Portable electric rubber tapping knife

A portable, rubber-tapping knife technology, applied in forestry, application, agriculture, etc., can solve the problems of production enterprises that cannot make ends meet, increase labor costs, and there is no one to cut glue, so as to relieve labor tension, reduce labor intensity, and ensure production and benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe in detail the technical content and structural features of the rubber portable electric tapping knife of the present invention, the following will be further described in conjunction with the embodiments and accompanying drawings.

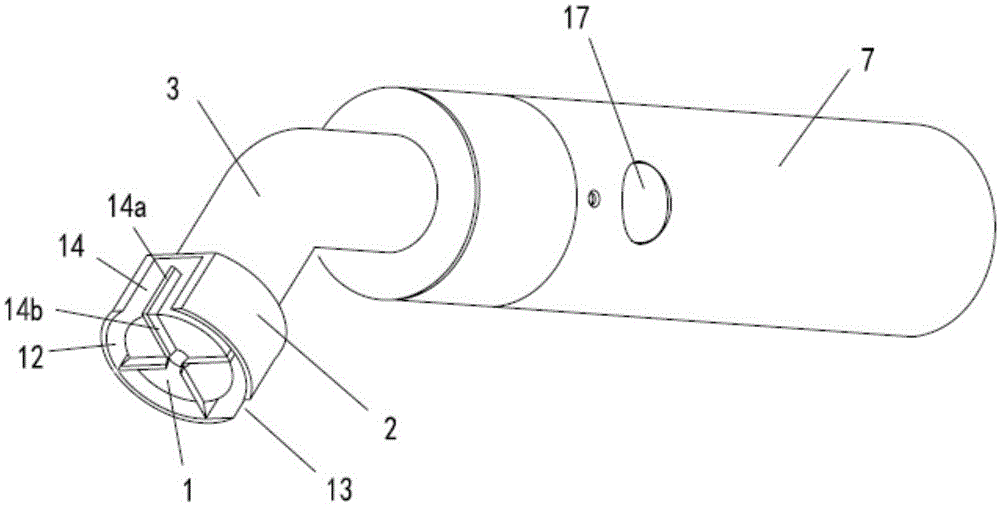

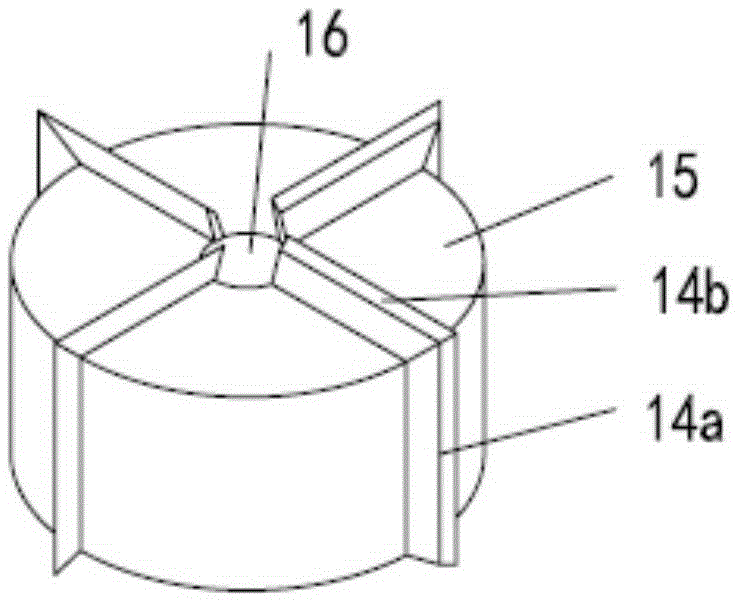

[0027] Such as figure 1 , 2 , 3, 4, and 5, the rubber portable electric tapping knife of the present invention includes a rotary cutter head 1, a limiting device 2, a transmission assembly, a power assembly, an engaging assembly and a handle 7; the limiting device 2 connects with the threaded joint 11 One end of the assembly is connected, and the other end of the connecting assembly is connected with the handle 7, and the connecting assembly is an elbow joint 3. The threaded connection between the limiting device 2 and the elbow joint 3 is set to be rotatable, and the direction of the axial cutting opening 14 can be adjusted.

[0028] The rotary cutter head 1 is placed in the limit device 2, the rotary cutter head 1 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com