Cabinet vacuum device

A vacuum cleaner, cabinet-type technology, applied in vacuum cleaners, exhaust diffusion devices, suction filters, etc., can solve the problems of small dust bucket capacity, weak air duct suction, complex structure, etc., to increase the dust bucket volume, prevent The effect of machine shaking and high air purification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

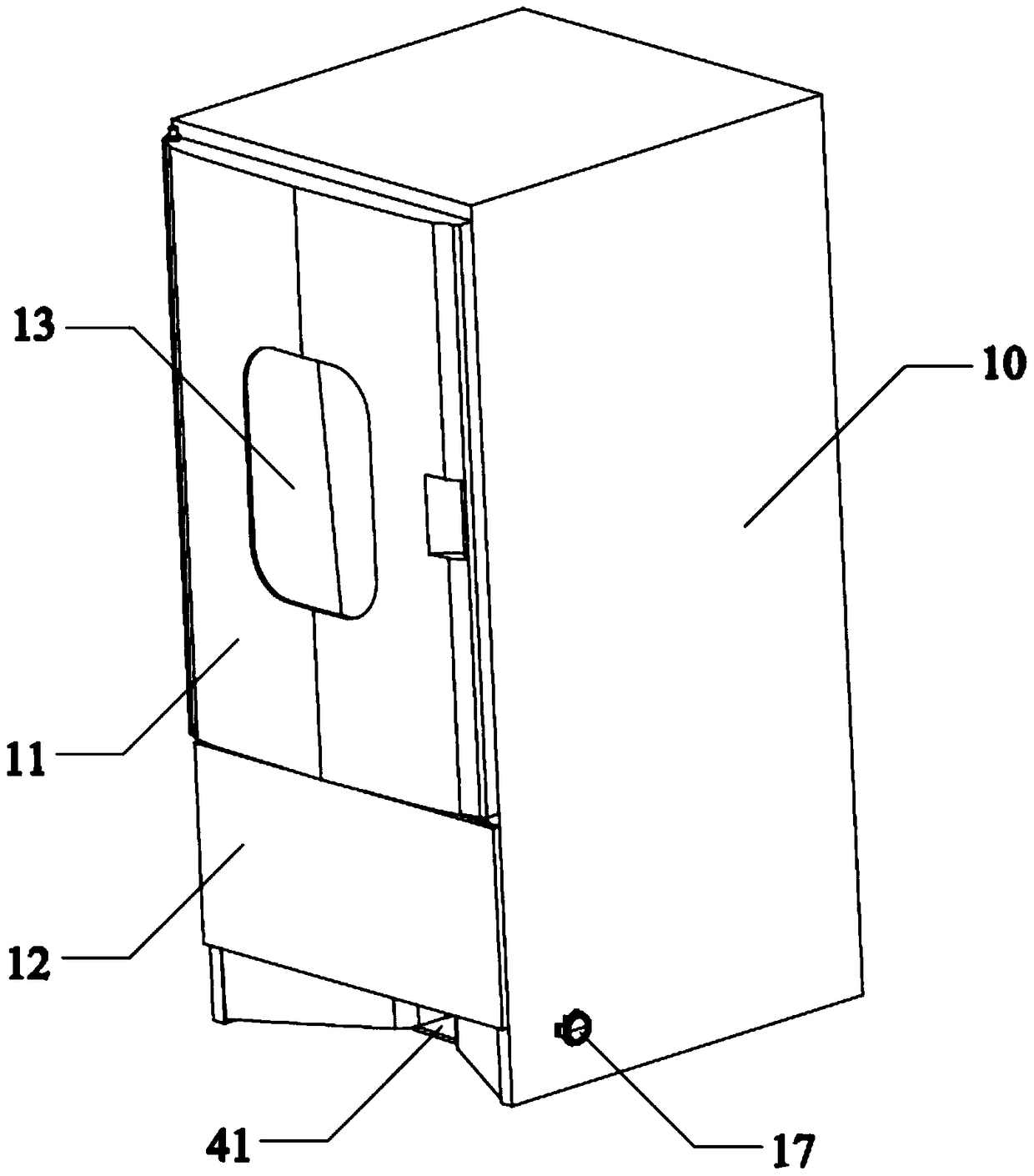

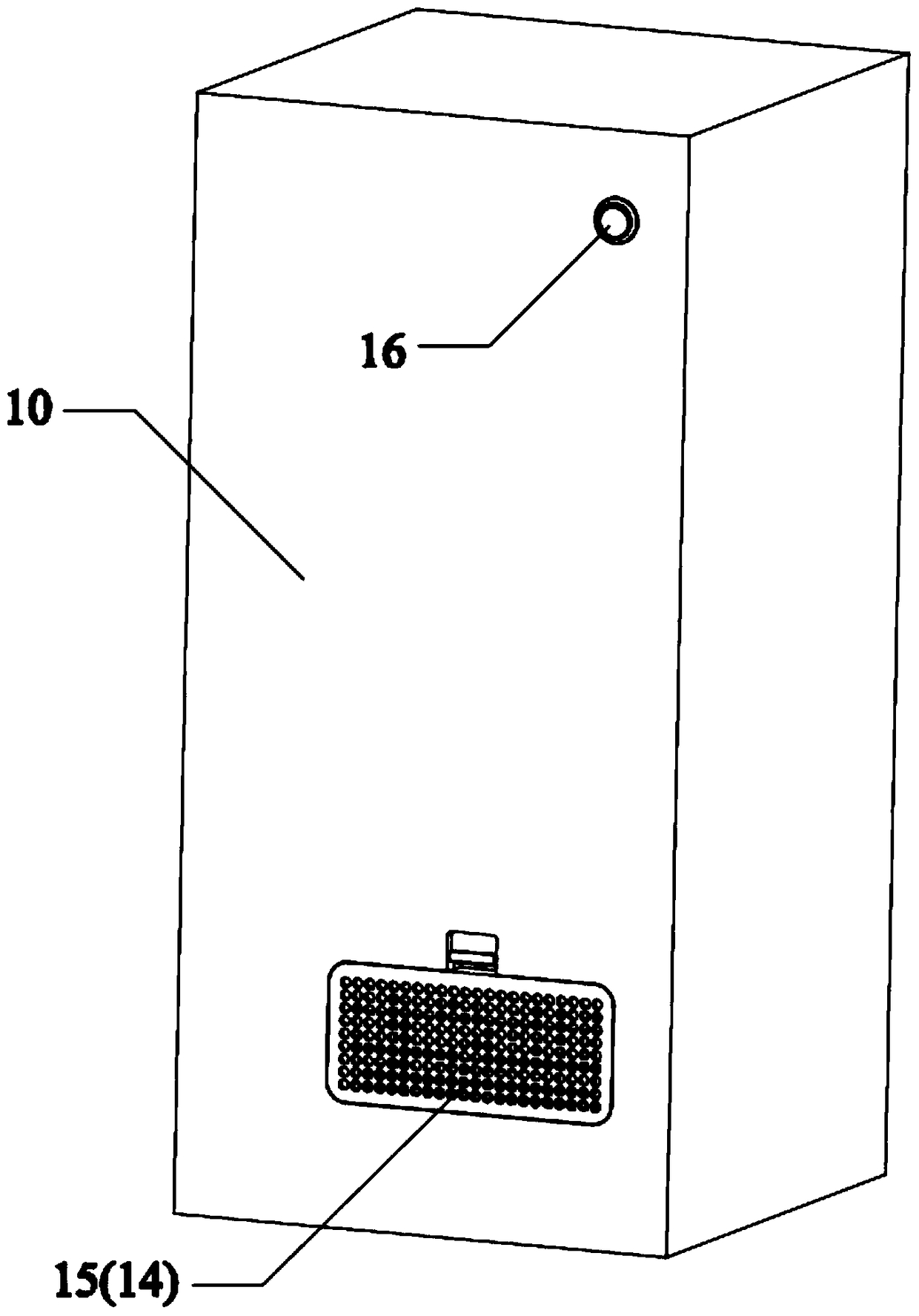

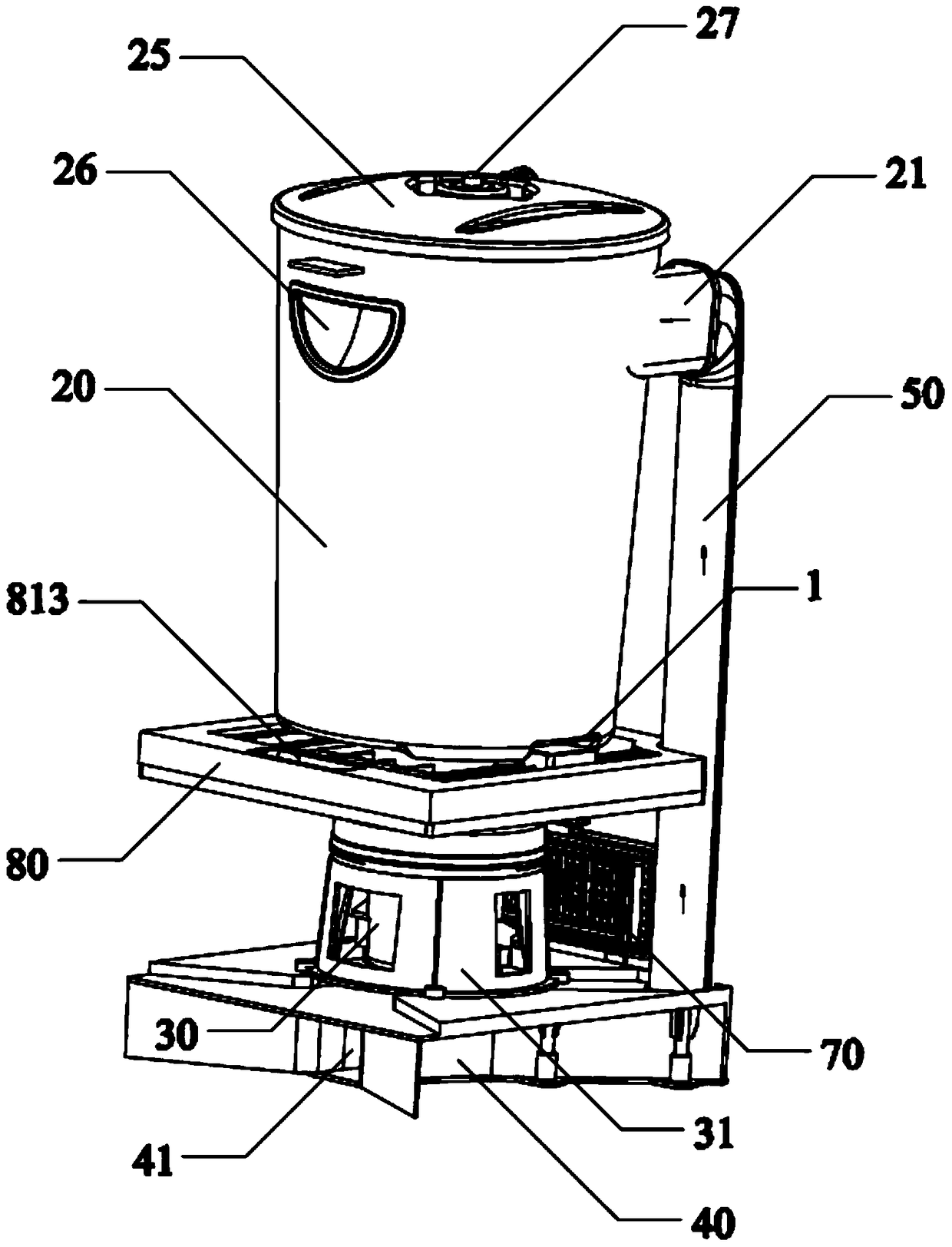

[0049] Refer below Figure 1-Figure 10 Describe in detail an embodiment of the cabinet type dust collection device provided by the present invention; as shown in the figure, this embodiment mainly includes:

[0050] A cabinet body 10 with a switch door 11 is provided. The cabinet body 10 is provided with a dust bucket 20, a motor 30, and a suction base 40 with a suction port 41 in sequence from top to bottom, and the suction base 40 is installed vertically The air inlet duct 50 communicates with the air inlet 21 located at the top of the dust bucket 20;

[0051] The inside of the dust bucket 20 is provided with an air outlet duct 22 that is coaxial with the dust bucket 20 from the bottom up. The inside of the top of the bucket 20, so that an annular cyclone chamber is formed on the inner upper part of the dust bucket 20, and an annular dust collection chamber is formed on the inner bottom;

[0052] The top of the air outlet duct 22 communicates with the cyclone chamber throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com