Workpiece stopping device

A technology for stopping devices and workpieces, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as scratches and insufficient shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

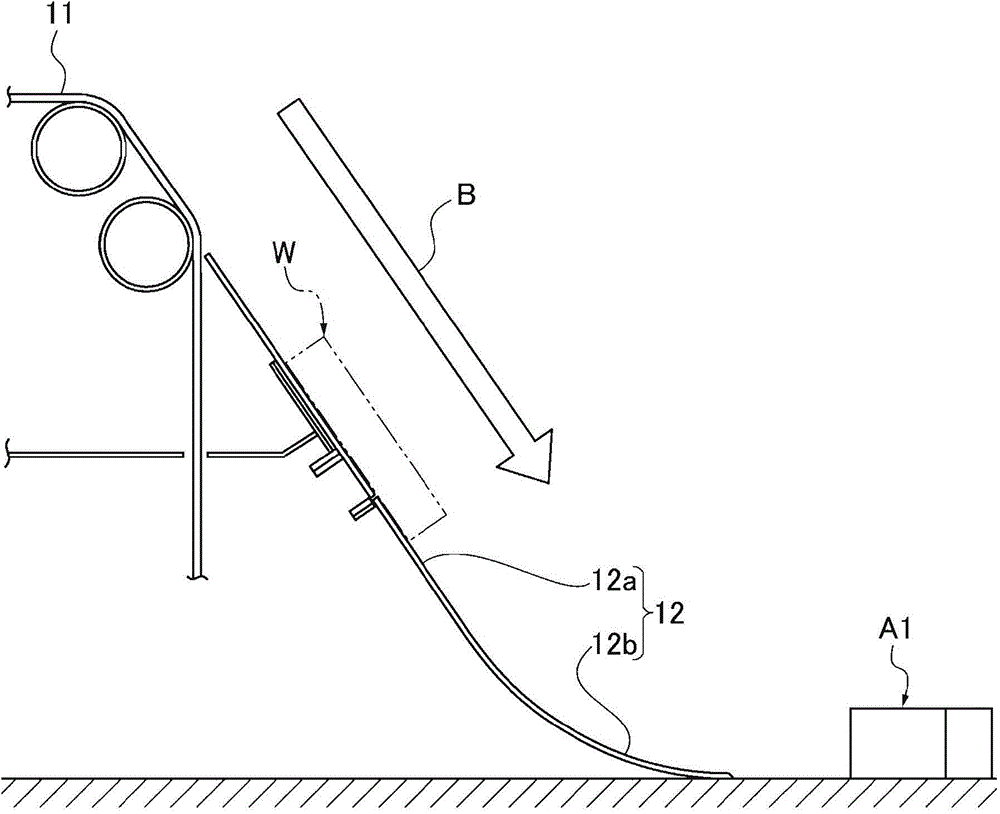

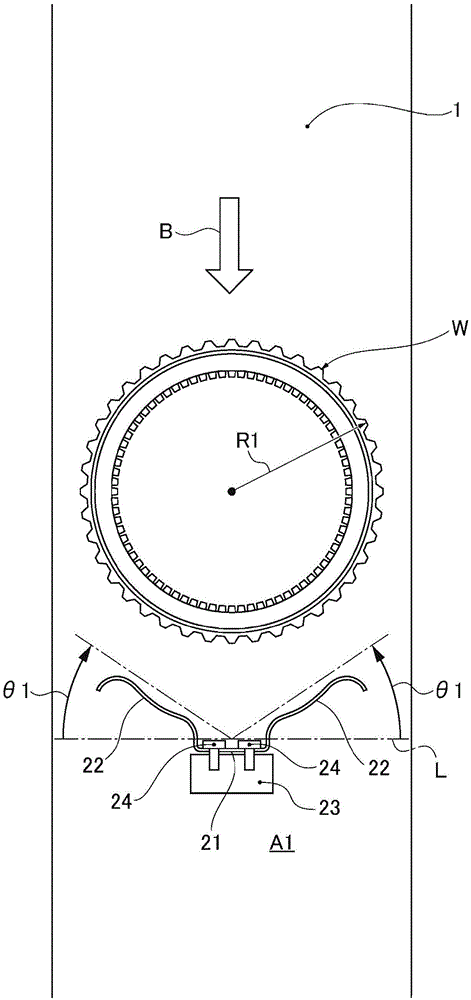

[0040] First, based on figure 1 The configuration of a gear production line for an automatic transmission to which the work stopper device A1 of the first embodiment is applied will be described.

