A method of producing variable cycle fabrics by using fixed jacquard manufacturing process

A fabric and craft technology, applied in the field of jacquard fabric production technology, can solve problems such as pattern layout restrictions, and achieve the effects of low equipment requirements, obvious effects, and short production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

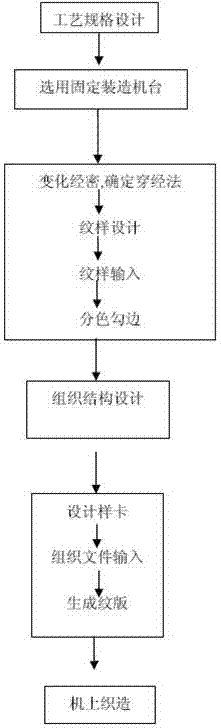

Method used

Image

Examples

Embodiment 1

[0061] Example 1 (when the fixed full wear machine does not change)

[0062] Fixed warp density on the machine: 110 threads / cm;

[0063] Weft shrinkage=4%;

[0064] Number of needles in a pattern (n) = 1200 (needles);

[0065] The first 600 stitches of weave are 5 pieces of weft satin, and the last 600 stitches are 5 pieces of warp satin;

[0066] Then the maximum size of the single cycle return on the machine can only be: (1200 / 110 / cm) / (1+0.04)=10.5cm.

Embodiment 2

[0067] Embodiment 2 (when the heald adopts 1 thread and 1 hole)

[0068] Warp density on the machine: 55 threads / cm;

[0069] Weft shrinkage=4%;

[0070] Number of needles in a pattern (n) = 1200 (needles);

[0071] The first 600 stitches are 5 pieces of weft satin, and the last 600 stitches are 5 pieces of warp and satin. Move the first 600 stitches of weft satin to odd-numbered needles, and the last 600 stitches of warp and satin to even-numbered needles. Thread on odd-numbered needles, and even-numbered flower healds on the machine on even-numbered needles;

[0072] Then the maximum size of the single cycle return on the machine is: (1200 / 55 / cm) / (1+0.04)=21cm.

Embodiment 3

[0073] Embodiment 3 (the heddle adopts positioning to wear)

[0074] Weft shrinkage=4%

[0075] Number of needles for one pattern (n) = 1200 (needles), a total of 6 times on the machine;

[0076] The total width of heald full wear is: (1200 / 110 / cm) X13 / (1 + 0.04) = 136.5 cm; the maximum return position can only be (1200 / 110 / cm) / (1 + 0.04) =10.5 cm.

[0077] Now change the warp line density on the machine to: 55 wires / cm;

[0078] The first 600 stitches and the last 600 stitches are 5 pieces of weft satin, and the middle 6600 stitches are 5 pieces of warp satin. Move the first 600 stitches of weft satin to the odd-numbered needles, and move the last 600 stitches of warp satin to the even-numbered needles. The 1st and 13th flower healds on the machine are threaded on even-numbered needles, and the 2nd to 12th flower healds on the machine are threaded on even-numbered needles;

[0079] Then the maximum size of the single cycle return position on the machine become...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com