A self-locking two-way self-aligning roller set

A self-aligning idler and self-locking technology, applied in the direction of rollers, conveyor objects, transportation and packaging, etc., can solve problems such as belt wear, poor operation reliability, and poor deviation adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

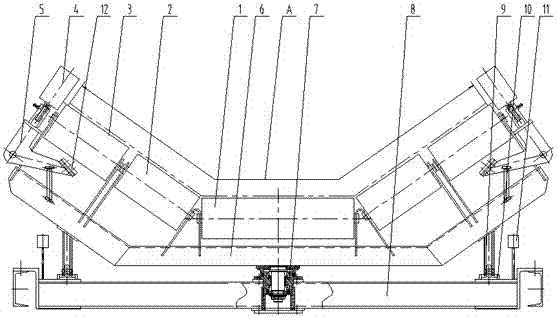

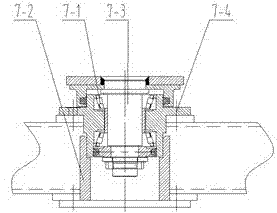

[0013] Referring to the accompanying drawings, a self-locking two-way self-aligning idler roller set includes middle roller 1, side roller 2, side roller 3, retaining roller 4, adjustment arm 5, upper beam 6, slewing device 7, lower beam 8, auxiliary support 9. Rail 10, receiver 11, friction plate 12, the upper beam 6 and the lower beam 8 are connected by the rotary device 7, the middle roller 1 is arranged above the middle of the upper beam 6, and the vertical center line of the upper beam 6 is axisymmetric Set the side roller 2 and the side roller 3, the tape A runs along the middle roller 1, the side roller 2, and the side roller 3 in a groove shape, and the two sides of the upper beam 6 are provided with the adjustment arm 5, and the stop roller 4 is fixed on the adjustment arm 5. Friction plate 12 is arranged below side roller 3 and is contained on the adjustment arm 5, track 10 and receiver 11 are set on lower beam 8, auxiliary support 9 is fixed on the upper beam 6 and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com