Audio Module Bonding Detector

A detector and audio technology, applied in the direction of line/collector components, electrical components, circuits, etc., can solve the problems of inflexible operation, affecting work efficiency, increasing cost and weight, etc., and achieve convenient and fast operation , The effect of convenient tangent operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

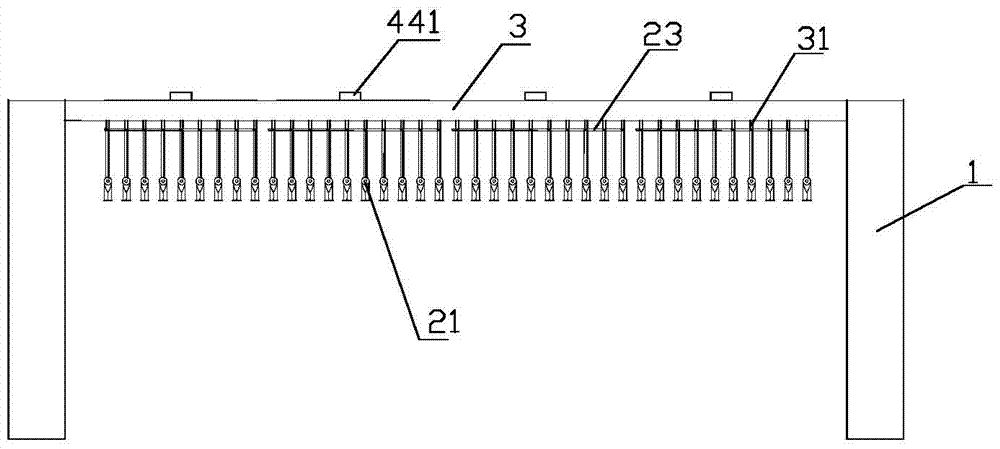

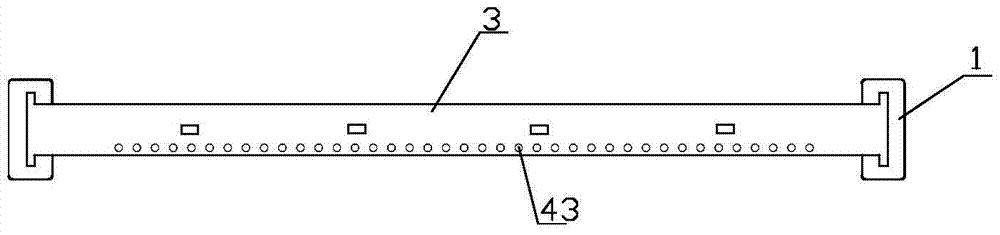

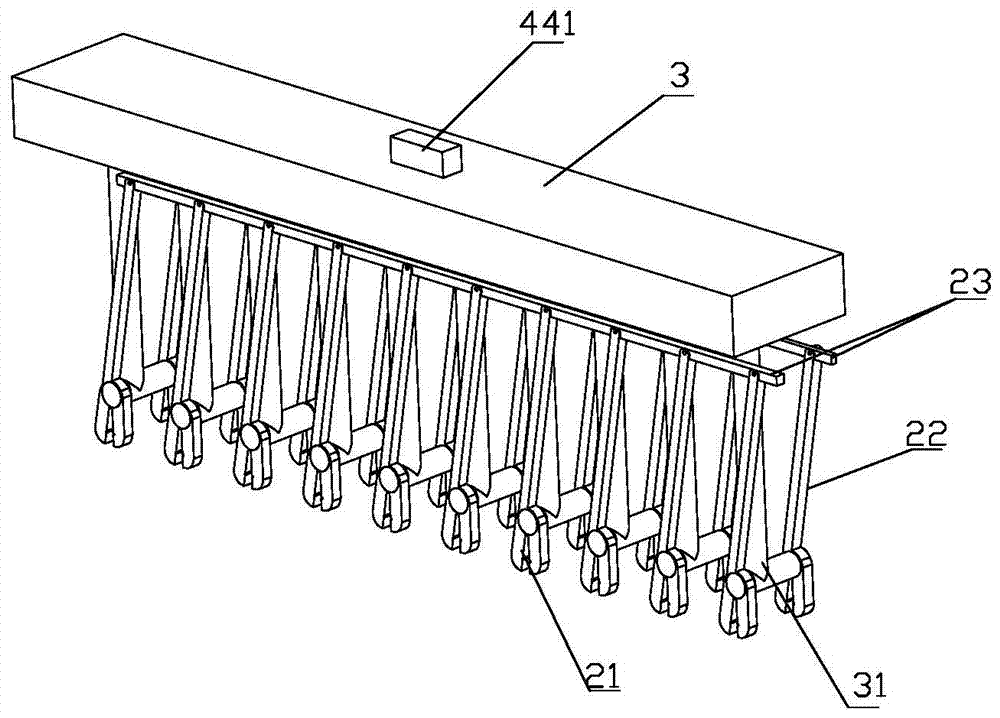

[0038] Such as Figure 1-Figure 10 As shown, the present invention includes a fixed frame 1, a first tensioner 2, a pressure block 3 and a detection device, the pressure block 3 is nested in the fixed frame 1, and the pressure block 3 can slide up and down in the fixed frame 1 , the detection device is arranged on the pressing block 3 . The inner side of the lower part of the fixed frame 1 is provided with engaging slots that cooperate with both sides of the audio module.

[0039] The first wire clamp 2 includes a wire clamp 21, a connecting rod 22 and a tie rod 23. The wire clamp 21 includes a pincer foot I 211 and a pincer foot II 212, which are oppositely arranged on the pincer foot I 211 and pincer foot II 212. There is a clamping groove 213. Preferably, after the clamp foot I 211 and the clamp foot II 212 are docked, the clamping groove on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com