Intelligent assembling and locking device for circuit board

A locking device and circuit board technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of increased circuit board manufacturing cost, extra space cost, inconvenient centralized storage and transportation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

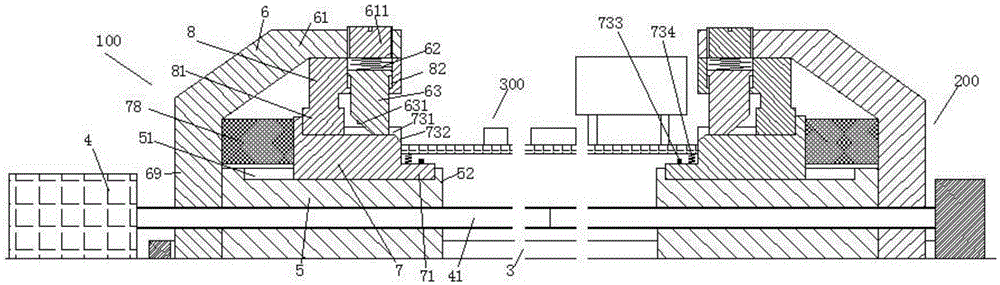

[0009] Combine below figure 1 The present invention will be described in detail.

[0010] According to an embodiment, a smart installation and locking device for a circuit board 300 includes a drive motor 4 fixedly connected to a base frame, a drive screw 41 power-coupled with the drive motor 4, and a rotation direction on the drive screw 41 The left mounting assembly 100 and the right mounting assembly 200 driven by the opposite two sections of thread respectively, and the guide rail 3 that is fixedly connected to the base frame and guides the left mounting assembly 100 and the right mounting assembly 200, wherein the The left mounting assembly 100 and the right mounting assembly 200 are arranged symmetrically, and each includes: a threaded base 5 threadedly fitted with the drive screw 41, a fixing frame 6 fixedly connected to the outer end of the threaded base 5, and The mounting bearing block 7 slidable in the rail groove 51 on the upper side of the threaded base 5, the pushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com