Equipment management system

A technology of equipment management and equipment, applied in the direction of electrical digital data processing, instruments, hardware monitoring, etc., can solve the problems of increasing work difficulty, high economic cost, and reducing work efficiency, so as to reduce equipment accidents, improve management level, reduce The effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings.

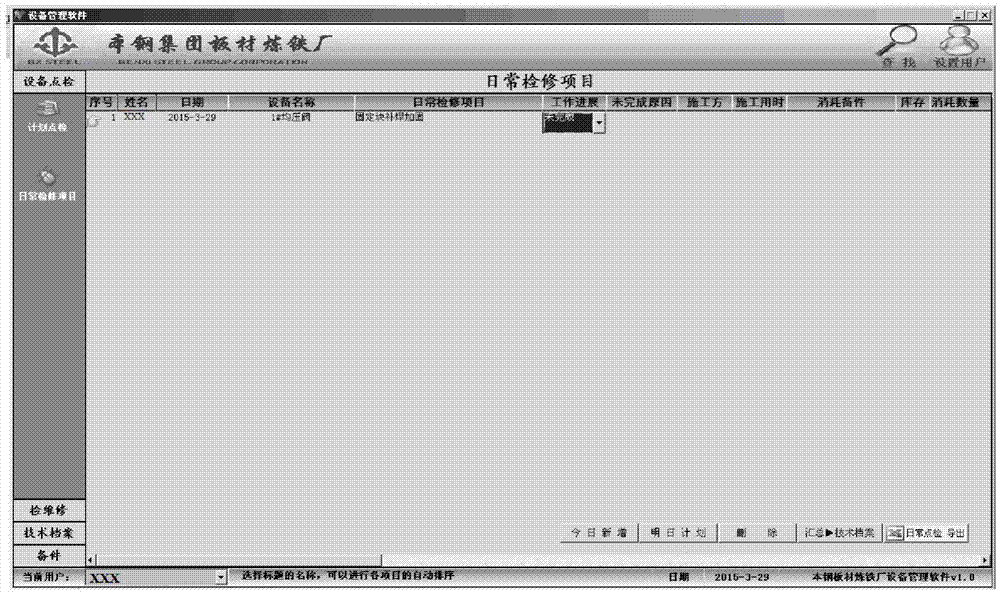

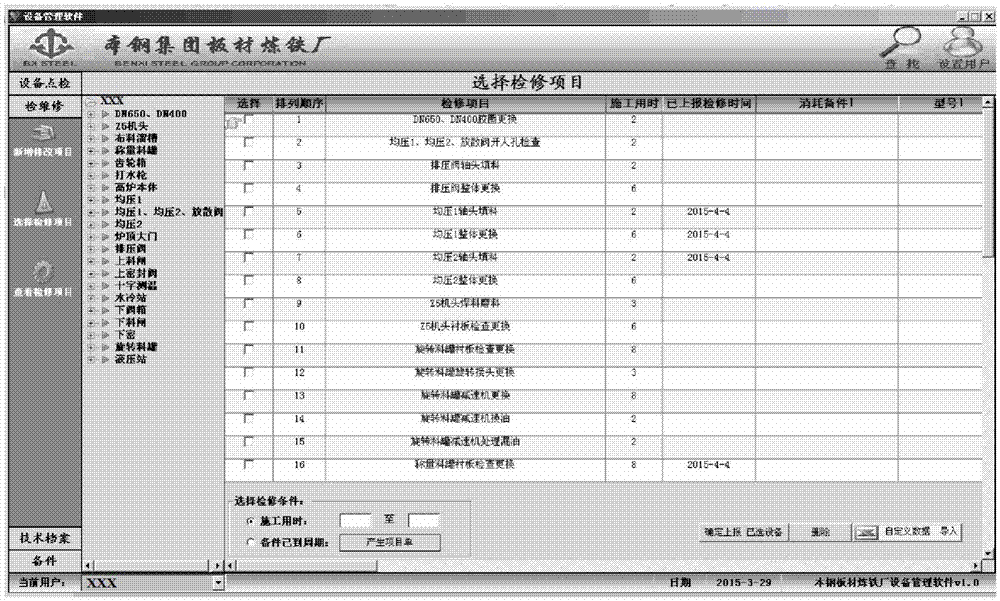

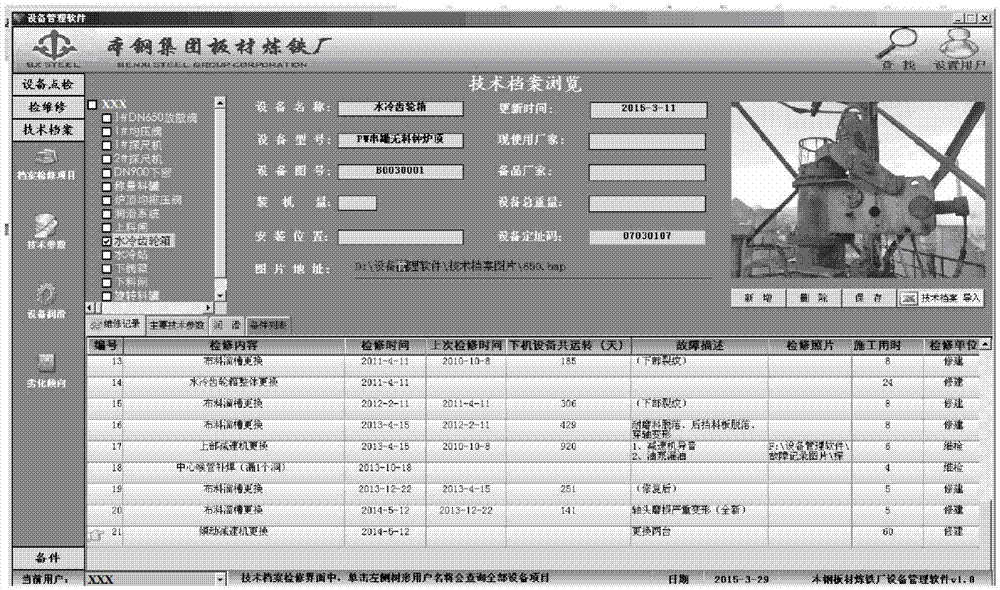

[0022] like figure 1 As shown in the figure, an equipment management system of the present invention includes an equipment spot check module, an inspection and maintenance module, a technical file module and a spare parts management module, wherein the equipment spot check module includes a planned spot check sub-module and a daily maintenance item sub-module. The sub-module automatically filters and displays the work items of the day, reminds the user of today's work priorities, and displays the item name of the fault in the sub-module of the daily maintenance item; the maintenance module is used to display all maintenance items; the technical file module displays all equipment Including equipment maintenance records, technical parameters, equipment lubrication, equipment deterioration tendency and spare parts information; spare parts management module includes spare pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com