Stack-up connecting element, connector and connector group

A connector group and connector technology, applied in the direction of instruments, optical components, light guides, etc., can solve the problems of increased production cost, troublesome operation, poor versatility, etc., and achieve the effect of good versatility, convenient assembly, and easy assembly and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

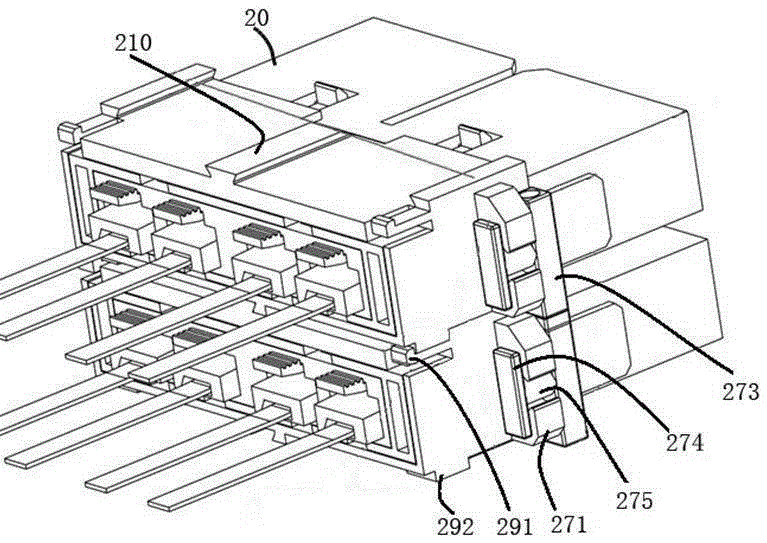

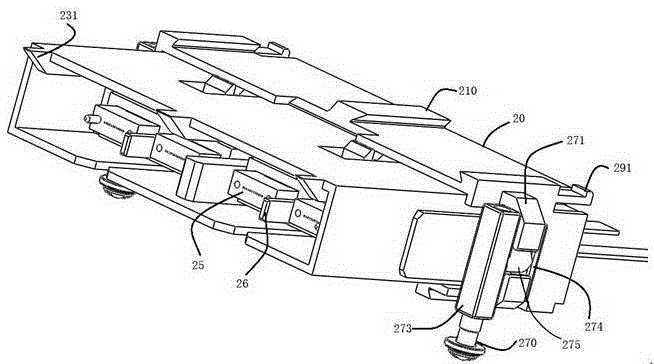

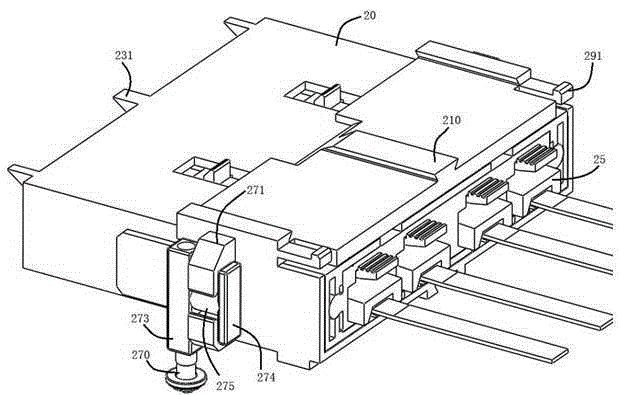

[0025] Embodiment 1 of the connector set of the present invention: as figure 1 As shown, it includes two connectors stacked up and down. In this embodiment, for the sake of illustration, only two connectors are stacked as an example. In other embodiments, the number of connectors can be three or three above. The structure of the connector is as Figure 2-9 As shown, it includes a rectangular connector housing 20 and a floating connection structure connecting the housing 20 and a fixed mounting plate. The stacking connector for fixing the mounting plate, the stacking connector includes a connecting column 273 extending up and down for connecting with the side of the connector housing 20, the upper end of the connecting column 273 is provided with an upper threaded hole 2732, the connecting column The lower end of the body is provided with a lower threaded hole 2731, and the connecting cylinder 273 connects the connector to the horizontal base plate through the screw connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com