Unit magnetic pole structure of permanent magnet motor rotor

A permanent magnet motor, magnetic pole structure technology, applied in the magnetic circuit shape/style/structure, magnetic circuit rotating parts, manufacturing stator/rotor body and other directions, can solve problems such as complex situations, achieve convenient operation, and enhance axial positioning and sealing, preventing tooth rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

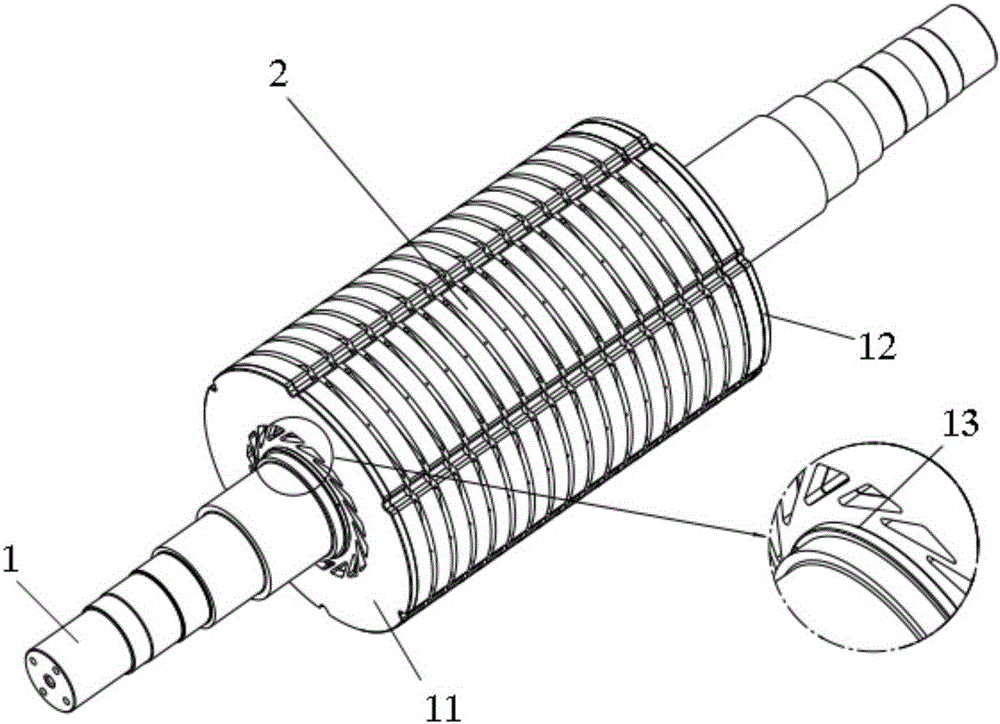

[0025] Such as figure 1 As shown, the unit magnetic pole structure of the permanent magnet motor rotor of the present invention mainly includes two parts of the rotating shaft 1 and the rotor core. The rotor core is divided into several unit poles 2 in the axial direction, and each unit pole 2 is manufactured separately and then fixed on the rotating shaft 1 . Radial ventilation slots are formed between adjacent unit poles 2 .

