tire

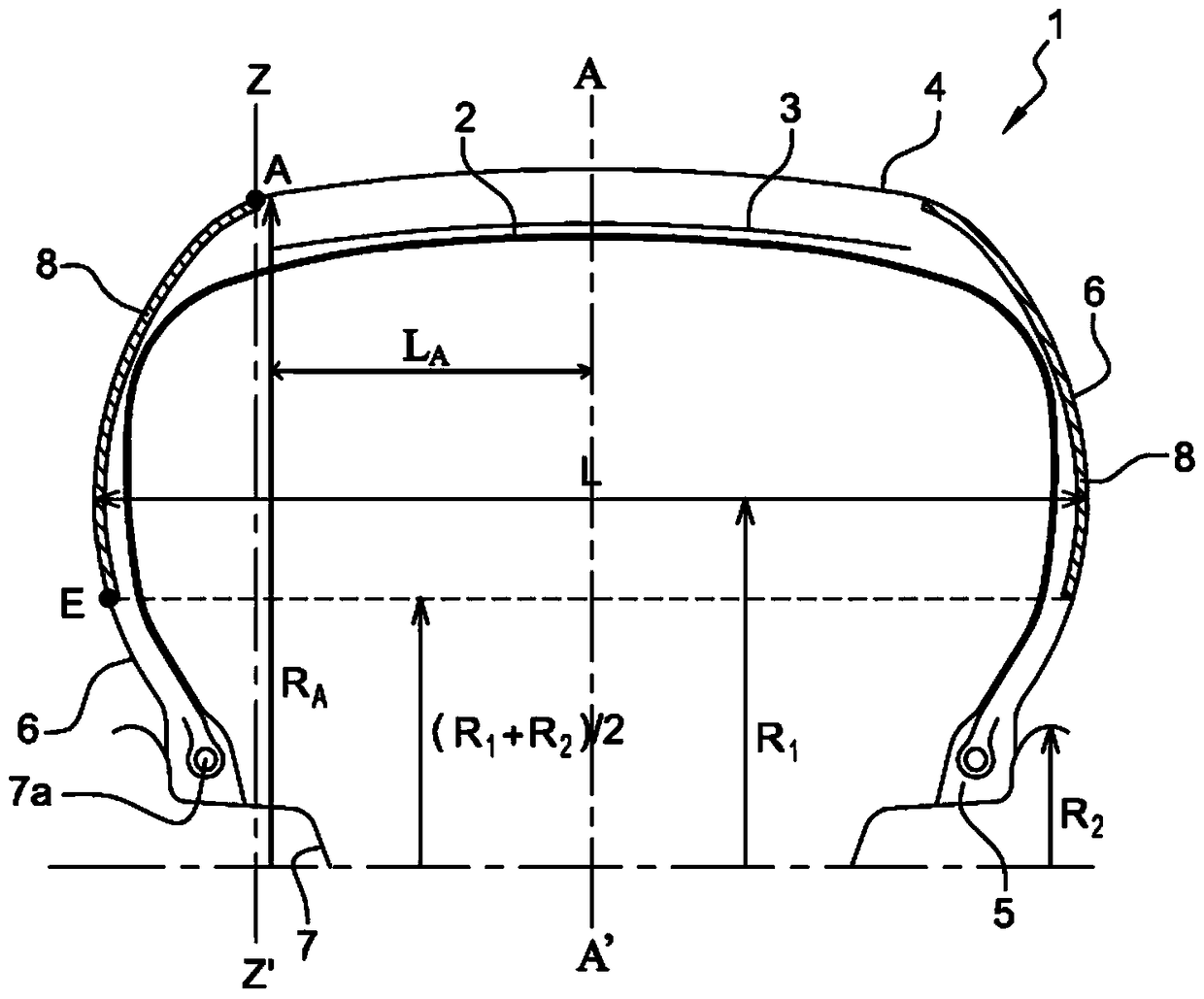

A technology for tires and rims, applied in tire parts, tire rims, reinforcement layers of pneumatic tires, etc., can solve problems such as damage to tires, sidewall collision and wear, etc., and achieve the effect of easy production, rapid production and production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] Example 1: Curb Test

[0097] The test was performed using a 205 / 55R16 reference tire including various protrusions and the same control tire without protrusions.

[0098] Tires P1 to P4 are respective tires according to the present invention.

