Lower mold structure with convenience in mold storage

A mold, convenient technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., to achieve the effect of improving service life and avoiding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in combination with specific embodiments.

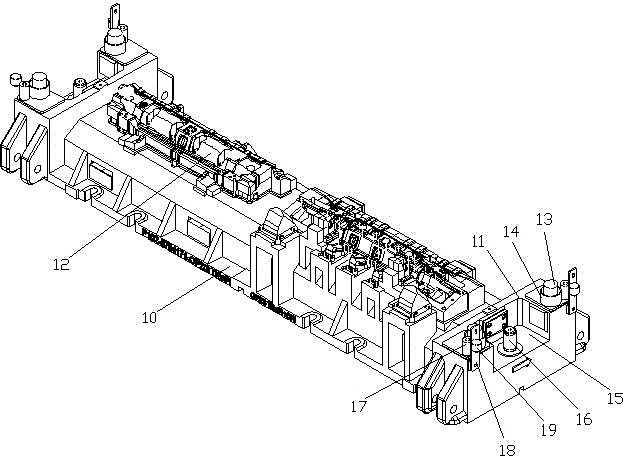

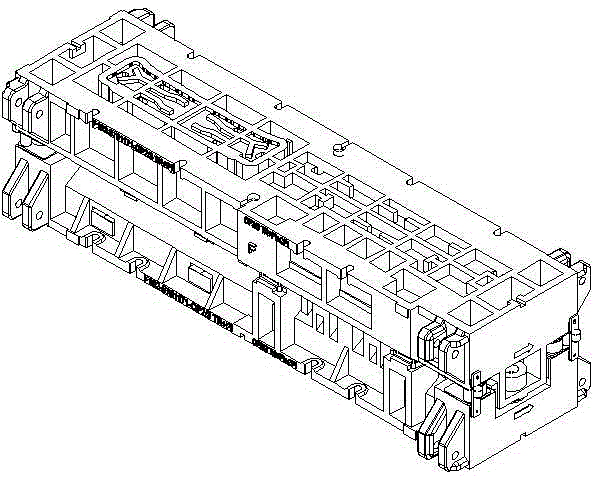

[0013] see figure 1 , as can be seen from the figure, the lower mold structure of the present invention is convenient for mold storage, including a lower mold base 10, a convex body 11 is respectively provided at the left and right ends of the lower mold base 10, and a lower mold main body 12 is formed between the two convex bodies 11. Buffer columns 13 are respectively arranged at the front and rear positions on the upper surface of each convex body 11. The buffer columns 13 are processed by polyurethane. The buffer columns 13 are provided with a sheath 14. A post emerges from the sheath. On the convex body between the two sheaths 14, there is a notch 15 with open upper surface and outer surface, and a guide post 16 is arranged in the middle of the notch 15 . Corresponding limiting posts 17 are provided on the convex bodies 11 outside the two sheaths. Two connecting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com