Correction in slit-scanning phase contrast imaging

一种相位衬度成像、狭缝扫描的技术,应用在成像装置、用于放射诊断的仪器、使用辐射衍射的材料分析等方向,能够解决条纹轮廓不像等问题,达到增强图像质量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

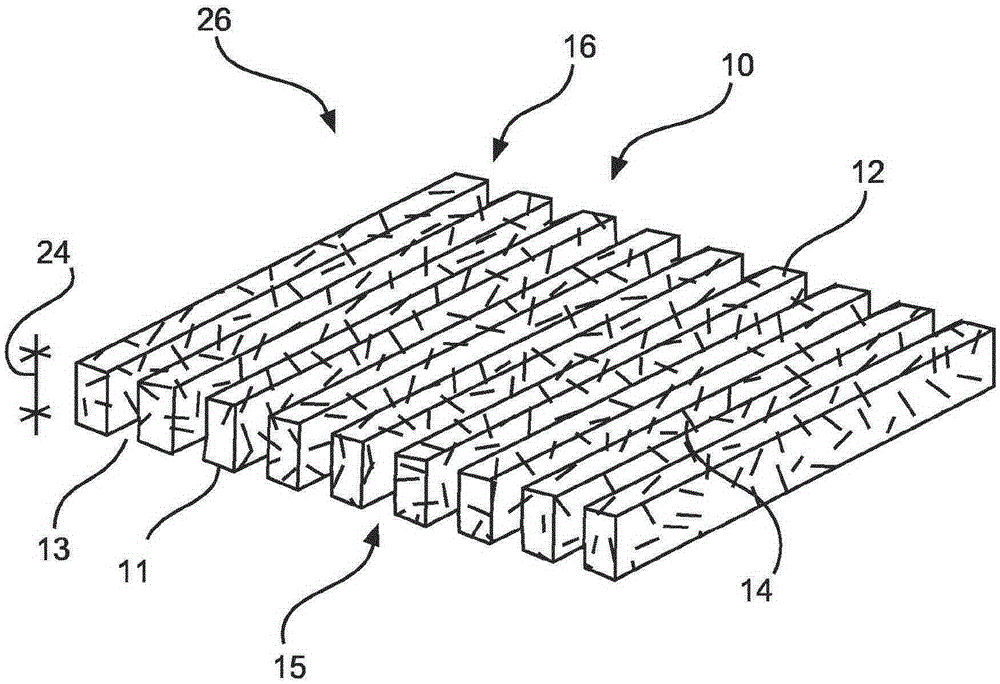

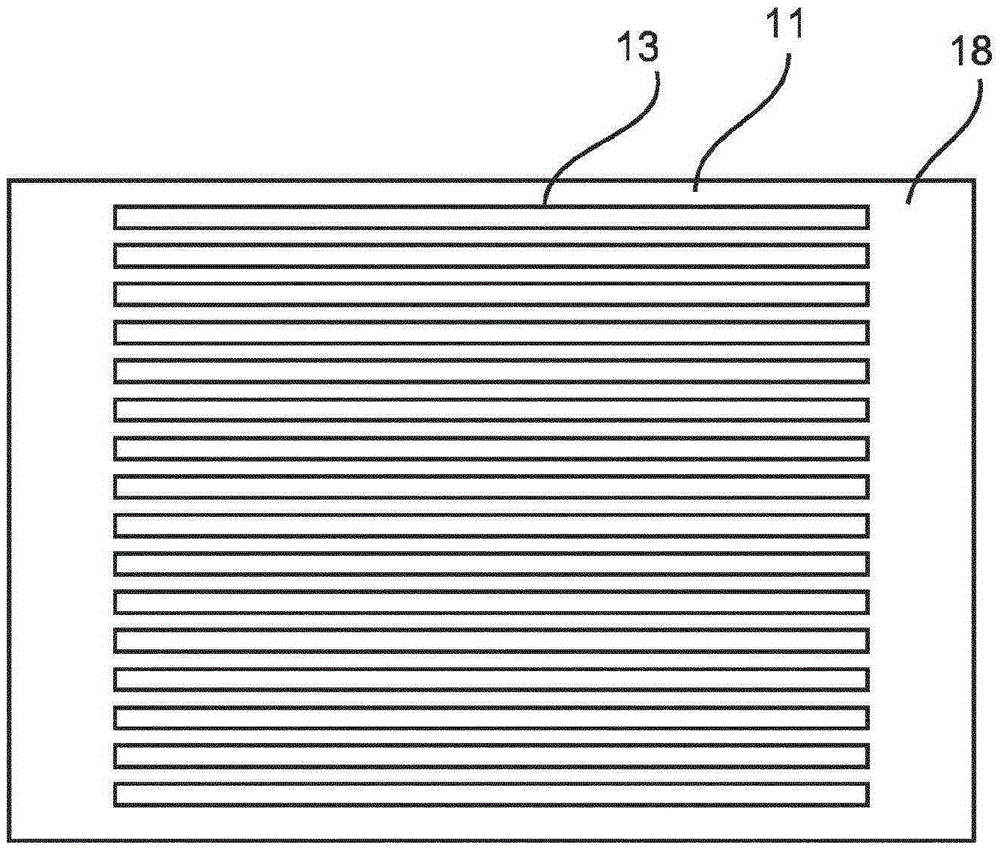

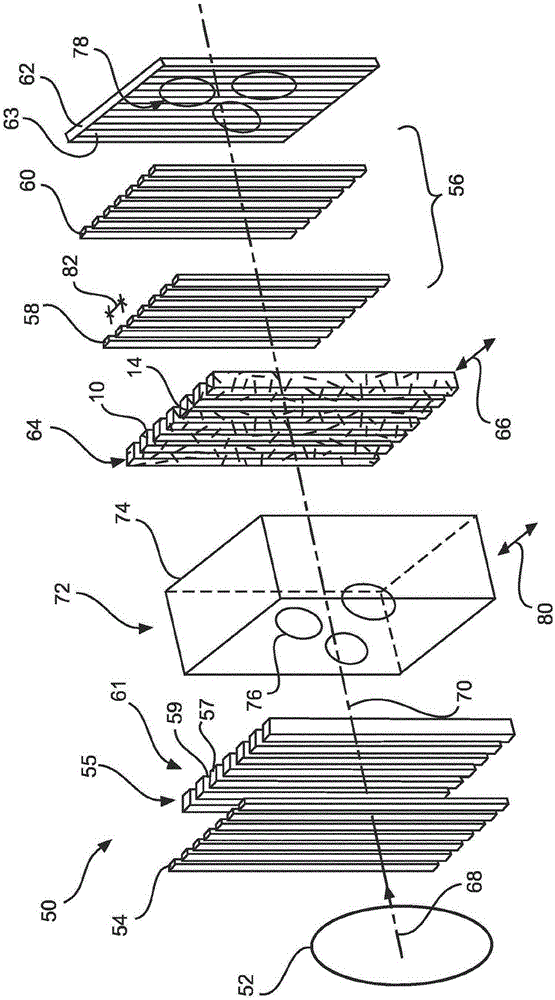

[0073] Figure 1A shows a calibration filter grating 10 for an X-ray phase contrast imaging device. The calibration filter grating 10 comprises a first plurality of filter segments 11 comprising filter material 12 . The filter material 12 is made of a material with structural elements 14 , which are only schematically shown in FIG. 1A , not to scale, comprising structural parameters on the order of micrometers. Furthermore, a second plurality of opening segments 13 is provided. Filter segments 11 and opening segments 13 are arranged alternately in a filter pattern 15 . The calibration filter grating 10 is configured to be movably arranged between the X-ray source grating and the analysis grating of the interferometer unit in the slit scanning system of the phase contrast imaging device, which will also be relative to Figure 2 to Figure 6 It will be described in more detail. The filter pattern 15 is configured to align with the slit pattern of the slit scanning system (see a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com