An intelligent weeder and weed removal method thereof

A weeder and intelligent technology, applied in the field of agricultural machinery, can solve problems such as damage to crops, non-compliance, and droplet drift of spray equipment, and achieve the effects of improving real-time performance, improving accuracy, and reducing computational workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

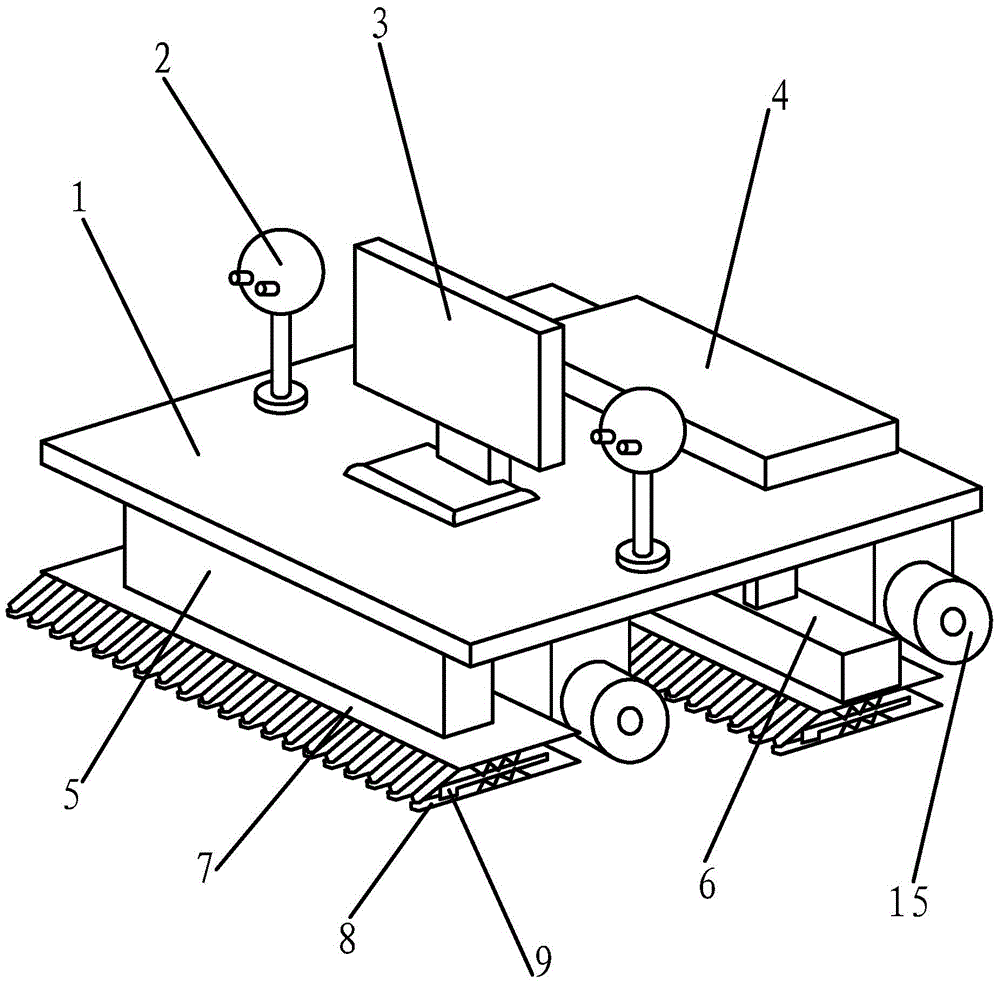

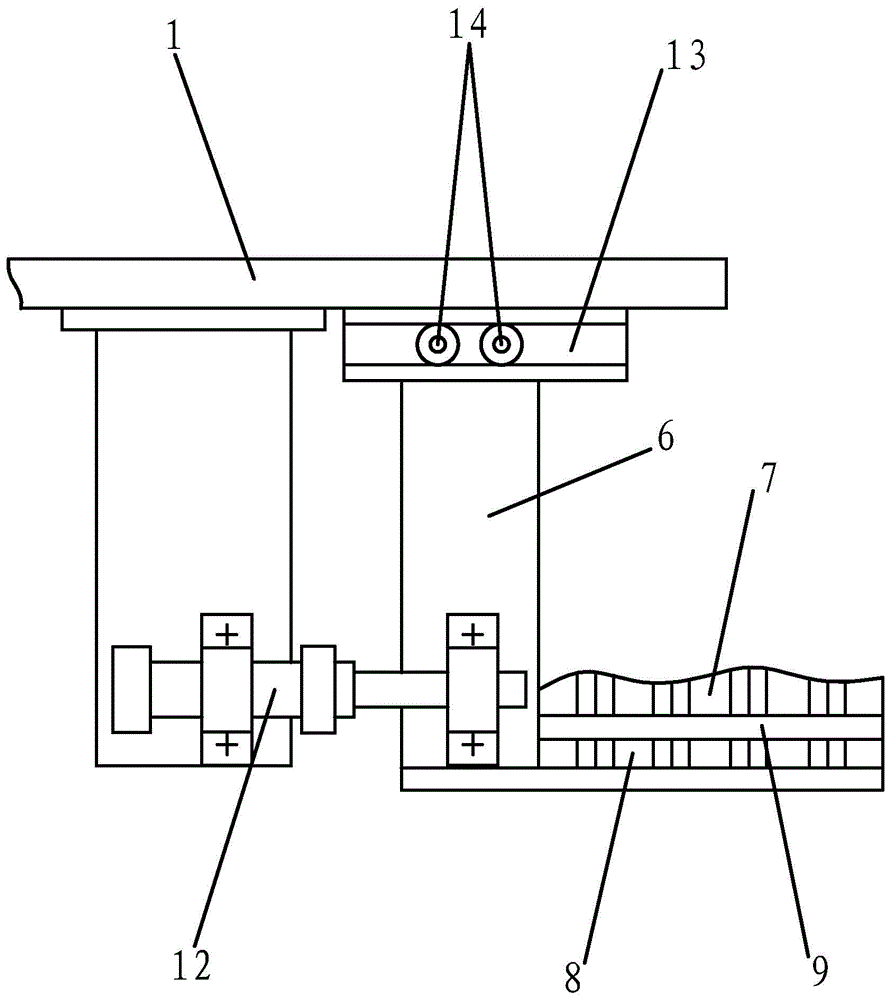

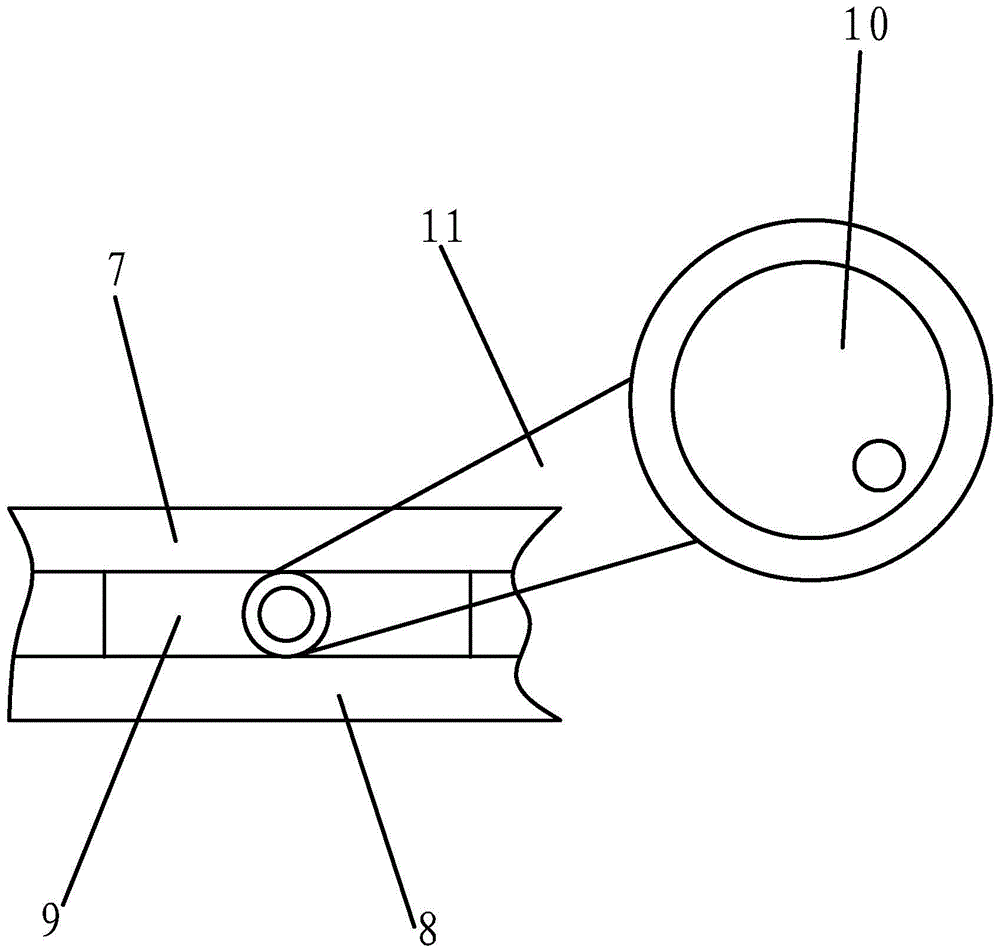

[0038] like figure 1 , figure 2 and image 3 As shown, the intelligent weeding machine includes a mobile trolley, the mobile trolley has a working platform 1, a computer 3 and an integrated controller 4 are arranged on the working platform 1, and cameras 2 are arranged on both sides of the computer 3, and the integrated controller 4 is electrically connected to the computer. 3. With the camera 2, the lower part of the working platform 1 is provided with an inter-row weeding device located on the front side and an in-row weeding device located on the rear side. The inter-row weeding device includes a weeding mechanism, and the in-row weeding device includes two left-right symmetrical weeding mechanisms, An internal and external moving mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com