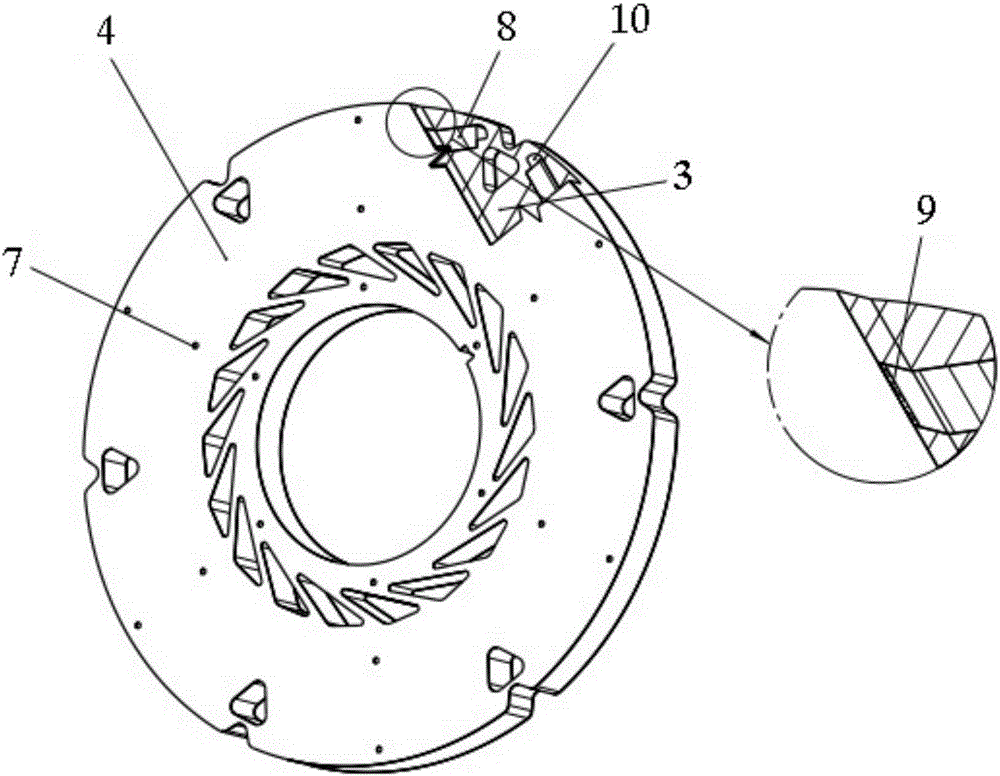

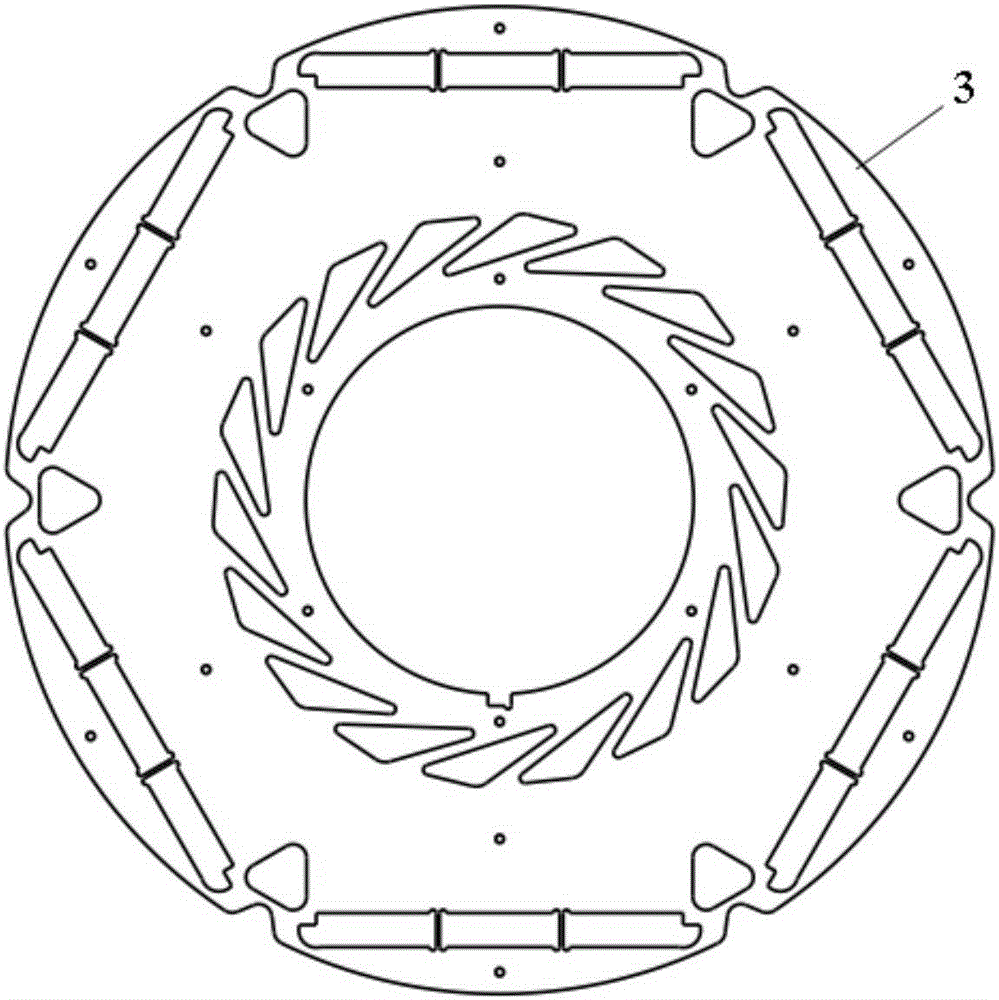

[0026] Such as figure 2 Shown is the structure of the unit pole 2. Each unit magnetic pole 2 is an independent rotor core, which is convenient for mass production and convenient for assembly. The composition of unit magnetic pole 2 includes rotor punching plate 3, iron core ventilation pressure plate 4, ventilation slot plate 5 (optional), ventilation slot piece 6 (optional), stainless steel rivet 7, magnetic st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com