A specimen pressurizing device for three-dimensional photoelastic stress experiment

A pressurizing device and photoelastic technology, applied in the field of specimen pressurizing devices, can solve the problems of inconvenient movement, the inability of the pressurizing device to display the magnitude of the loading force, and the inability of the oven to bear the weight of excessive weights, so as to prolong the service life, The effect of large load value and accurate digital display of load value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

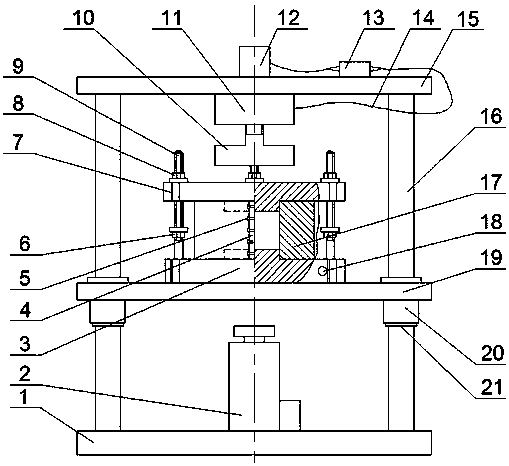

[0028] A specimen pressurizing device for three-dimensional photoelastic stress experiment. Such as figure 1 with figure 2 As shown, the specimen pressurization device for three-dimensional photoelastic stress experiment consists of three parts: loading device, pressure holding device and pressure measuring device.

[0029] Such as figure 1 with figure 2 As shown, the structure of the loading device is: a jack 2 is fixed at the middle position of the bottom plate 1, guide rods 16 are symmetrically fixed at four corners of the bottom plate 1, and ring-shaped bosses 21 are provided on the four guide rods 16 at equal heights; The four corners of 19 are fixed with sliding sleeves 20, and the four sliding sleeves 20 are looped on the corresponding guide rods 16. The sliding plate 19 is located on the annular boss 21. The height of the lower plane of the sliding plate 19 is 1.05 of the height of the initial position of the jack 2. ~1.10 times, the upper ends of the four guide ...

Embodiment 2

[0037] A specimen pressurizing device for three-dimensional photoelastic stress experiment. Except following technical parameter, all the other are with embodiment 1:

[0038] The height of the lower plane of the slide plate 19 is 1.10 to 1.15 times the height at the initial position of the jack 2;

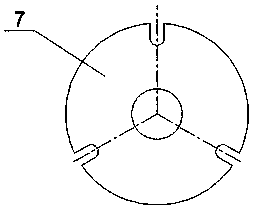

[0039] The die 17 is composed of two identical semi-cylinders, the outer walls of the four sides of the two semi-cylinders are respectively provided with ear plates 4, and the four sides are parallel to the axis of the semi-cylinders, and each ear plate 4 is symmetrically Screw holes are provided, and there are 4 screw holes. The bolt 5 connects the two half cylinders as a whole through the screw holes, and the wall thickness of the half cylinders is 35-50 mm.

[0040] Compared with the prior art, this specific embodiment has the following positive effects:

[0041] In this specific embodiment, the radial constraint is provided to the test piece through the die 17 , and the axia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com