Tail rope tensioning device for vertical shaft hoisting container

A tensioning device and container technology, applied in elevators, transportation and packaging, etc., can solve the problems of large tail rope swing, large safety hazards, kinks, etc., to achieve the effect of mine hoisting operation being safer and more reliable and preventing safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

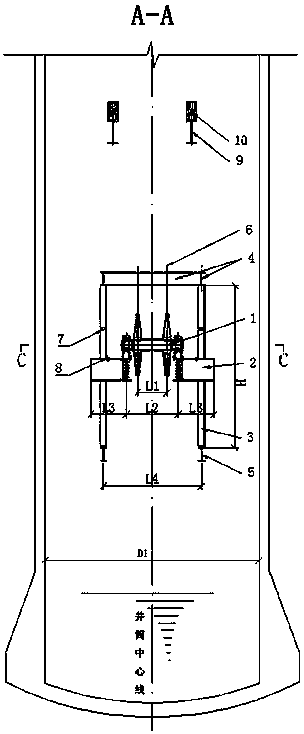

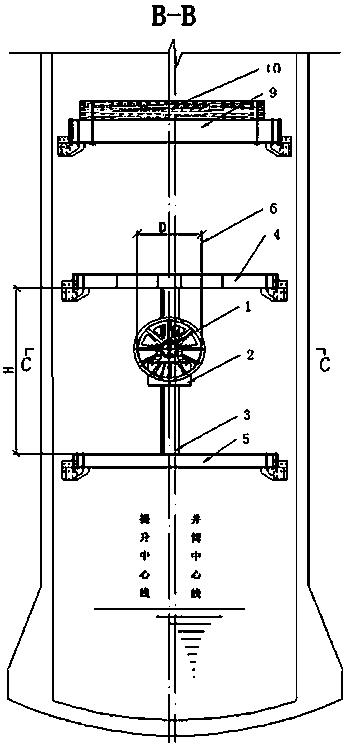

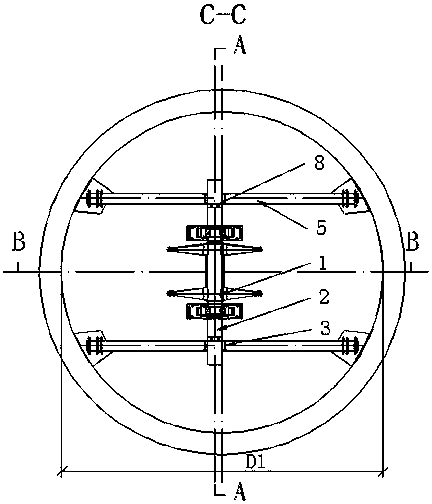

[0025] Such as Figure 1 to Figure 5 As shown, a tail rope tensioning device for a shaft lifting container includes a guide wheel mechanism 1. The guide wheel mechanism 1 includes a pair of guide wheels. The diameter of the guide wheels is equal to the distance between the two lifting containers or the central axis of the lifting container and the counterweight. The two ends of the guide wheel mechanism 1 are respectively fixed on a pair of movable guide wheel supports 2, and the movable guide wheel supports 2 are placed between two guide columns 3 to limit the direction of the guide wheels in the horizontal direction perpendicular to the axis of the guide wheels. Free movement on the top, while the spacing between the guide columns 3 is matched with the movable guide wheel support 2 placed therebetween, so that the support can slide freely up and down inside it. The upper end of the guide column 3 is connected with the anti-kink beam 4, and the lower end is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com