Reverse blasting excavation method of shaft and pilot shaft

A technology for guide shafts and shafts, which is applied in blasting, shaft equipment, reverse sinking, etc., which can solve problems such as large safety risks, manual loading of blasting slag, and restrictions on use conditions, so as to expand the effect of cutting and improve The effect of small disturbance in the construction operation environment and rock mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

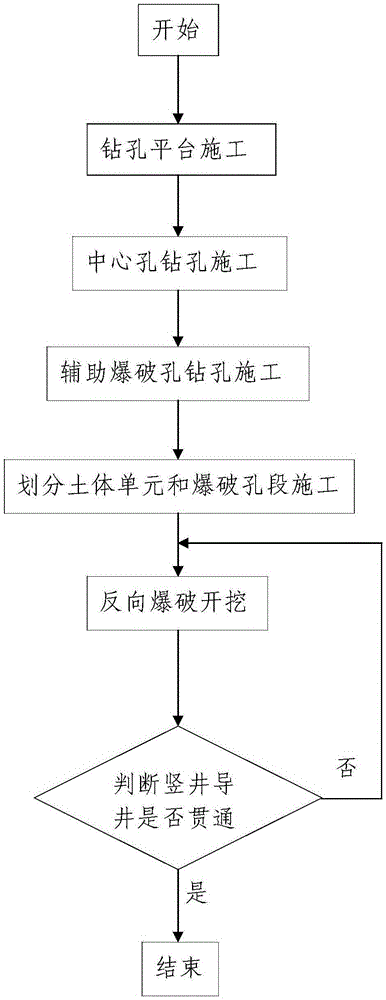

[0063] Such as figure 1 A reverse blasting excavation method for a shaft pilot shaft shown, comprising the following steps:

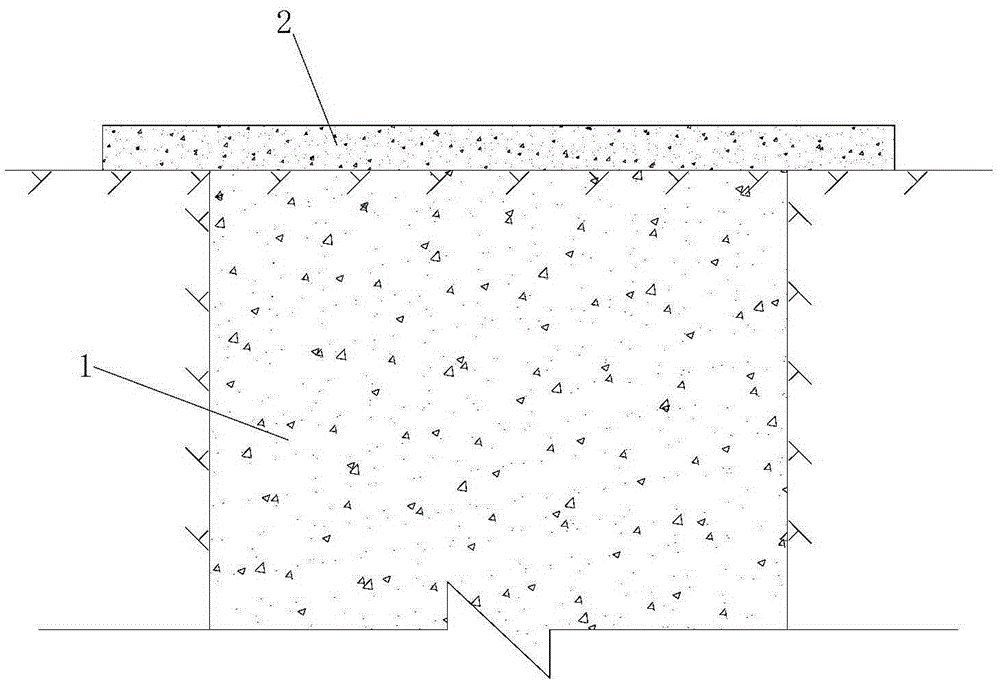

[0064] Step 1, construction of the drilling platform 2: setting the drilling platform 2 on the top surface of the soil body 1 to be excavated in the shaft guide shaft;

