Motor having many drive ways and capable of preventing high-temperature damage

A transmission mode, high temperature technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of unable to provide multiple transmission supports, affecting the use of motors, single motor, etc., to achieve simple structure, improve heat dissipation speed and efficiency, The effect of speeding up the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

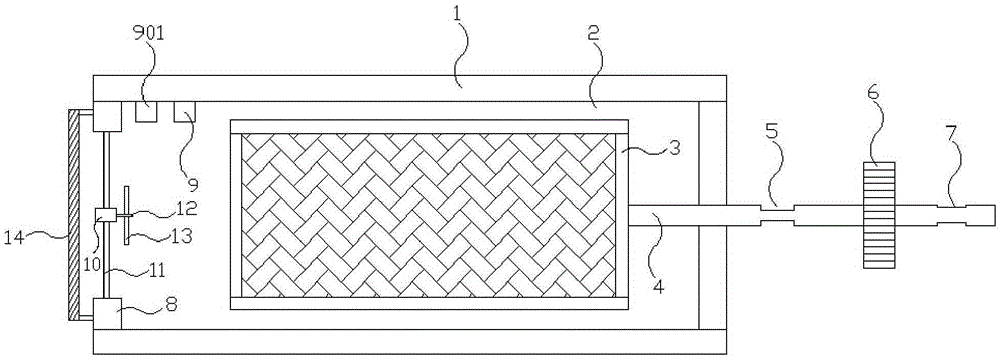

[0019] Attached below Figure 1-2 And embodiment further illustrate the present invention.

[0020] A motor with multiple transmission modes and capable of preventing high temperature damage, comprising a casing 1 and an installation chamber 2 is arranged inside the casing 1, a rotor 3 is arranged inside the installation chamber 2 and a rotating shaft 4 is arranged at one end of the rotor 3, and the side of the rotating shaft 4 A transmission groove 5 is provided on one side, and a transmission gear 6 is provided on one side of the transmission groove 5, and a mounting groove 7 is provided on one side of the transmission gear 6.

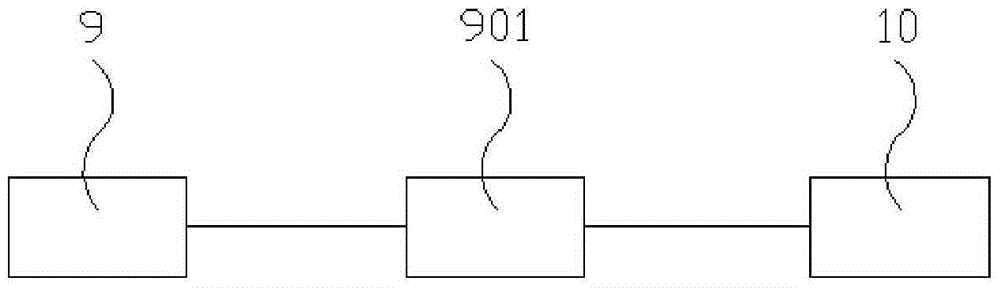

[0021] Further, one end of the housing 1 is provided with a base 8, one side of the rotor 3 is provided with a temperature sensor 9 and one side of the temperature sensor 9 is provided with a controller 901, the base 8 is provided with a mounting plate 11 and the mounting plate 11 The middle part is provided with a micromotor 10, one end of the micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com