Rotating support of rotary platform

A technology of slewing bearings and rotating platforms, which is applied in metal processing and other directions, and can solve the problems of low precision of slewing bearings, rotation deviation and restrictions of slewing bearings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

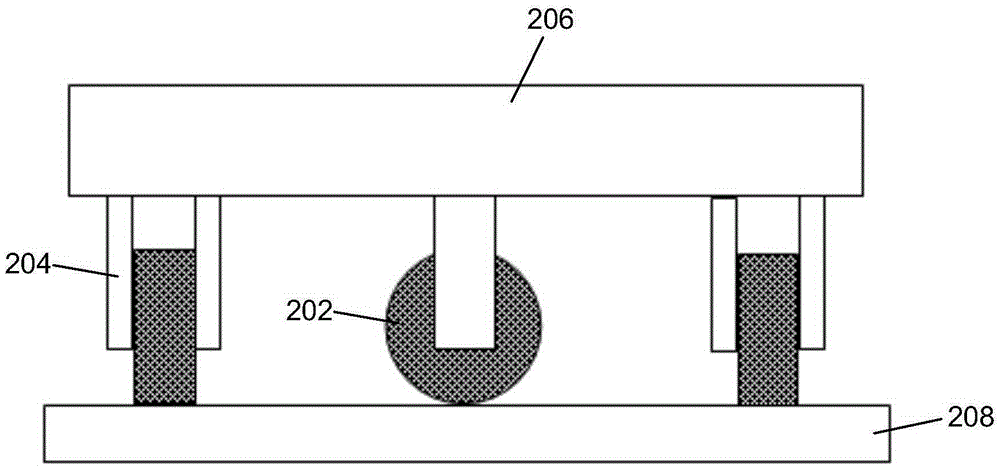

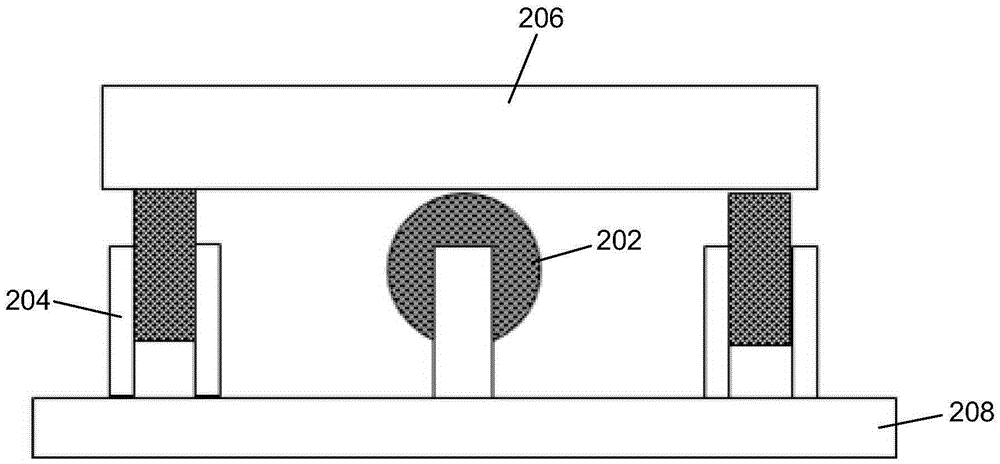

[0025] The present invention aims to propose a slewing bearing, which includes an upper raceway surface, a lower raceway surface and a roller mechanism installed between the upper raceway surface and the lower raceway surface, and the roller mechanism is opposite to the upper raceway surface and the lower raceway surface. Surface rolling causes the upper raceway surface to swivel relative to the lower raceway surface, where the rolling path of the roller mechanism is constrained. Specifically, the present invention installs the upper raceway surface, the lower raceway surface and the roller mechanism on a central shaft, and the rolling path of the roller mechanism is limited by the central shaft. The slewing bearing of the present invention has small resistance and is a fully rolling slewing bearing. After the slewing bearing of the present invention is applied to the rotary platform, the rotary resistance of the rotary platform can be greatly reduced, the rotation is stable, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com