Fry culture water diversion room

A fish fry and water separation tank technology, which is applied in the field of agricultural breeding, can solve the problems of new fish fry breeding, infection, loss, etc., and achieve the effects of avoiding cross-infection of water sources, ensuring independence, and convenient switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

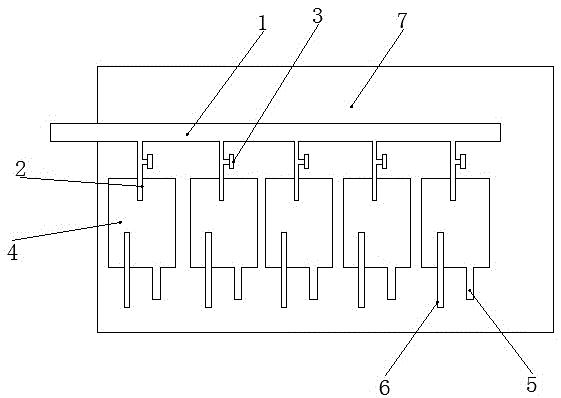

[0013] Embodiment 1: as figure 1 As shown, the fish fry breeding water distribution room includes a water distribution room body 7, and the water distribution room body 7 is provided with a water inlet pipe 1, and the water inlet pipe 1 is provided with five water distribution pipes 2, and five water distribution pipes 2 are provided in the present embodiment. Each water distribution pipe 2 is provided with a water distribution faucet 3, and the water distribution room body 7 is also provided with five water distribution pools 4. In this embodiment, five water distribution pools 4 are arranged, and the water distribution pools 4 are arranged in one-to-one correspondence with the water distribution pipes 2. The length, width and height of the water diversion tank 4 are 1m to 1.5m. In this embodiment, the length, width and height are set to be 1.2m. Plug, the bottom surface of the water distribution room body 7 is provided with a sludge tank flowing to the outside of the water d...

Embodiment 2

[0015] Embodiment 2: the bottom of the water separation tank 4 of the present invention is funnel-shaped, and the silt discharge pipe 5 is arranged at the bottom of the water separation tank 4. When cleaning, impurities such as silt will flow into the silt discharge pipe 5 along with the funnel-shaped slope. More quickly the water separation pool is cleaned up, and others are the same as in embodiment 1.

[0016] Compared with the existing technology, the water distribution room for fish fry breeding, through the one-to-one corresponding setting of the water distribution pipe 2, the water distribution tank 4, the drain pipe 6, and the breeding pool, ensures the independence of water supply and avoids cross-infection of water sources. Arrived the effect of a sedimentation, makes silt sink on the bottom surface, and drainpipe 6 then introduces clarified water and enters the culture pond, has further improved water quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com