Rotary type tire grabbing device of tire shaping and vulcanizing machine

A stereotyped vulcanization and rotary technology, applied in the field of tire vulcanizing machine component structure, can solve the problem of unfavorable smoothness and moderate problems, and achieve the effect of eliminating the influence and improving the vulcanization quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

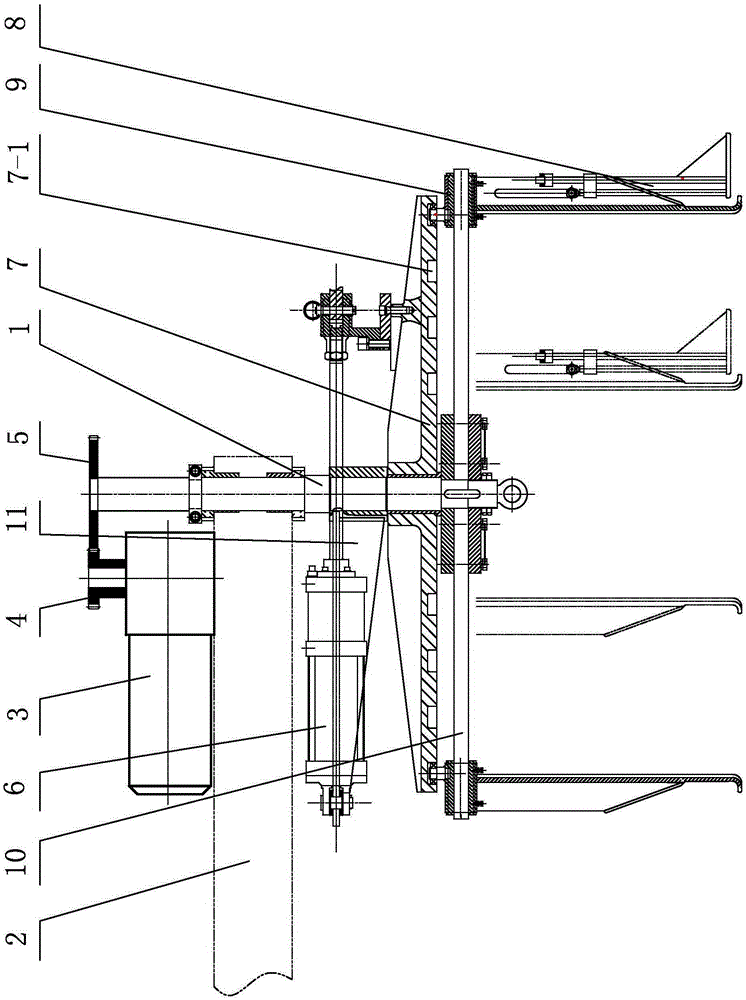

[0017] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0018] The rotary tire gripper of the tire shaping and vulcanizing machine of the present invention includes a tire gripping device, and the tire gripping device is installed on the rotating shaft 1, and the rotating shaft 1 is installed on the rotating arm 2 of the tire gripping manipulator, and the rotating arm 2 A transmission device is provided to drive the rotation of the tire gripping device. Driven by the transmission device, the tire gripping device can rotate as a whole to adapt to the centering when releasing the raw tire (especially when the steel ring of the large-sized raw tire is deformed) ),Such as figure 1 , figure 2 shown.

[0019] The rotating shaft 1 is installed vertically through the shaft sleeve provided inside the rotating arm 2 on the rotating arm 2. The transmission device includes a rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com