Image acquisition-based lubricating oil abrasive particle on-line monitoring device and work method thereof

An image acquisition and monitoring device technology, which is applied in the field of ferrography online analysis in lubricating oil, can solve problems such as occlusion, and achieve the effect of solving occlusion phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

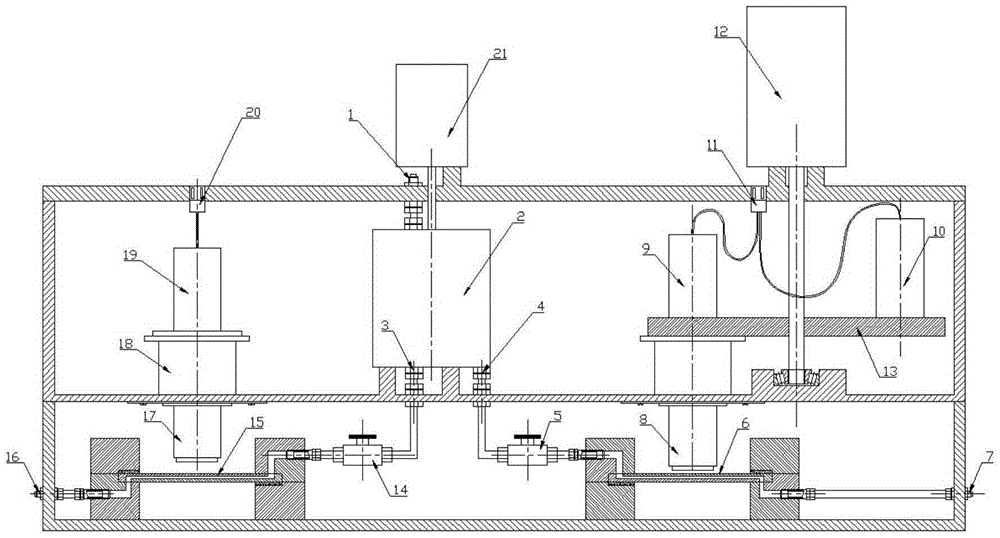

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] Such as figure 1 Shown is an online monitoring device for lubricating oil abrasive particles based on image acquisition, including an oil separation system and an image acquisition system. The oil separation system separates the oil according to the size of the abrasive particles contained in the oil. Two groups of oils are separated: the oil with the abrasive particle size less than 15um and the oil with the abrasive particle size greater than or equal to 15um, and the two groups of oils are respectively collected by the image acquisition system for the number of abrasive particles and the shape of the abrasive particles. Classify the abrasive particles according to the size, reduce the thickness of the deflector while ensuring that the flow channel is not blocked, reduce the depth of field and improve the stability of the oil flow; at the same time, the partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com