Single clutch multi-stage automatic transmission

A technology of automatic transmission and one-way clutch, which is applied in transmission control, components with teeth, belts/chains/gears, etc. It can solve the problems of shifting interference, many control programs, and a large number of actuators, etc., and achieve improvement Simple and smooth shifting speed and shifting procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

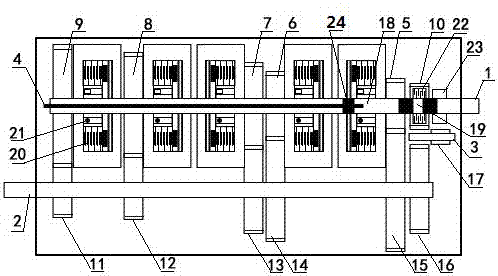

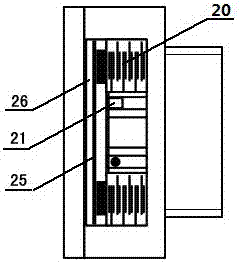

[0021] Such as figure 1 As shown, the power input shaft 1 is equipped with a plurality of driving gears, each driving gear corresponds to a gear position, and the power output shaft 2 is equipped with a plurality of driven gears, and each driven gear corresponds to a gear position; In this embodiment, there are 5 forward gears, and 5 driving gears are installed on the corresponding power input shaft, that is, the first gear driving gear 5, the second gear driving gear 6, the third gear driving gear 7, and the fourth gear driving gear. Gear 8, the fifth gear driving gear 9; the power output shaft 2 is equipped with 5 driven gears correspondingly, that is, the first gear driven gear 15, the second gear driven gear 14, the third gear driven gear 13, the Fourth gear driven gear 12, fifth gear driven gear 11.

[0022] The power input shaft 1 is provided with a shift shaft 4, and one end of the shift shaft is fixed with a piston 24, and the outer side of the piston is a first oil p...

Embodiment 2

[0029] In the second embodiment, the shift shaft is arranged in the power output shaft, and the one-way clutch and the clutch are arranged in the driven gear, and the rest of the structure and working principle are the same as in the first embodiment.

[0030] There is a shift shaft inside the power output shaft, and a piston is fixed at one end of the shift shaft, and the outer chamber of the piston is the third oil pressure chamber for controlling shift; each driven gear is equipped with a one-way clutch and a clutch , the clutch can be controlled by the oil pressure of the third oil pressure chamber to be in the combined state, and the driven gear drives the power output shaft to rotate through the clutch. The one-way clutch in the driven gear is installed on the power output shaft, and the clutch is located on the outside of the one-way clutch; there is also a clutch oil chamber and a clutch piston in the driven gear, and the clutch oil chamber can be connected with the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com