A usb Type‑C connector

An integrated, connecting part technology, applied in the field of USB connectors, can solve the problems of short service life of USB Type-C connectors, thick USB Type-C connectors, single shape of shielding shell, etc., achieve rich and beautiful appearance, reduce assembly processes, and improve resistance The effect of the ability to jam the signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

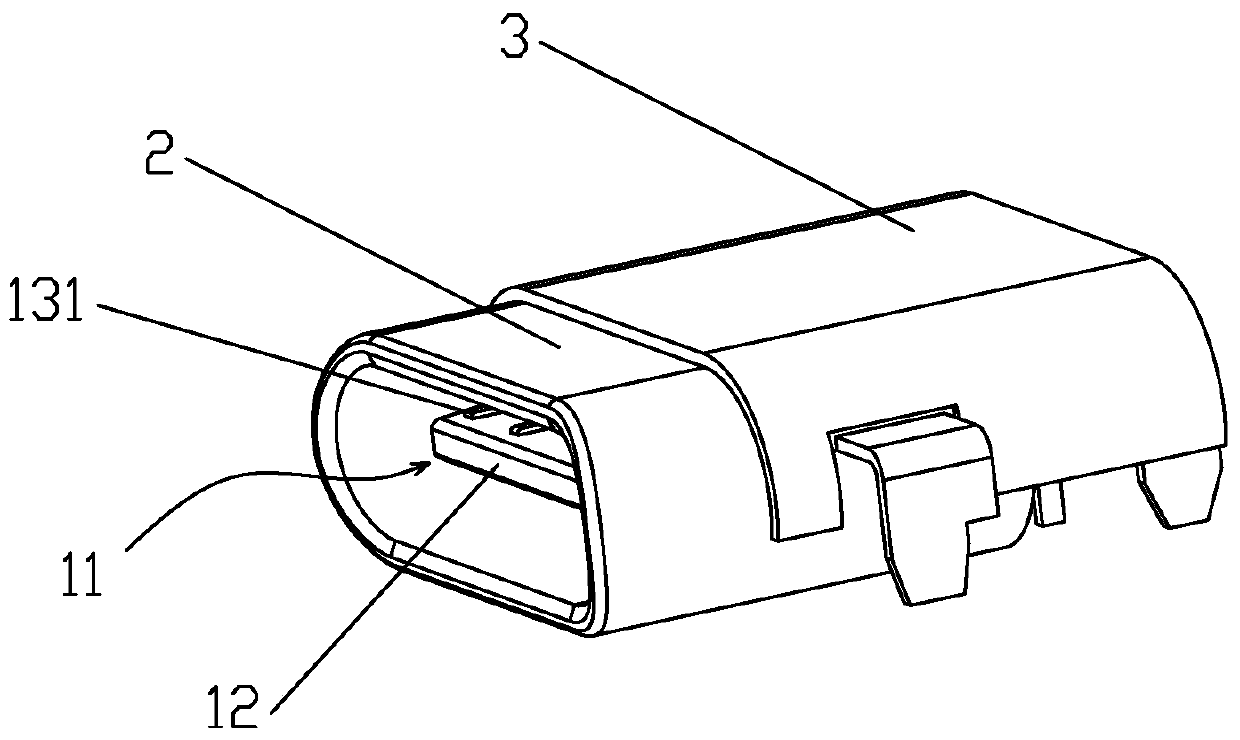

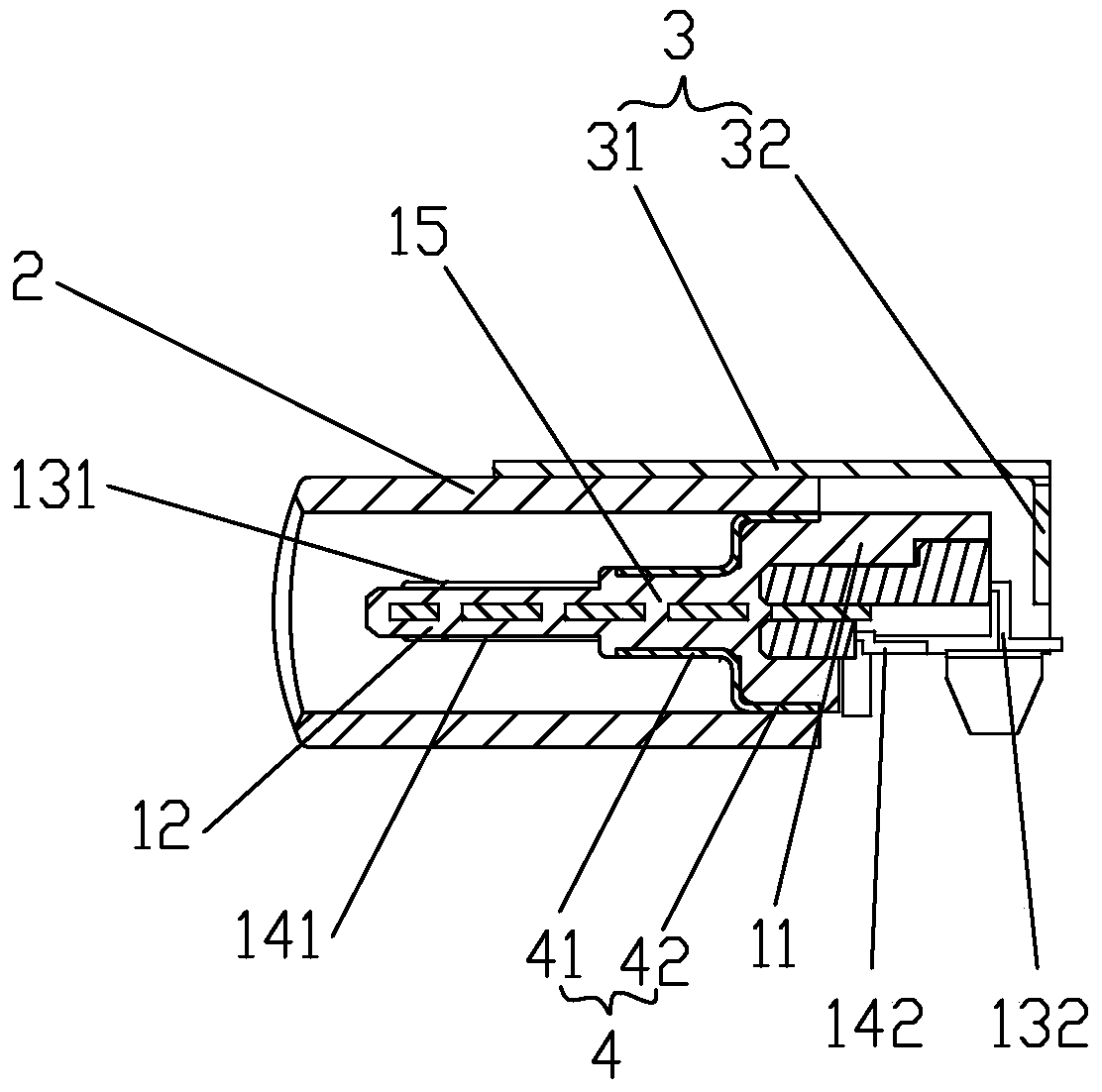

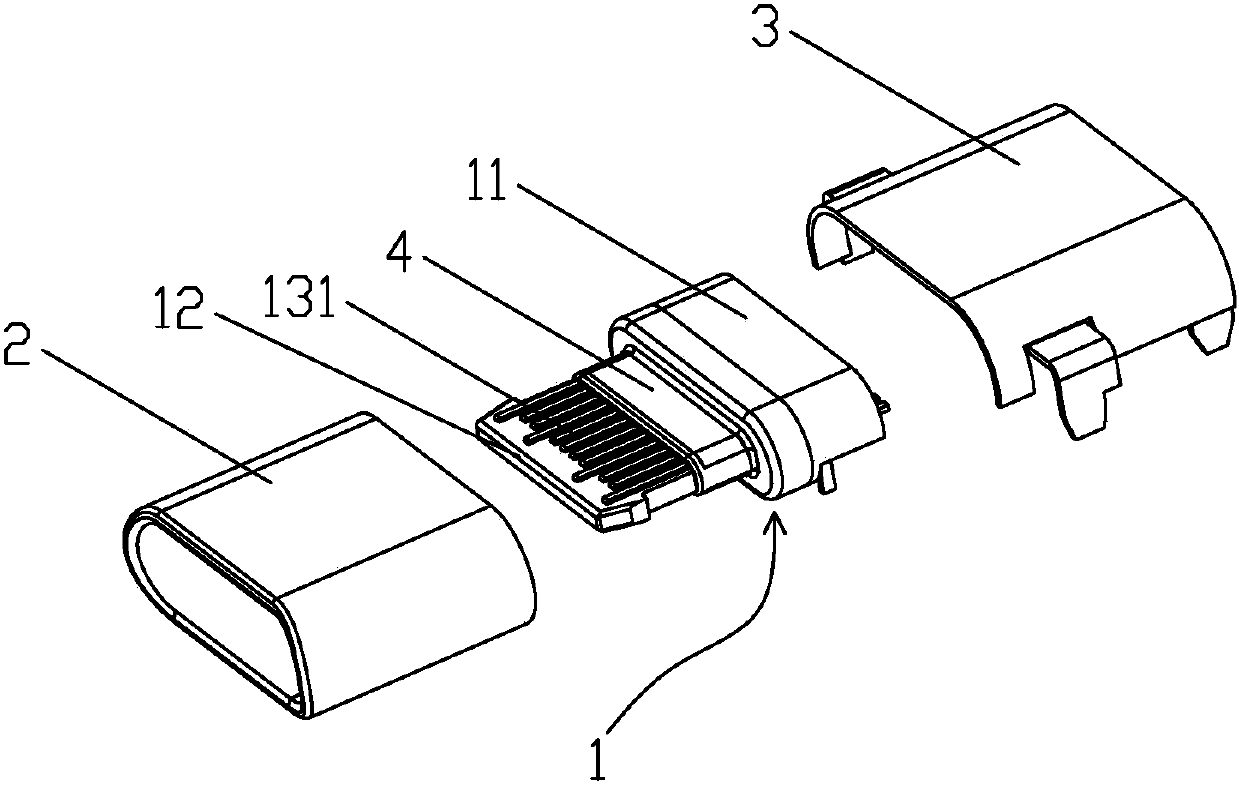

[0024] Such as figure 1 , figure 2 and Figure 5 As shown, a USB Type-C connector includes a terminal assembly 1. The terminal assembly 1 includes an insulating seat body 11, and the insulating seat body 11 is provided with a tongue plate 12 integrally formed with it and protruding forward. , the insulating base 11 is provided with an upper row of PIN needles 13 and a lower row of PIN needles 14 that are injection molded into one body and separated from each other. The upper row of PIN needles 13 includes an upper The front part 131 of the row of PIN needles and the rear part 132 of the upper row of PIN needles exposed on the insulating seat body 11, the described lower row of PIN needles 14 includes the front part 141 of the lower row of PIN needles exposed on the lower side of the tongue plate 12 and the rear part of the row of PIN needles exposed on the insulating sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com