Self-balancing electric brush

An electric brush and self-balancing technology, applied in the field of brushes, can solve the problems of displacement, easy wrinkling and knotting on the surface of objects, and difficult control of the brush head, and achieve the effect of easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

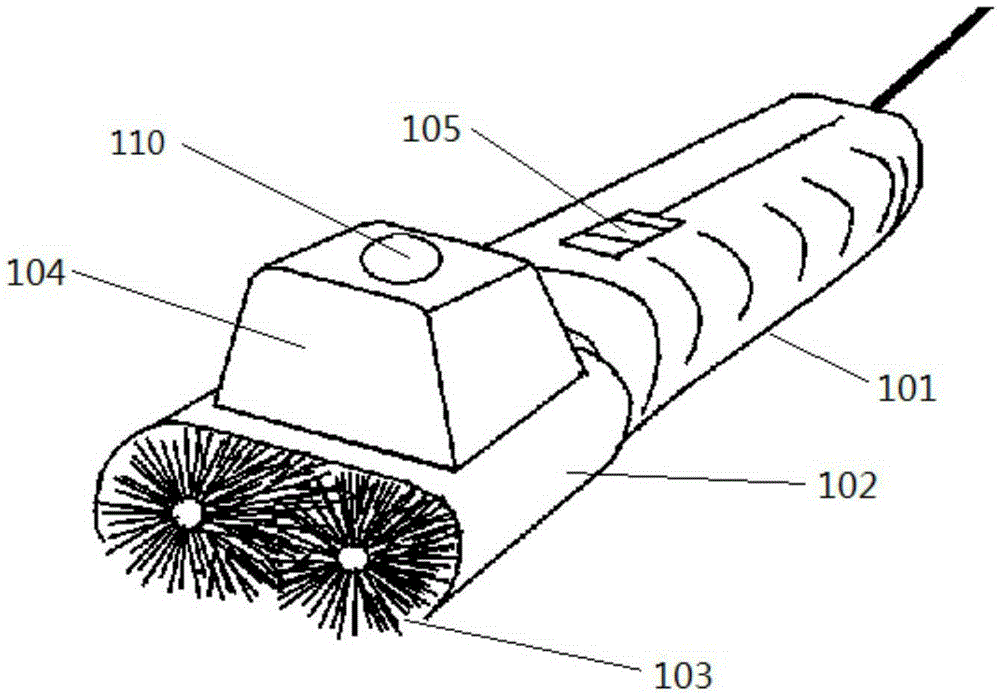

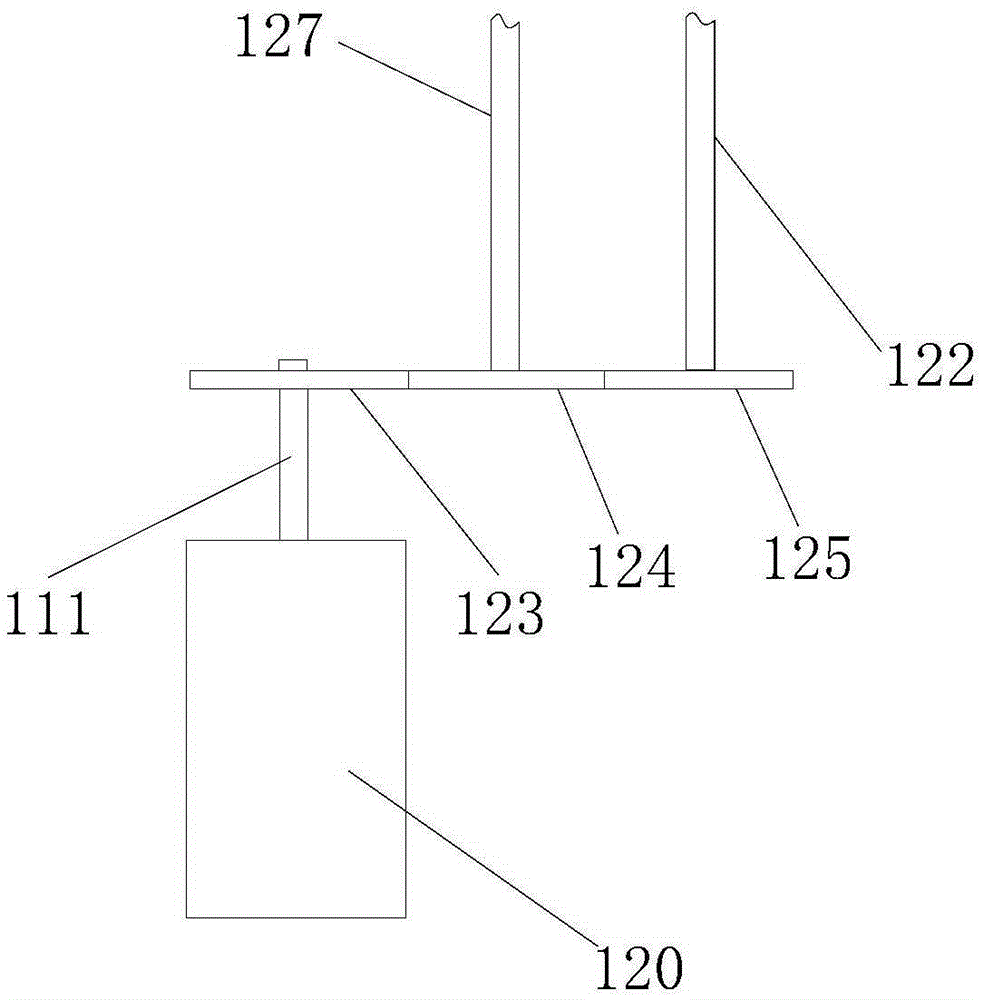

[0058] Example 1, such as Figure 1-Figure 3 as shown,

[0059] The self-balancing electric brush includes a handle 101, a power unit 120 and at least one brush head group 103, the power unit 120 is arranged in the handle 101, the output shaft 111 of the power unit 120 is connected with the brush head group 103, and the brush head group 103 is included in the working When rotating the first brush head 126 and the second brush head 128 in opposite directions. The power unit 120 includes a transmission device connected to the output shaft 111. The transmission device includes a turntable 123, a first gear 124, a second gear 125, a first shaft 122 and a second shaft 127. The turntable 123 is connected to the output shaft 111 and is connected to the first The gears 124 mesh with each other, the second gear 125 and the first gear 124 mesh with each other, the first gear 124 and the second gear 125 are fixedly connected axially to the first rotating shaft 122 and the second rotatin...

