Motor

A technology for motors and rotating parts, applied in the shape/style/structure of the magnetic circuit, electromechanical devices, and rotating parts of the magnetic circuit, etc., which can solve problems such as malfunction of electronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

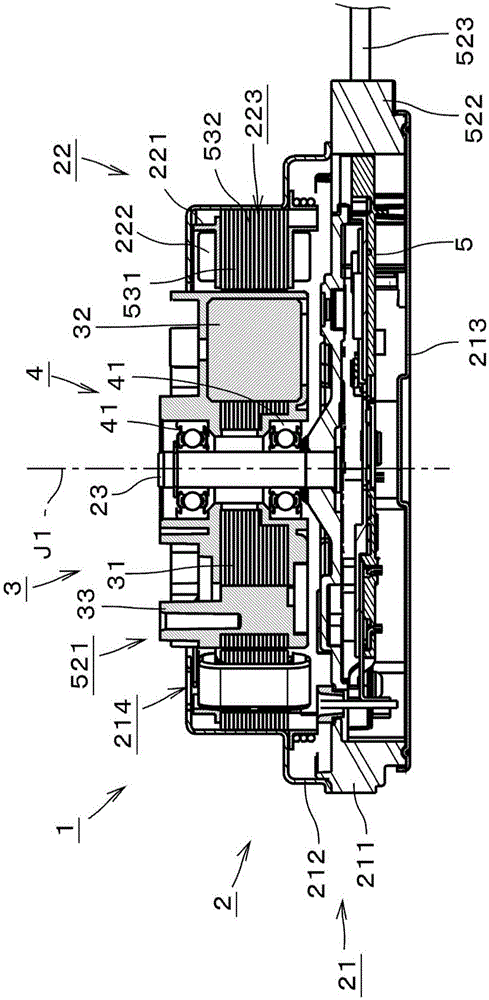

[0056] In this specification, the direction of the central axis J1 of the motor 1 figure 2 The upper side is simply referred to as "upper side", and the lower side is simply referred to as "lower side". In addition, the up-down direction does not indicate the positional relationship and direction when it is incorporated into an actual device. In addition, the direction parallel to the central axis J1 is referred to as "axial direction", the radial direction centered on the central axis J1 is simply referred to as "radial direction", and the circumferential direction centered on the central axis J1 is simply referred to as "circumferential direction". .

