Production technology for preparing premixed dry-mixed mortar from recycled aggregate

A recycled aggregate and dry-mixed mortar technology, applied in the field of building materials, can solve problems such as poor building quality, environmental pollution, and reduced cultivated land, and achieve the effects of improving construction performance, improving mortar quality, and reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific embodiment:

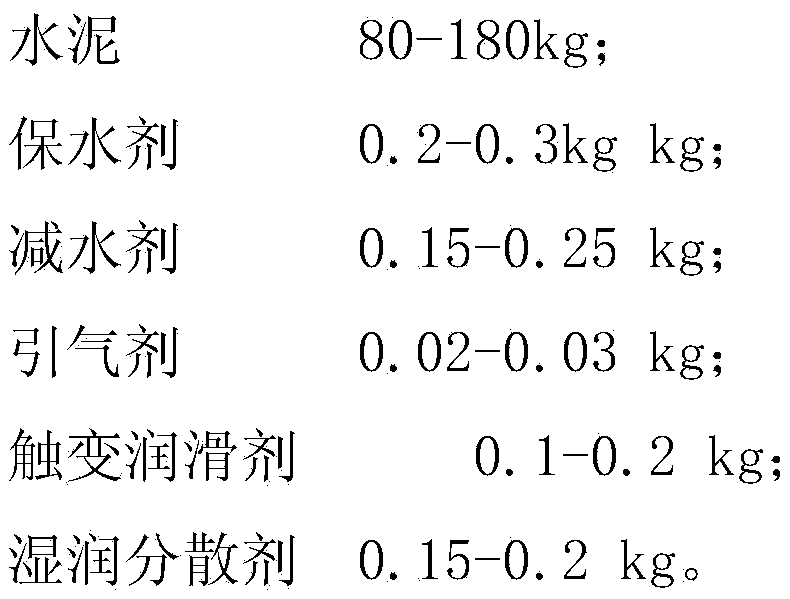

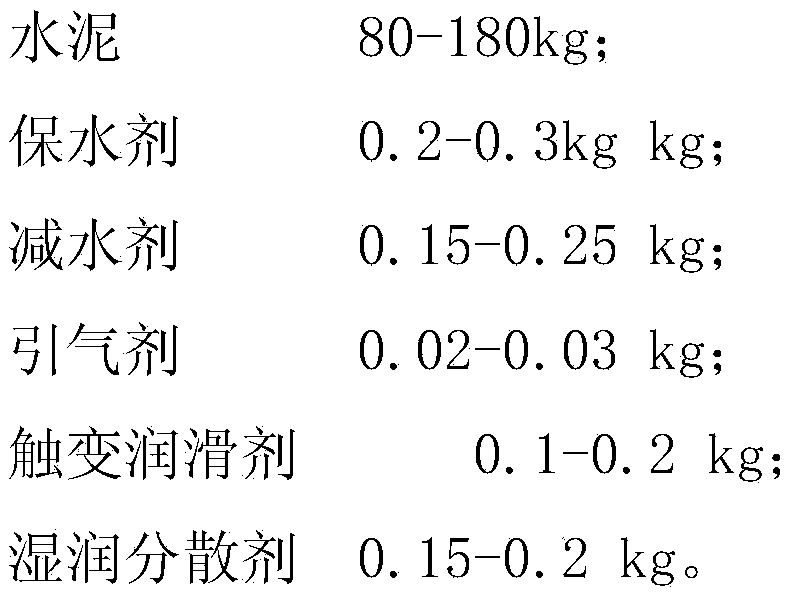

[0022] A production process for preparing ready-mixed dry-mixed mortar from recycled aggregates, comprising the following steps:

[0023] The first step is to classify the construction waste, and take the waste concrete and waste sintered bricks and store them separately;

[0024] The second step is to crush waste concrete and waste sintered bricks to form waste concrete recycled aggregates and waste sintered bricks recycled aggregates; specifically, the crushing includes the early crushing of the crocodile crusher and the crushing of the hammer mill. Post-stage crushing, so as to obtain recycled aggregates with a diameter less than or equal to 2.5mm, and perform secondary crushing on the recycled aggregates larger than 2.5mm to form recycled aggregates with a diameter of 2.5mm or less, and after the crushing is completed, Detect recycled aggregates with a diameter less tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com