Stage-by-stage mixing-induced fermentation method of collagen

A collagen and mixed induction technology, applied in the field of protein engineering, can solve the problems of autolysis and death of bacterial cells, protein expression limit, bacterial toxicity, etc., to increase the intensity of induction, increase the fermentation unit, and stabilize the strain. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The stage-by-stage mixing induction fermentation method of collagen of the present invention comprises the following steps:

[0033] (1) Purification and preservation, activation and expansion of strains;

[0034] (2) Seed culture in shake flasks and seed tanks;

[0035] (3) Bacteria cultivation and methanol acclimatization in the fermenter, initial induction stage and mixing and increasing induction stage;

[0036] Bacterial culture in the fermenter:

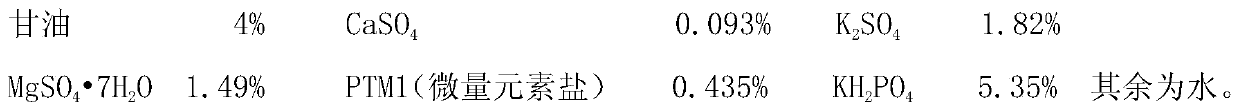

[0037] Prepare FBS medium, calibrate the pH electrode, calibrate the dissolved oxygen electrode, sterilize, cool down to 30°C, and pay attention to the loss of water evaporation. Insert feed bottles: ammonia bottle, defoamer bottle. Feed 50% glycerin and methanol; calibrate the peristaltic pump, accurately measure the injection volume; set the rotation speed at 300rpm, the air ventilation rate at 1.0L / (L min), the temperature at 30°C, the pH at 5.0, and the temperature is automatically controlled; Water pump cascade ...

Embodiment 2

[0050] The stage-by-stage mixing induction fermentation method of collagen of the present invention comprises the following steps:

[0051] (1) Purification and preservation, activation and expansion of strains;

[0052] (2) Seed culture in shake flasks and seed tanks;

[0053] Pick a single colony and insert it into a shaker flask, and cultivate it for 24h under the condition of 30°C and 220rpm at a temperature of 30°C, then insert it into a seed tank, and the inoculum size is 3%. Before inoculation, add 4.35ml sterile PTM1 ( Trace element salts); access to shake flask fermentation broth, microscopic inspection is required for each bottle before access, the temperature is 30°C, the pH is 5.0, the initial rotation speed is 300rpm, the air ventilation rate is 1.0L / (L min), the tank The pressure is 0.05MPa, the air flow is 1.0L / (L min), every 4h, aseptic sampling is taken to measure OD600, wet weight, and the purity of microscopic examination. After a lag period of 5-8h, the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com