An inspection robot telescopic arm

An inspection robot and telescopic arm technology, applied in the field of robots, can solve the problems of complex application scenarios, difficult product miniaturization and cost control, and achieve the effects of stable and reliable structure, simple and reliable driving, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

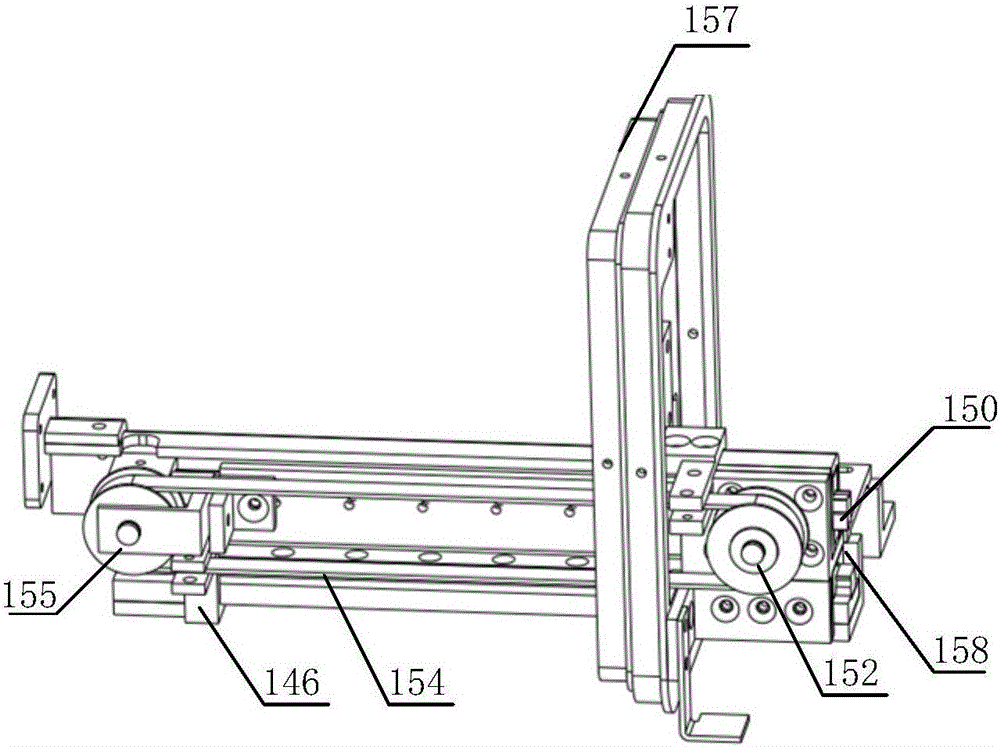

[0022] Such as figure 1 As shown, the detection system of the inspection robot is composed of a mobile sensor system 101, a hanging arm 102, and a detection box 103; The body moves up and down; the detection box 103 is provided with three layers of sensor installation points from top to bottom, respectively, such as infrared, visible light cameras, ultrasonic sensors, etc., where the bottom layer is the installation point of the mobile sensor system 101, and the sensors are installed on the inspection robot. On the telescopic arm, the sensor and the telescopic arm of the inspection robot jointly constitute a mobile sensor system 101. When the robot arm is telescopic, the sensor can adjust the detection position forward and backward; the first and second layer sensors of the detection box 103 are fixed relative to the detection box body itself. The telescopic arm of the inspection robot provided is installed at the installation point of the mobile sensor 101 .

[0023] Such as...

Embodiment 2

[0030] In combination with Embodiment 1, in order to further enhance the telescopic distance, the telescopic arm of the inspection robot provided by the present invention adopts a multi-stage telescopic arm, and the structure of the telescopic arm at each level is the same as that of the middle telescopic arm. The belt 141 is connected, and the slider of the first-stage telescopic arm is sleeved on the base rail 144 and can slide on the base rail; the guide rail of the second-stage telescopic arm is connected with the belt of the first-stage telescopic arm, and the sliding block of the second-stage telescopic arm The block is set on the guide rail of the first-stage telescopic arm and can slide on the guide rail of the first-stage telescopic arm; and so on, the guide rail of the last-stage telescopic arm is connected with the belt of the penultimate telescopic arm, and the last-stage telescopic arm The slider of the arm is set on the guide rail of the penultimate telescopic arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com