Wax mold assembling fixture and assembling method for welding and assembling rotary wax mold parts

A technology of parts welding and rotating body, which is applied in the field of precision casting, can solve the problems of wax pattern combination position size deviation, wax pattern clamping and positioning difficulties, failure to meet the coaxiality requirements of wax pattern combination, etc., to eliminate misalignment and drape seam, solve the problem of dimensional accuracy, and ensure the effect of dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

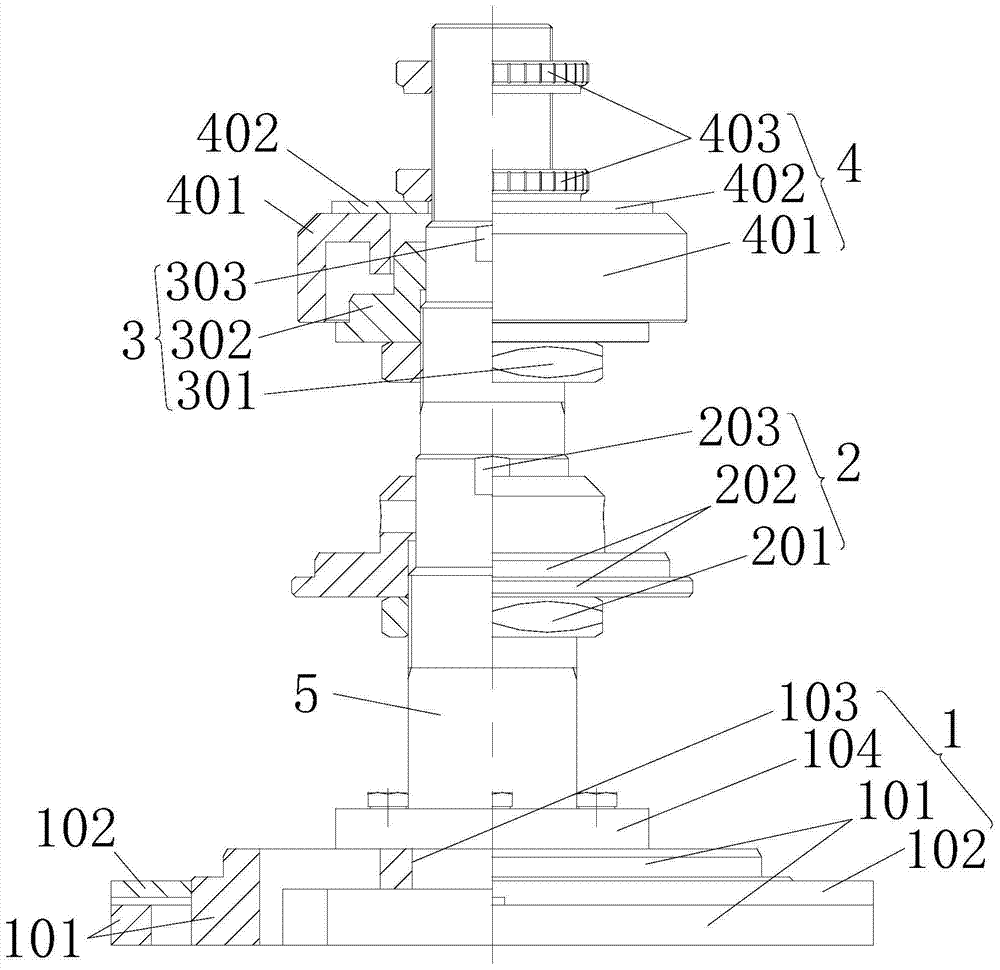

[0021] figure 1 It is a structural schematic diagram of a wax pattern assembling fixture used for welding and assembling wax pattern parts of a rotating body in a preferred embodiment of the present invention.

[0022] Such as figure 1 As shown, the wax pattern assembling fixture used for welding and assembling the rotating body wax pattern parts in this embodiment includes a bottom positioning mechanism 1 for supporting the bottom unit body of the rotating body wax pattern part from the bottom and positioning the bottom unit body, The middle positioning mechanism 2 for the positioning of the middle unit body of the wax model part of the rotating body, the top positioning mechanism 3 for the positioning of the top unit body of the wax model part of the rotating b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com