Multi-stage blocking double-ended observation system

A technology of observation system and detection system, which is used in surveying, wellbore/well components, earthwork drilling, etc., to avoid damage, increase measurement ends, and improve measurement efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below with reference to specific embodiments.

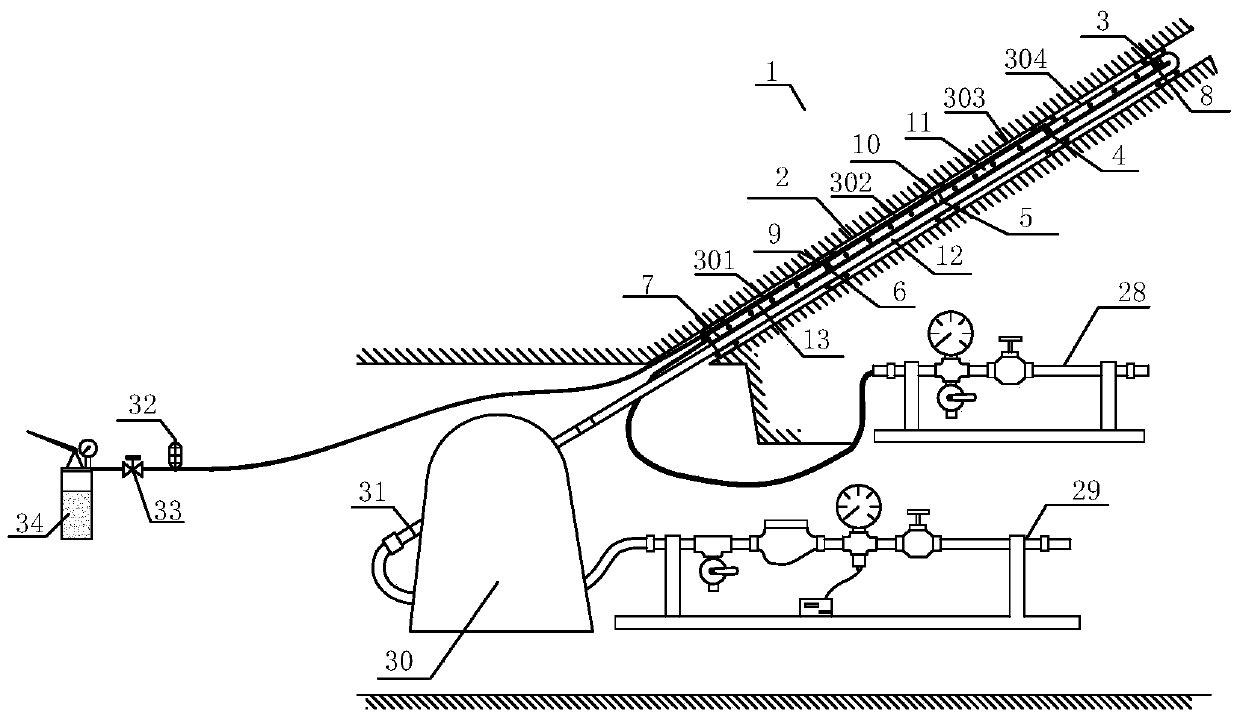

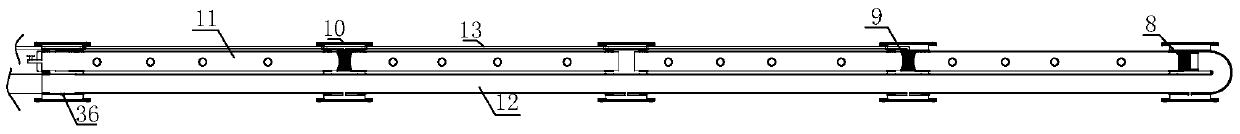

[0048] In the present invention, the multi-stage plugging double-end observation system is such as figure 1 shown, including observation system, blocking system and supply propulsion system, the observation system is a multi-stage observation, which is composed of figure 2 As shown, the observation system is mainly composed of a first detection unit 301, a second detection unit 302, a third detection unit 303 and a fourth detection unit 304, wherein each detection unit includes a leaking water pipe 11, a communication pipe 12, and a third detection unit 303. The head of the four detection units 304 is provided with a slot connector 3, the fourth detection unit 304 and the third detection unit 303 are connected by the slot connector 2 4, and the third detection unit 303 and the second detection unit 302 are connected by a card slot The slot connector 35 is connected, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com