Embodiment 2

[0061] Example 2, such as Figure 4-Figure 6 as shown,

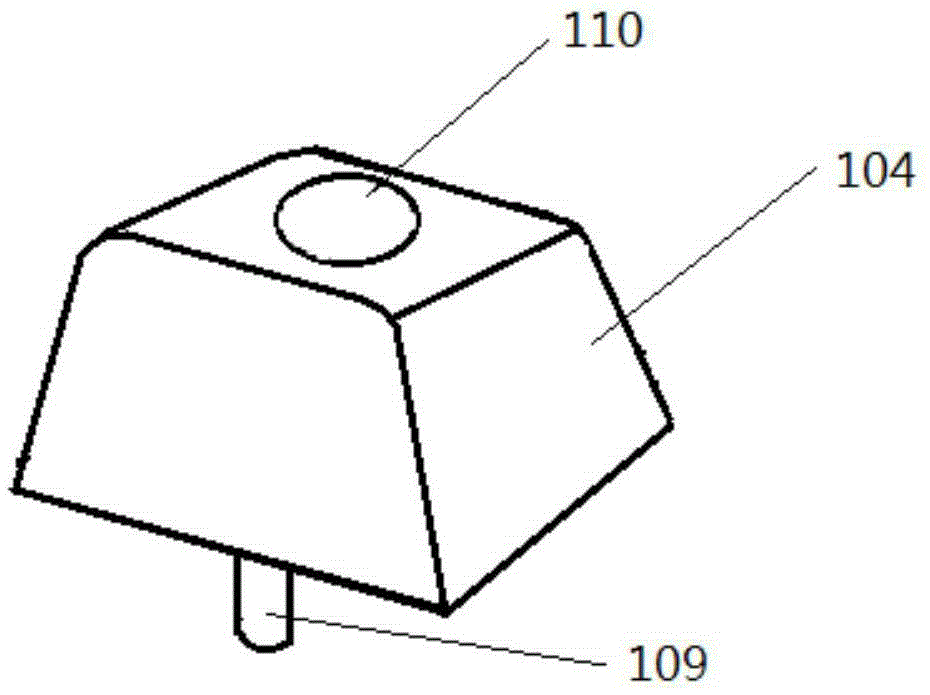

[0062] The self-balancing electric brush includes a handle 101, a power unit 120 and at least one brush head group 103, the power unit 120 is arranged in the handle 101, the output shaft 111 of the power unit 120 is connected with the brush head group 103, and the brush head group 103 is included in the working When rotating the first brush head 126 and the second brush head 128 in opposite directions. The power unit 120 includes a first power unit and a second power unit, and both the first power unit and the second power unit are connected with a reduction gearbox 121, and the first brush head 126 and the second brush head 128 are sleeved on the first power unit respectively. On the output shaft 111 of the reduction gearbox 121 of the device and the output shaft 111 of the reduction gearbox 121 of the second power plant.

[0063] The self-balancing electric brush also includes a lotion box 104 , the bottom of the lot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com