[0041] In the gear manufacturing line of automatic transmission, such as figure 1 As shown, a gear member W (an example of a circular workpiece) immediately after being heated in a furnace for heat treatment is conveyed by falling down the chute of the workpiece conveyance path 1 based on the conveyor belt 11 and the slide plate 12 . The setting angle of the workpiece conveying path 1 formed by the conveying belt 11 and the straight path 12a of the slide plate 12 is formed at a steep angle of more than 55 degrees, for example, with little space. The slide plate 12 has a curved path 12b continuous with the straight path 12a, and the horizontal end position of the curved path 12b is set as a workpiece stop position.

[0042] The workpiece stopper A1 is arranged at the workpiece stop...

Embodiment 2

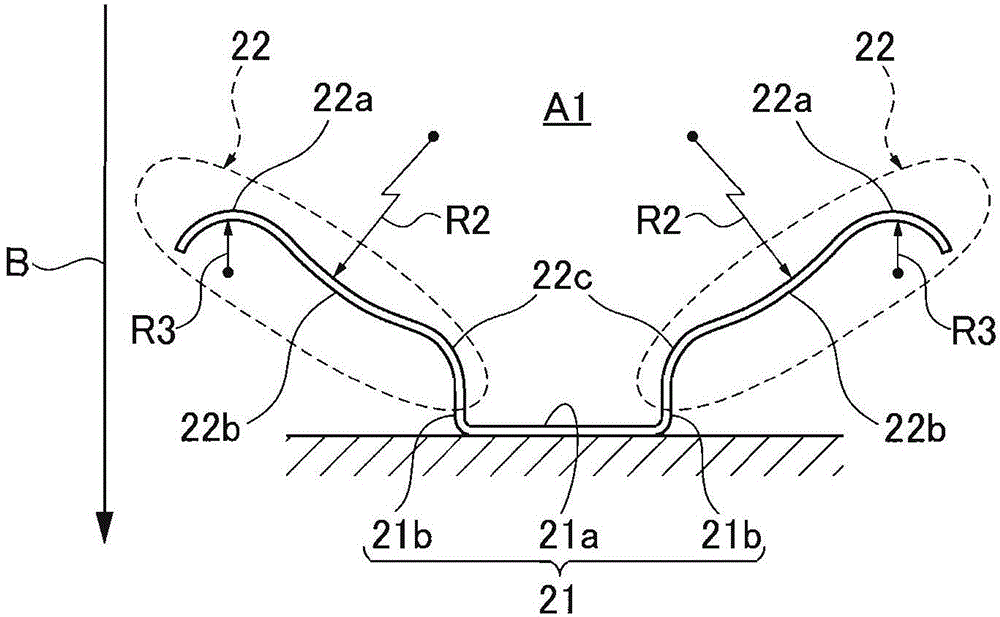

[0063] Embodiment 2 is a modified example in which the shapes of the pair of extensions 22 and 22 are different from those of Embodiment 1. As shown in FIG.

[0064] based on Figure 4 The structure of the pair of extension parts 22 and 22 in the work stopper A2 of Example 2 is demonstrated.

[0065] The pair of extensions 22 and 22 of the second embodiment extend in a substantially V-shape in the oblique direction from both sides of the base 21 fixed to the block 23 , and contact the gear member W to stop it. The inclination angles θ2 and θ2 of the pair of extensions 22 and 22 are formed to be angles that act 60 degrees from both sides of the line L in the direction perpendicular to the workpiece conveyance direction B to the travel direction B of the component. That is, the opening angle of the V shape of the blocker gear member W is set to about 60 degrees.

[0066] The pair of extension parts 22, 22 has first curved parts 22a', 22a' on the outer side of the part where th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com