Centrifugal fan impeller capable of adjusting splitting vanes

A centrifugal fan and splitter blade technology, which is applied to the components of pumping devices for elastic fluid, mechanical equipment, machines/engines, etc. Fan operation stability problems, etc., to achieve the effect of improving the secondary flow phenomenon, meeting the needs of energy saving and comfort, and improving the working ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

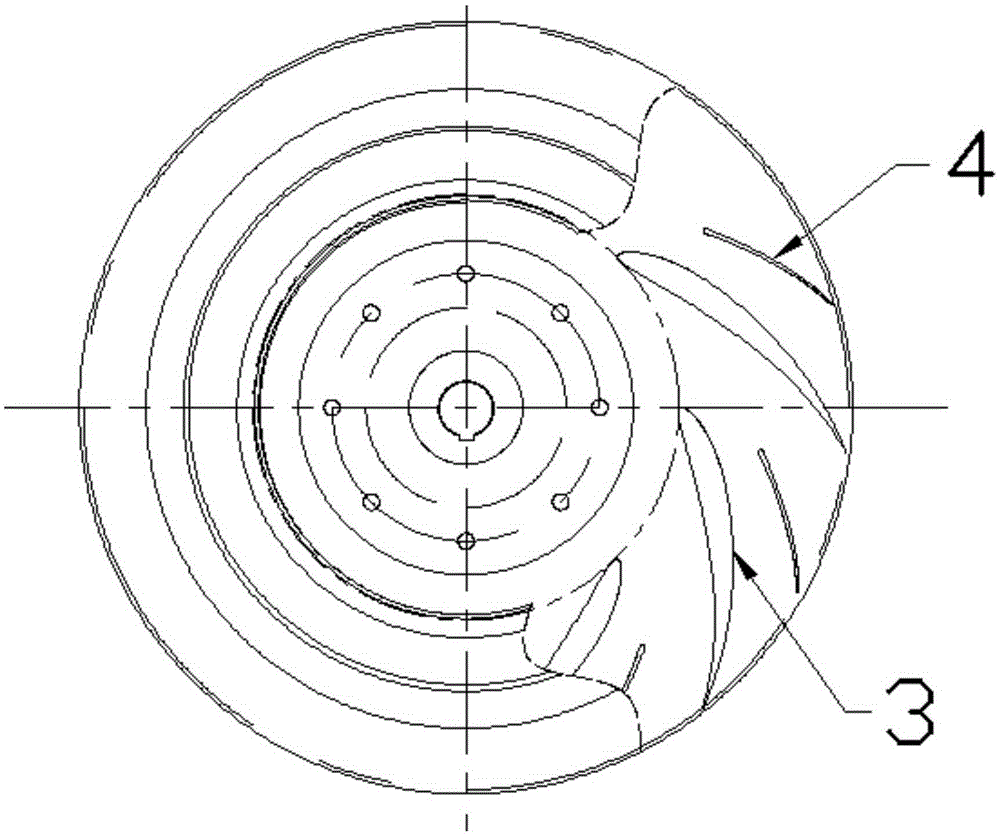

[0025] like figure 1 and 2 As shown, a centrifugal fan impeller with adjustable splitter blades includes a wheel disc 1 , a wheel cover 2 , main blades 3 , splitter blades 4 and a splitter blade adjustment device 5 . Between the wheel disc 1 and the wheel cover 2, n pieces of main blades 3 uniformly distributed along the circumference are fixedly arranged, n≥8; a splitter blade 4 is arranged between every two adjacent main blades 3; the splitter blade adjustment device 5 is used to adjust the splitter flow Blades 4 angles.

[0026] like image 3 As shown, the splitter vane adjusting device 5 includes a total fixed frame 5-1, a guide ring 5-2, a fixing device 5-3 on the splitter vane ring, a splitter vane adjustment member 5-4, and a fixing device 5 on the splitter vane wheel cover. -5 and the fixing device 5-6 on the splitter blade disc. The guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com