Four-piece type imaging lens group

An imaging lens, four-piece technology, used in optical components, optics, instruments, etc., can solve the problem of not being able to further meet the requirements of thin, wide-angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

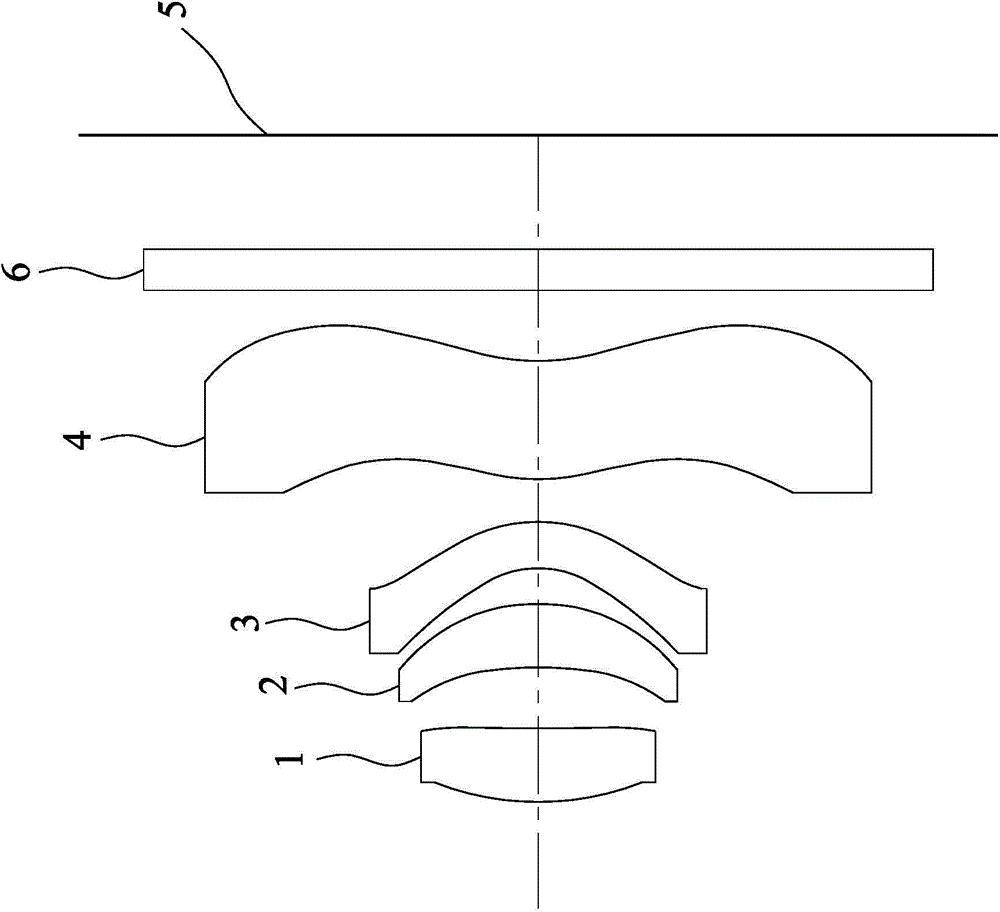

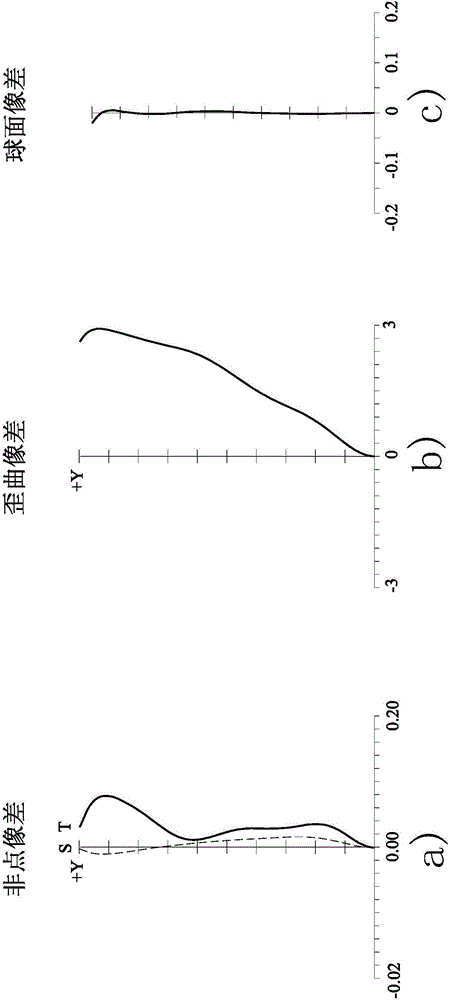

[0077] refer to Figure 1 to Figure 4 , a specific embodiment of the four-piece imaging lens group of the present invention includes sequentially from the object side to the image side:

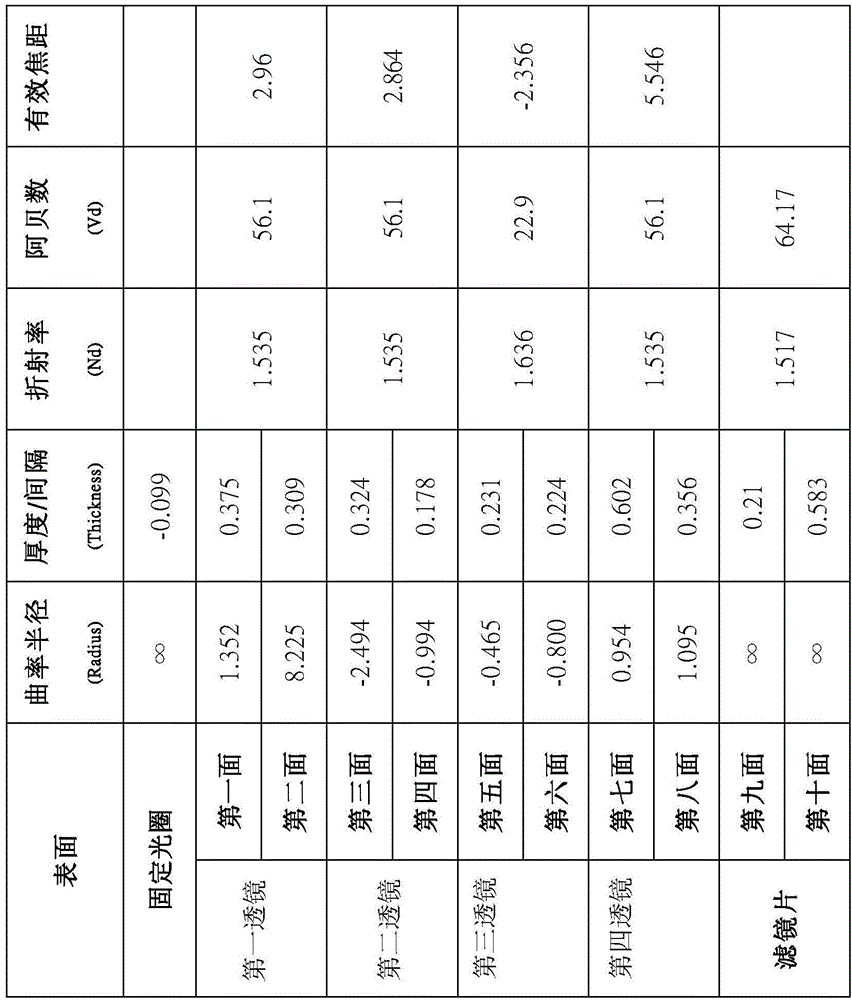

[0078] A first lens 1 has positive refractive power near the optical axis, and has a first surface and a second surface.

[0079] A second lens 2 has refractive power and has a third surface and a fourth surface.

[0080] A third lens 3 has refractive power and has a fifth surface and a sixth surface.

[0081] A fourth lens 4 has refractive power and has a seventh surface and an eighth surface. The object-side surface of the fourth lens 4 has at least one inflection point.

[0082] Wherein, at least one of the second lens 2 to the fourth lens 4 has a positive refractive power. In this preferred embodiment, the second lens 2 has a positive refractive power, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com