Automatic weaving-chain welding machine

A welding machine and chain weaving technology, which is applied in the field of chain weaving machines, can solve the problems of large demand for chain machines, irradiation welding, heavy work, etc., and achieve the effect of improving productivity, improving production efficiency, and ensuring the same purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] An embodiment of the present invention is described with reference to the accompanying drawings.

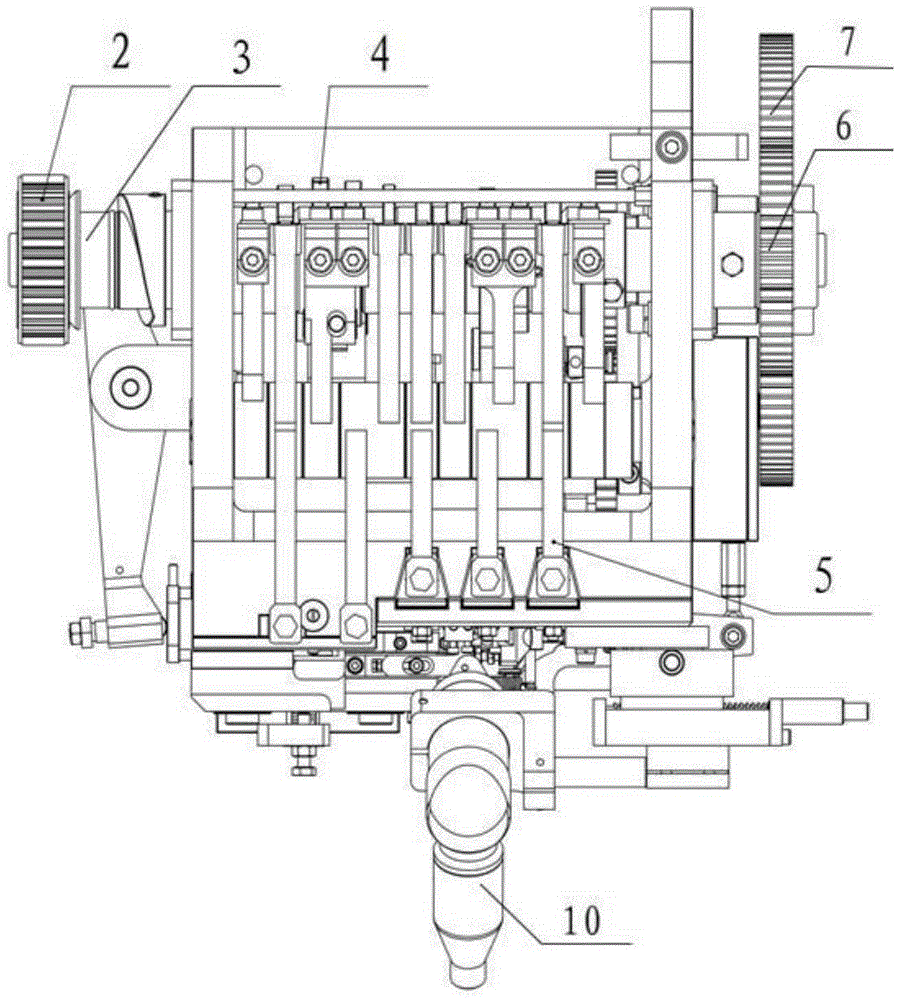

[0025] Automatic chain weaving welding machine, including toothed belt 1, toothed pulley 2, main shaft 3, cam 4, cam swing lever 5, transmission gear 6, disk cam gear 7, sector gear 8, swing lever 9, laser focusing lens 10. The main shaft 3 is installed on the upper part of the machine. One side of the main shaft 3 is equipped with a toothed pulley 2. The toothed belt pulley 2 is connected with the engine through a toothed belt 1. The other end of the main shaft 3 is equipped with a transmission gear 6. The transmission gear 6 It is connected with the disk cam gear 7 through gears, and the disk cam gear 7 is connected with the sector gear 8 through gears. The main shaft 3 is also equipped with a cam 4 and a cam swing lever 5. A laser focusing lens 10 is also installed outside the upper part of the machine. The bottom is equipped with a pendulum 9, and the automatic chain w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com