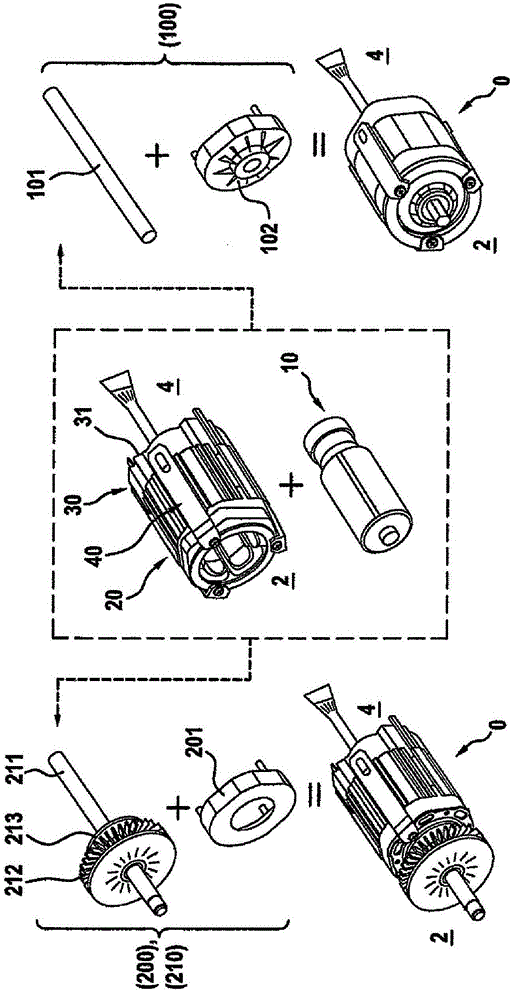

Electric motor construction kit and electric motor

A technology of combined components and motors, applied in the direction of electric components, magnetic circuit rotating parts, electrical components, etc., can solve problems such as application restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

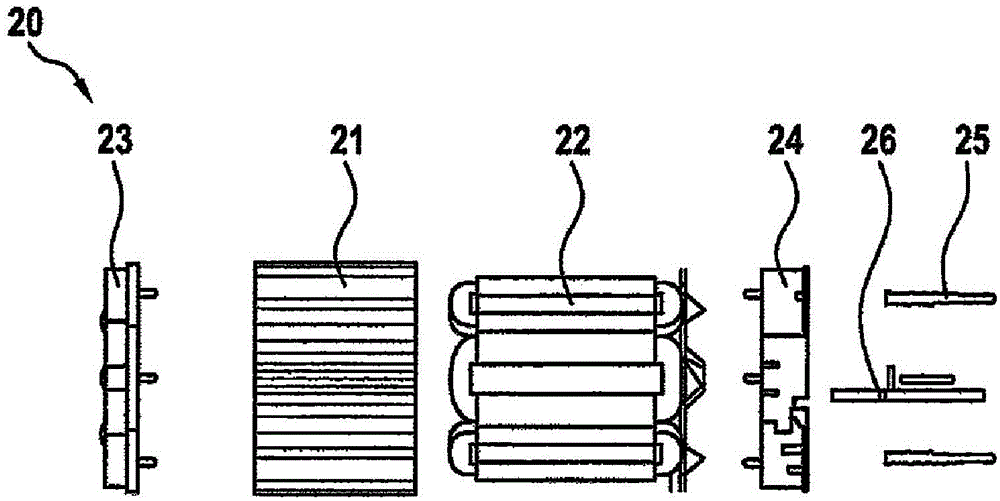

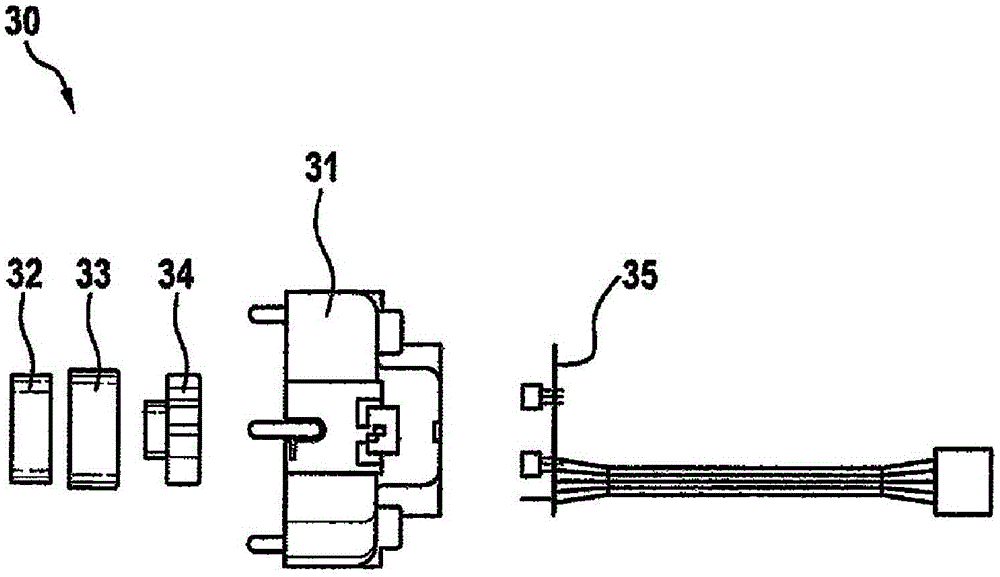

Embodiment Construction

[0041] By means of a fixed definition of the construction of the motor as either a fully supported motor (full case construction) or an open frame motor (open frame solution) and a fixed definition of the conduction of the air flow at or through the motor , apply the same motor to meet different requirements, eg limited in different tool types. This means that a dedicated motor must be used for each tool type. For example, in the case of product applications in (strongly) polluted environments (conductive dust, magnetic dust, e.g. on angle handle hand grinders), it is necessary or at least advantageous to use enclosed electric motors (also called enclosed motors) of.

[0042] Only relatively low powers of such electric motors can be achieved with some possible solutions for cooling such canned motors. If the same motor were applied to a product used in a less polluted environment (such as a hole saw), then only lower power could be achieved here, although the same motor with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com