[0065] Such as figure 2 As shown, in this embodiment, the drilling platform 2 is poured with concrete on the top surface of the soil body 1 to be excavated in the shaft guide shaft, and the concrete strength grade of the drilling platform 2 is C20, and the concrete The pouring range is 1m beyond the range of the soil body 1 to be excavated in the shaft guide shaft, the thickness of the drilling platform 2 is 20cm, and the flatness of the top surface of the platform is less than 5mm.

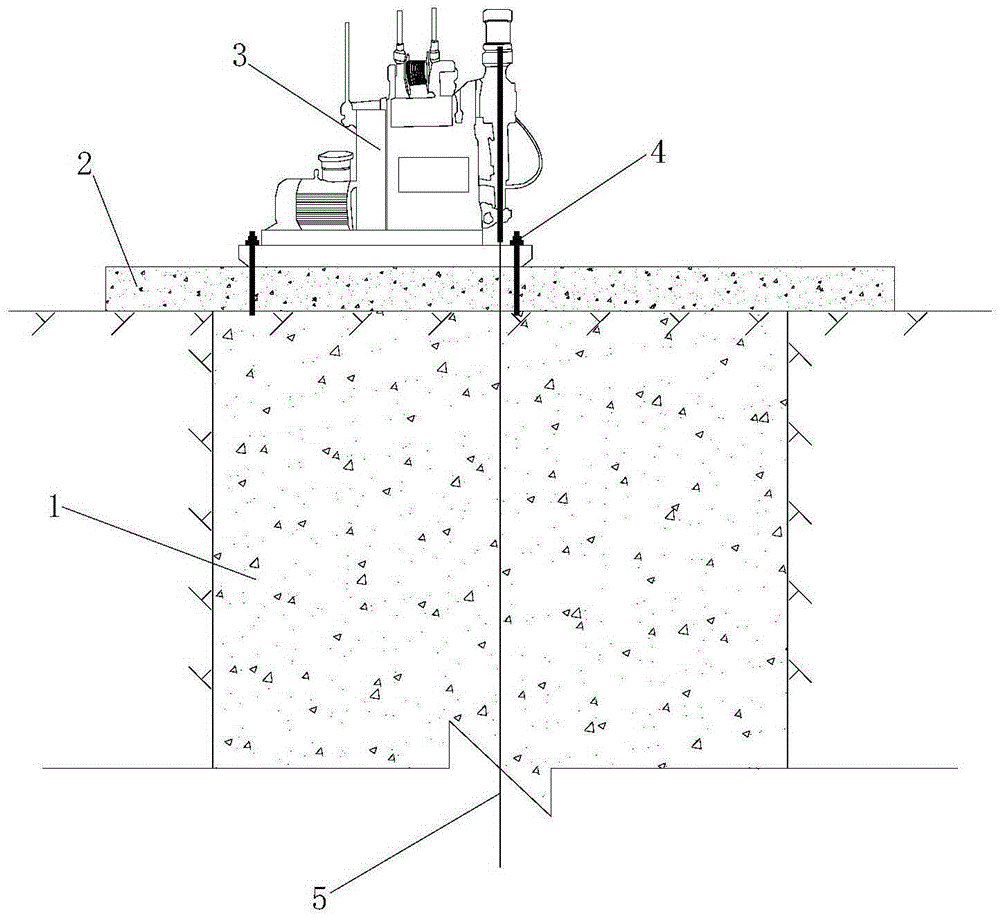

[0066] Step 2, drilling construction of the center hole 6: drill the center hole 6 on the drilling platform 2, and the center hole 6 passes through the drilling platform 2 and the The shaft guide shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com