper distribution plate 6-2, downcomer structure 6-3, connecting rib plate 6- 4 Installed on the support 6-5 inside the tower body 8, the upper distribution plate 6-2 is installed above the connecting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com