A kind of reaction support structure

A technology of reaction force support and frame structure, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of difficult to meet the test conditions of the actuator and no lifting function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to specific embodiments and accompanying drawings.

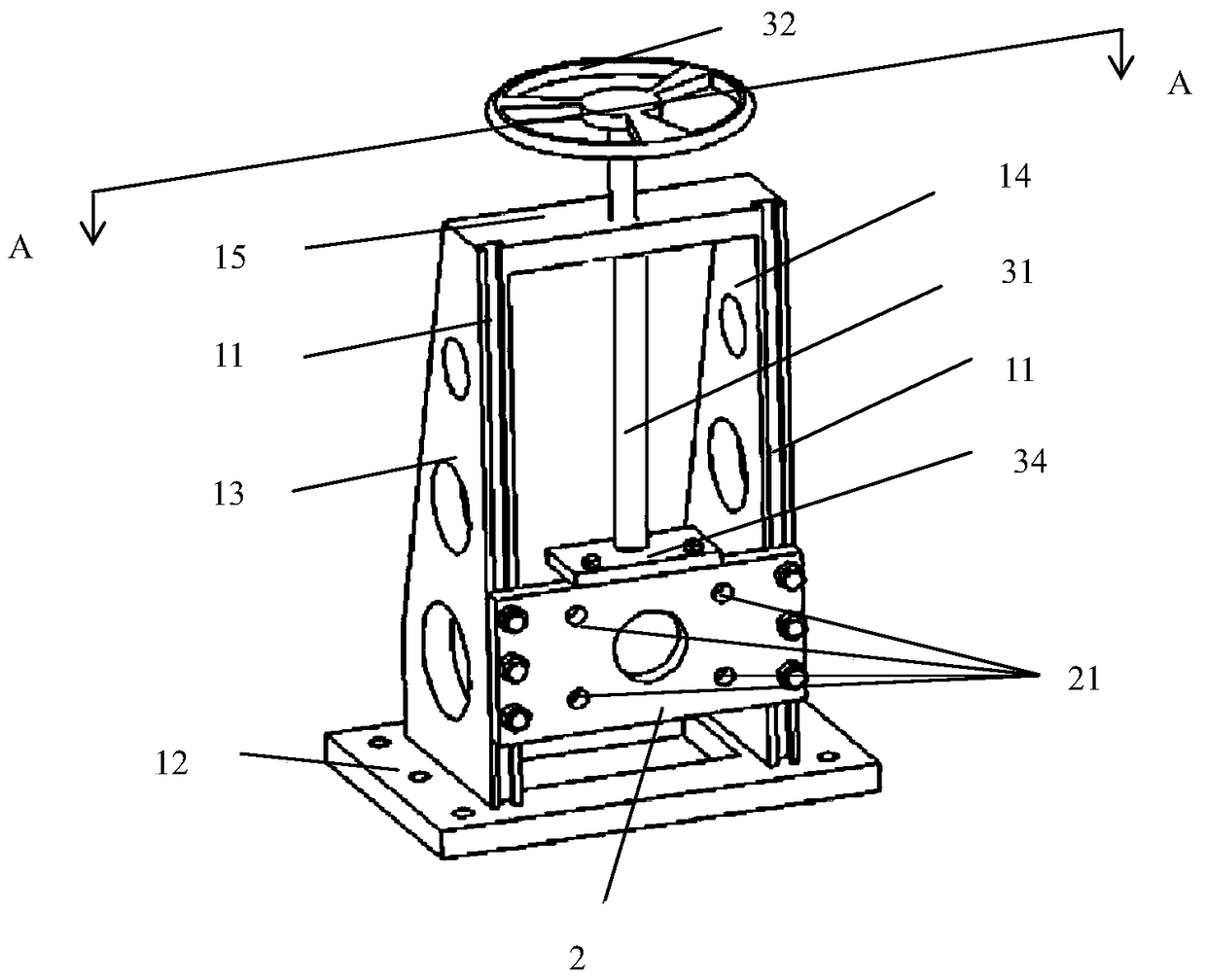

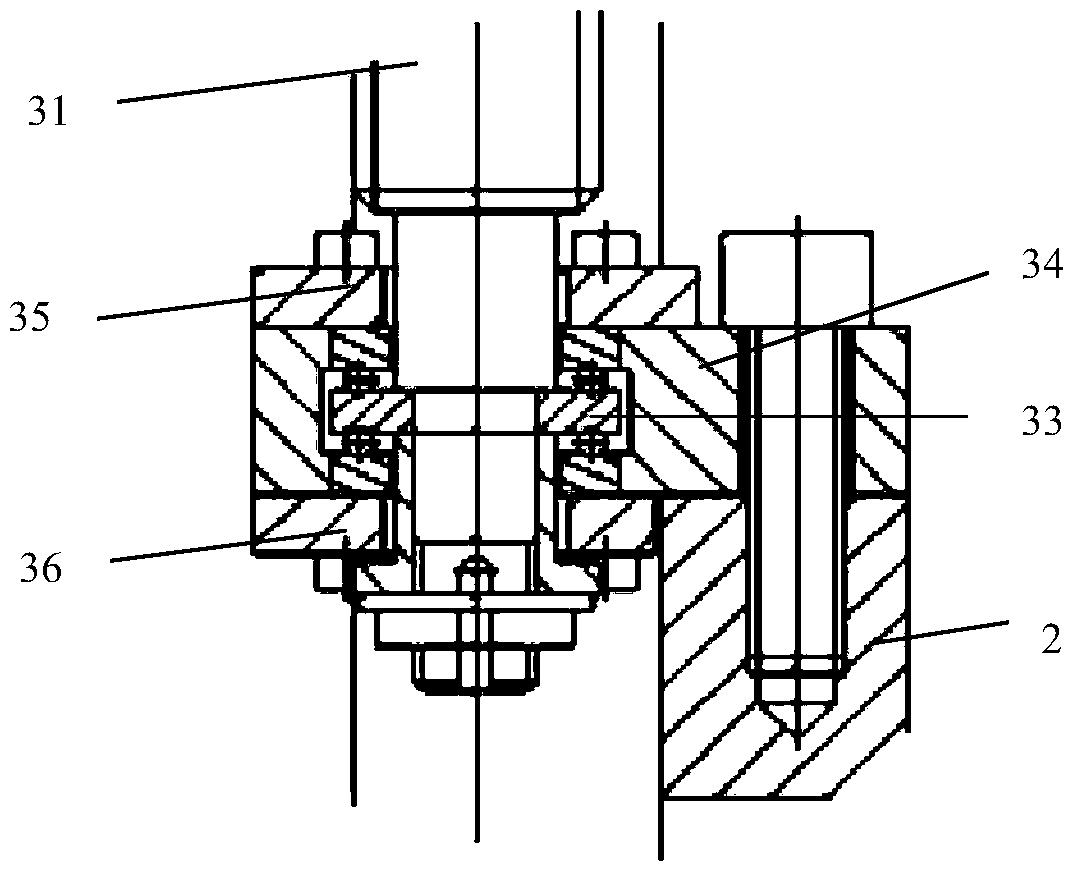

[0035] In the embodiment of the present invention, the existing actuator reaction force support structure does not have a lifting function, and it is difficult to meet the test conditions of different angles of the actuator. Embodiments of the present invention provide a counterforce support structure, such as figure 1 and figure 2 As shown, it includes: a frame structure, a connecting plate and a lifting drive structure, wherein the frame structure is provided with a chute 11; the connecting plate 2 is fixedly connected with the actuator, and the connecting plate 2 is connected to the chute through the chute. The connection of the frame structure includes a first state of being fixed relative to the frame and a second state of moving relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com