Waxing device with automatic wax supplement function

A functional and automatic technology, applied in vehicle maintenance, vehicle maintenance/repair, transportation and packaging, etc., can solve the problems of low waxing efficiency and troublesome operation, and achieve the effects of avoiding wax solidification, saving time and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

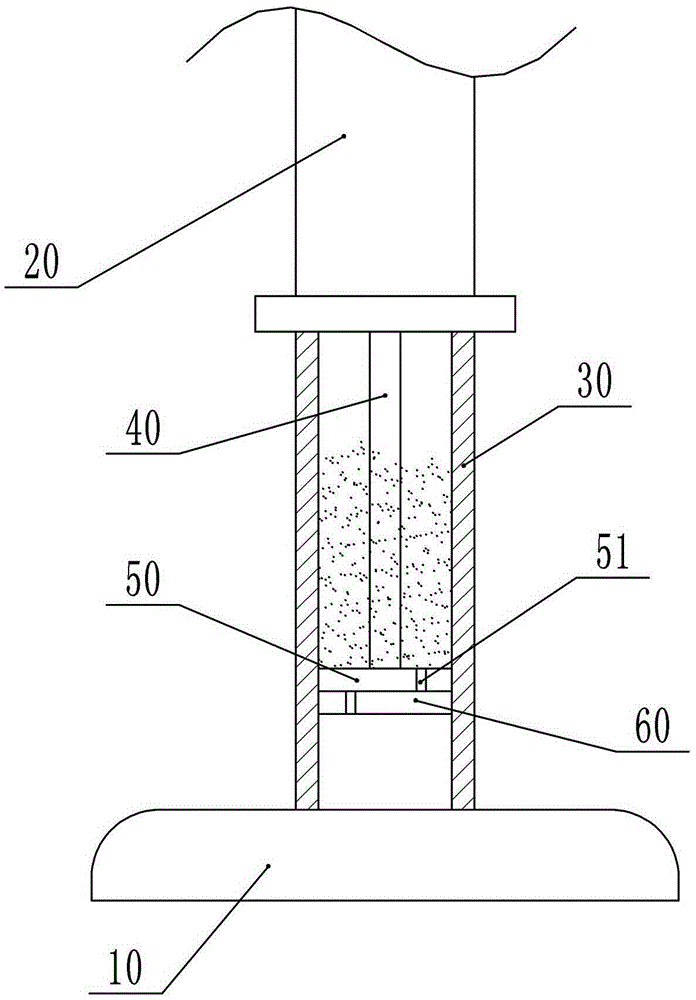

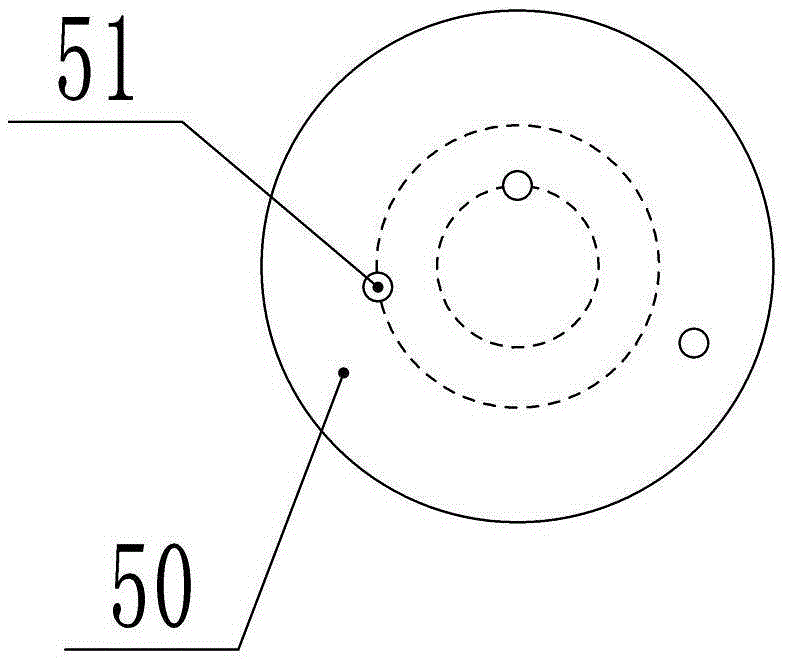

[0015] The reference numerals in the accompanying drawings of the specification include: waxing brush 10 , output shaft 20 of motor, storage tank 30 , connecting rod 40 , first baffle 50 , discharge hole 51 , and second baffle 60 .

[0016] Such as figure 1 , figure 2 As shown, the waxer with automatic wax replenishment function includes a motor, a waxing brush 10, a storage tank 30, a connecting rod 40 and a first baffle 50 and a second baffle 60 that can seal the storage tank 30 . The lower end of the material storage cylinder 30 communicates with the waxing brush 10, and the upper end is coaxially connected with the output shaft 20 of the motor. The first baffle plate 50 and the second baffle plate 60 are each provided with three discharge holes 51 , and the discharge holes 51 on the first baffle plate 50 and the second baffle plate 60 are provided correspondingly....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com