Installation locking device used for circuit board and with vibration reducing and speed adjusting functions

A technology for locking devices and circuit boards, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of increasing circuit board production costs, inconvenient centralized storage and transportation, and additional space costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

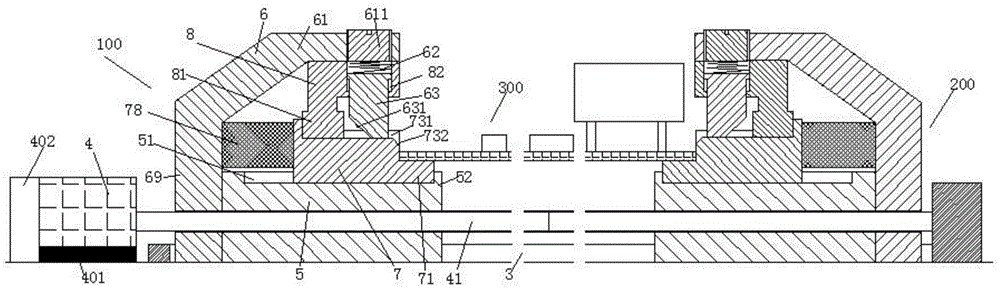

[0009] Combine below figure 1 The present invention will be described in detail.

[0010] According to an embodiment, a mounting and locking device for a circuit board 300 with functions of vibration reduction and adjustable speed includes a drive motor 4 fixedly connected to the base frame, a drive screw 41 dynamically coupled with the drive motor 4, and The two screw threads with opposite directions on the driving screw 41 respectively drive the left mounting assembly 100 and the right mounting assembly 200 , and are fixedly connected with the base frame and guide the left mounting assembly 100 and the right mounting assembly 200 The guide rail member 3, wherein, the left mounting assembly 100 and the right mounting assembly 200 are symmetrically arranged, and each includes: a threaded base 5 threaded with the driving screw 41, and an outer end of the threaded base 5 The fixed frame 6 fixedly connected, the mounting bearing block 7 slidable in the guide rail groove 51 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com