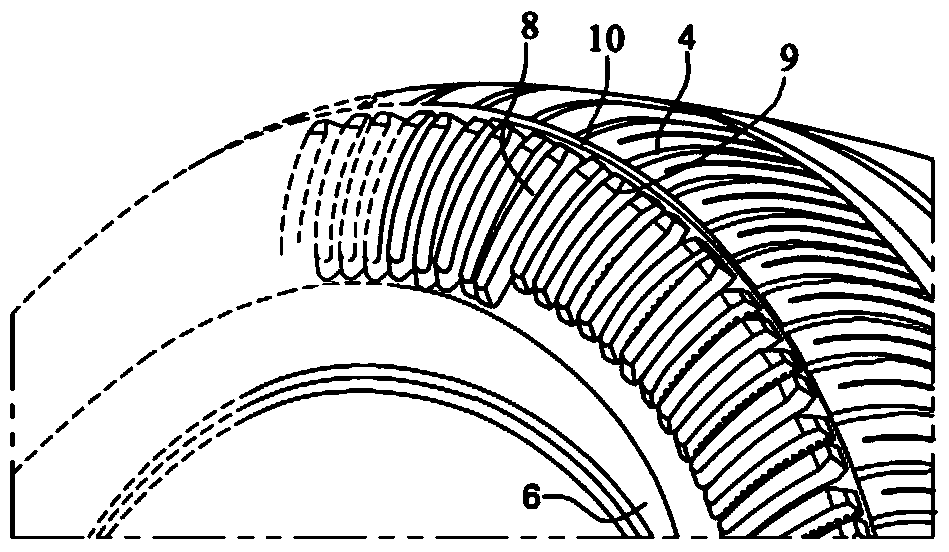

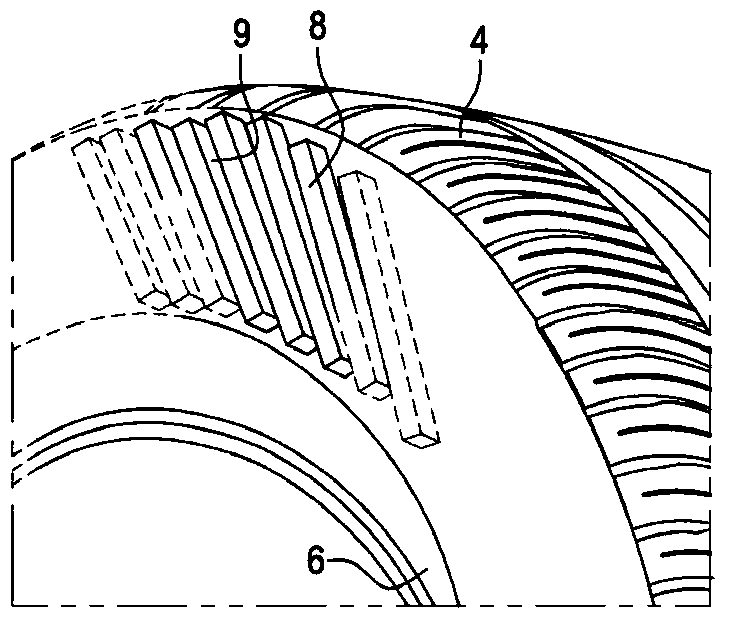

[0099] The protrusions of the tires P1 and P4 are arranged at a zero inclination angle with respect to the radial direction.

[0100] The protrusions of the tires P2 and P3 are arranged at a certain oblique angle with respect to the radial direction.

[0101] The column "angle" corresponds to the angle formed by each protrusion with the radial direction of the tire.

[0102] The relief angle α is the angle formed by each end of the protrusion (eg Figure 4 shown in ), designed to make the protrusions easier to release from the mold.

[0103] The interval of the protrusions is the distance between the center of the first void and the center of the second void adjacent to the first void.

[0104] H (mm) is the average heigh...

Embodiment 2

[0118] Example 2: Curb Test

[0119] The test was performed using a 245 / 40R18 reference tire including various protrusions and the same control tire without protrusions.

[0120] Tires P1 to P4 are various tires according to the present invention.

[0121] The various technical features mentioned with respect to Embodiment 1 are reproduced in Embodiment 2.

[0122] Table III below collects the measurable technical characteristics of the individual tires according to a variant of the invention.

[0123] Table III

[0124]

[0125]

[0126] The test was carried out under the same operating conditions as explained for Example 1 with an 8.5J 18 rim and a tire inflated to a pressure of 2.3 bar, mounted on the right front axle of the vehicle and supporting a load of 580 kg.

[0127] The results in Table IV below show that, before the punctures of the tires, an increase in speed was obtained between the control tire (result equal to 100) and the respective tires accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com