Clamping and forced conveying mechanism at the discharge end of saw based on vertical axis split

A technology of conveying mechanism and split saw, which is applied to circular saws, unloading equipment, manufacturing tools, etc. It can solve the problems of product quality reduction, material breaking, and material jamming, and achieves improved production efficiency, wide application range, and surface quality. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

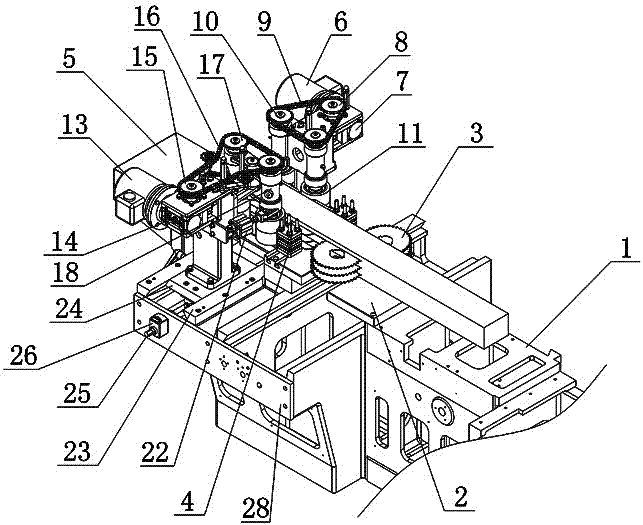

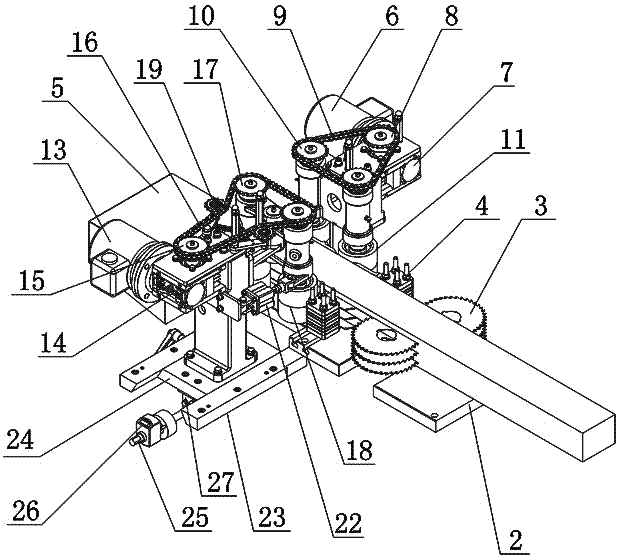

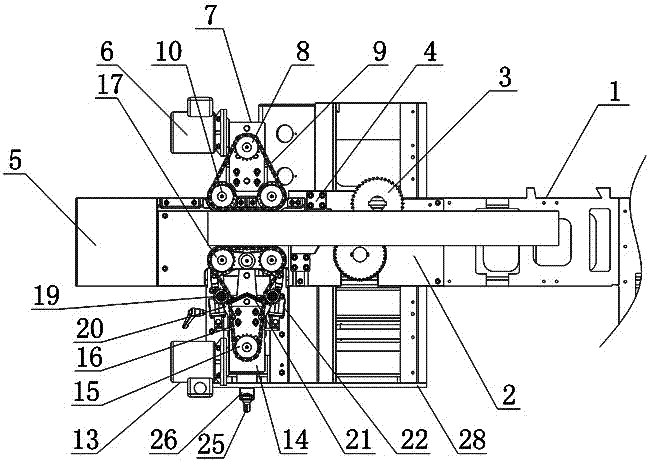

[0022] Such as figure 1 As shown, the clamping and forced conveying mechanism at the discharge end of the saw based on the split vertical axis includes a machine base 1, a workbench 2 fixed above the machine base 1, a saw blade 3, a fixed-side conveying assembly, a swinging-side conveying assembly, and a swinging assembly. The machine base 1 is made of high-quality castings. After special heat treatment and precision machining, the stability of the machine base 1 is enhanced and its precision is improved. The saw blade 3 is installed above the workbench 2 through the rotation of the saw shaft. The saw shaft is driven by the saw motor to rotate. The blade 3 is directly installed on the saw shaft, which can reduce the diameter of the saw blade 3, so that thin saw blade processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com