Supporting and hoisting mechanism provided with sensor and used for mixing head in foaming machine

A mixing head and foaming machine technology, applied in the field of supporting and hoisting mechanisms, can solve the problems of difficult parameters such as temperature and pressure of polyurethane foaming raw materials, time-consuming and laborious, and increased production costs, so as to reduce production costs, improve production quality, and increase production costs. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

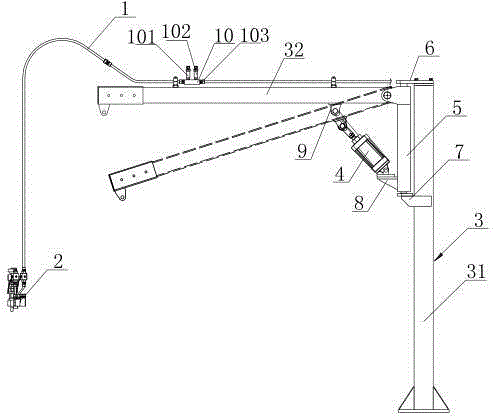

[0013] like figure 1 As shown, the supporting and hoisting mechanism of the mixing head in the foaming machine with sensors includes: a component delivery hard tube 1 that is fixedly connected to the mixing head 2 at one end and communicated with the polyurethane foam raw material barrel at the other end, and the component delivery hard tube 1. It is fixedly installed on the support frame 3. The structure of the support frame 3 includes: a support column 31 and a support boom 32. The inner end of the support boom 32 is hinged on the support column 31. The arm 32 is set and fixedly mounted on the support arm 32, so that the mixing head 2 is supported and hoisted on the outside of the support arm 32, and the support column 31 is hinged with a cylinder 4, and the piston rod of the cylinder 4 is hinged to the support arm 32. Connection,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com