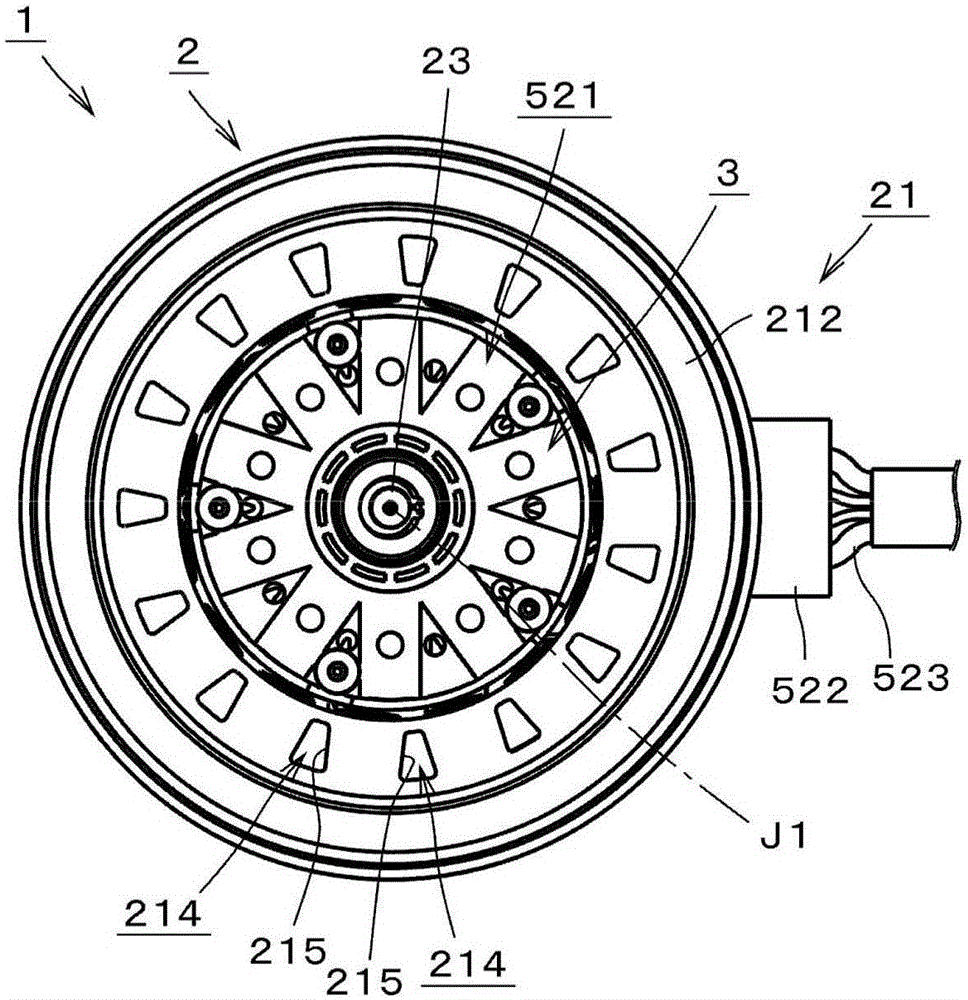

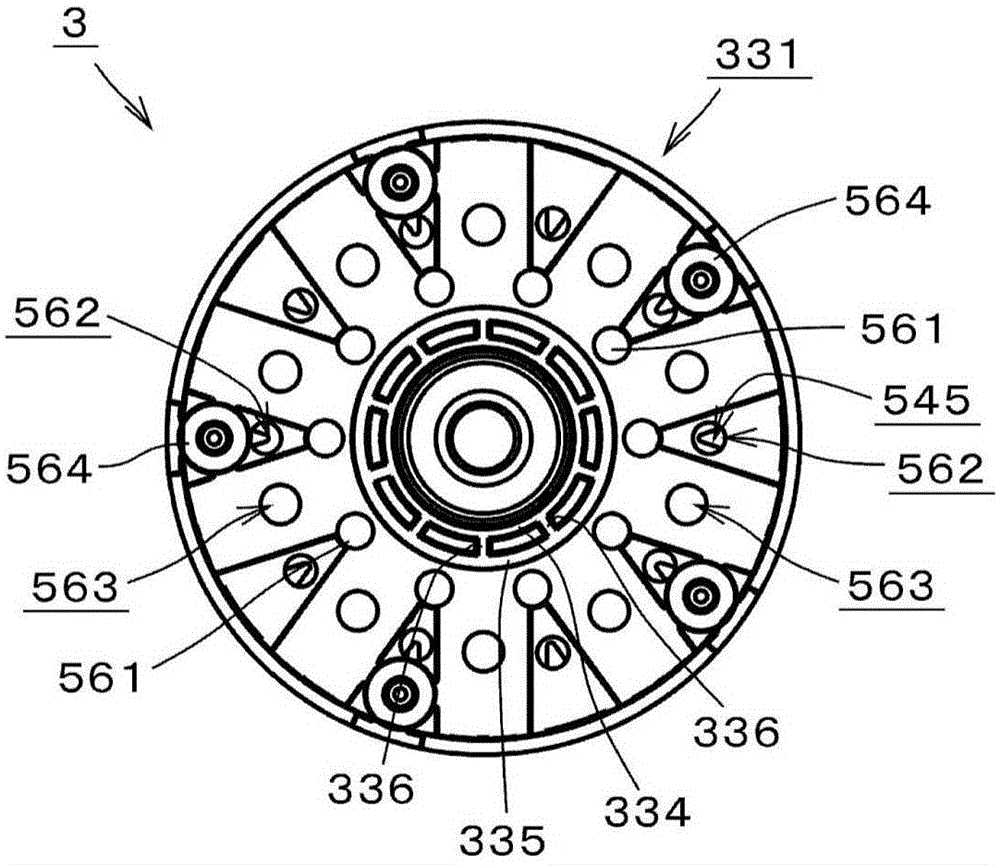

[0057] figure 1 It is a plan view showing a motor 1 according to an exemplary embodiment of the present invention. figure 2 is a longitudinal sectional view of the motor 1 . Parallel slanted lines in minute parts in the cross section are omitted. The motor 1 is an inner rotor type brushless motor. The motor 1 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com