Induction coil with dynamically variable coil geometry

An induction coil, variable technology, used in induction heating, coil installations, transformer/inductor coils/windings/connections, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

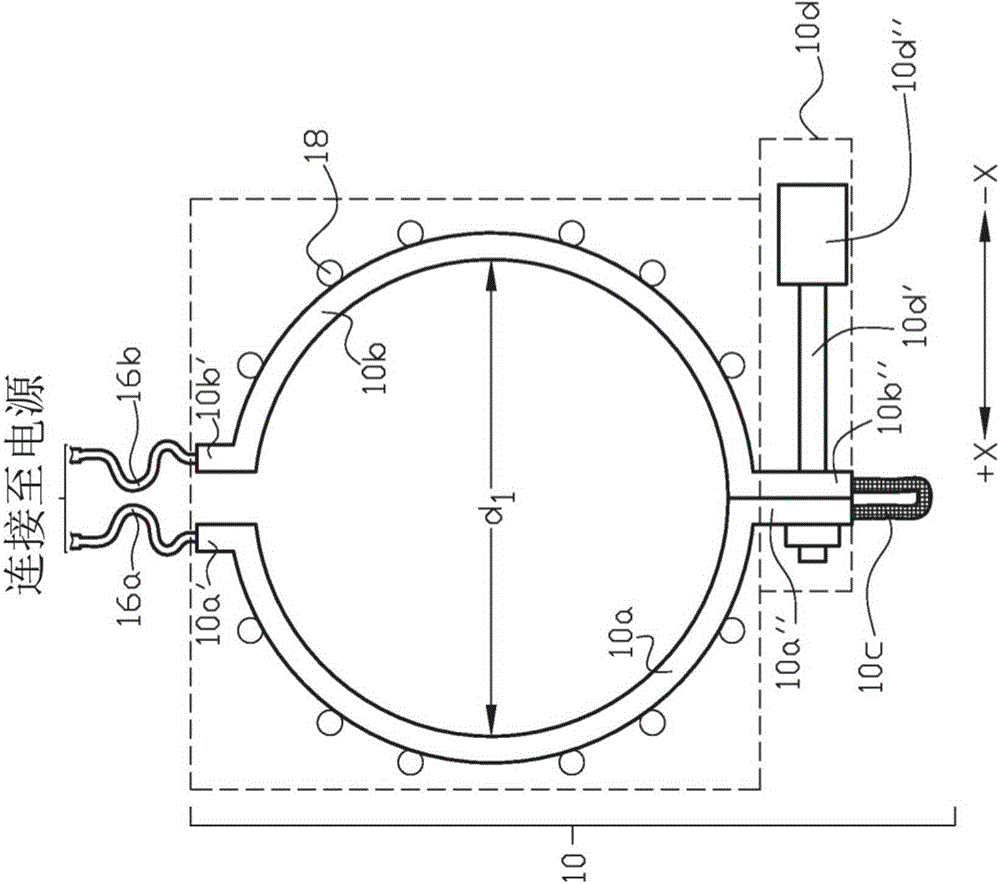

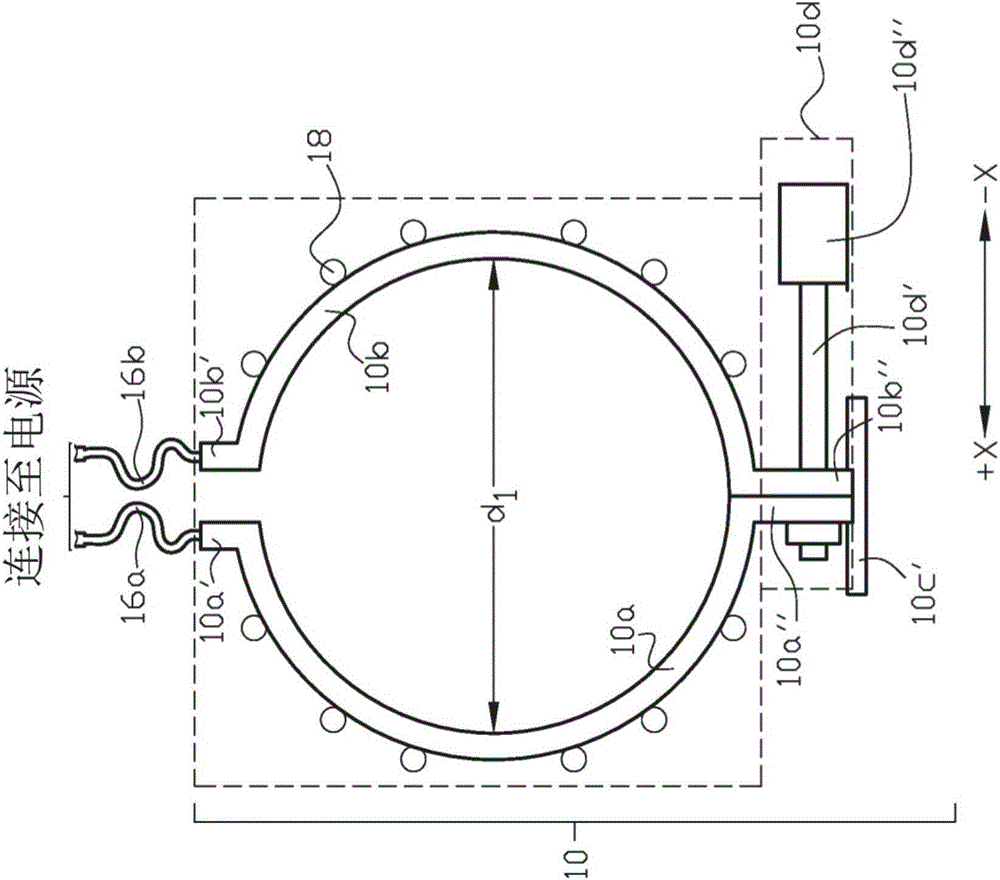

[0017] An example of a solenoid-type induction coil 10 having a dynamically variable coil shape is shown in diagrammatic cross-sectional FIGS. 1( a ) and 1 ( b ). The induction coil 10 is an at least one turn solenoid type coil comprising fixed inductive coil segments 10a and 10b and one or more adjustable coil segments 10c, each of which is combined with a separate adjustable coil segment assembly 10d connect.

[0018] The coil segments 10a and 10b are fixedly fixed along at least part of their coil segment lengths, or connected to the coil segments by elements. For example, as shown in the Figures, the power terminal ends 10a' and 10b' of the coil segments 10a and 10b may be securely secured adjacent to each other with space between the power terminals to provide electrical isolation between the power terminal ends. The space may be filled with an electrically insulating material, such as polytetrafluoroethylene or other suitable material. Optionally, flexible joints may b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com