Crane system

A technology for cranes and heavy objects, which is applied in the directions of travel mechanism, load block, transportation and packaging to achieve the effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

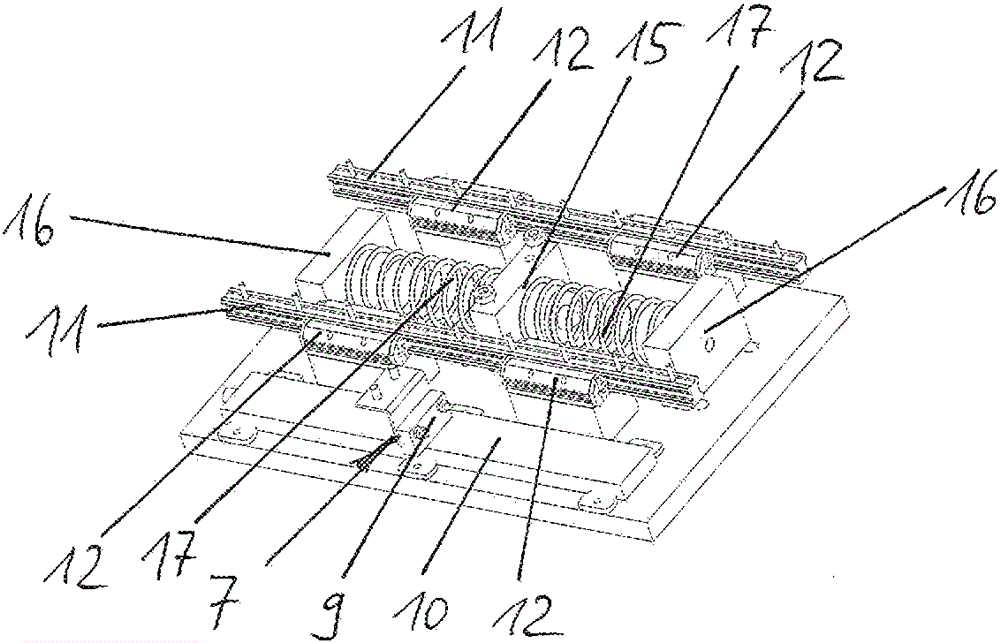

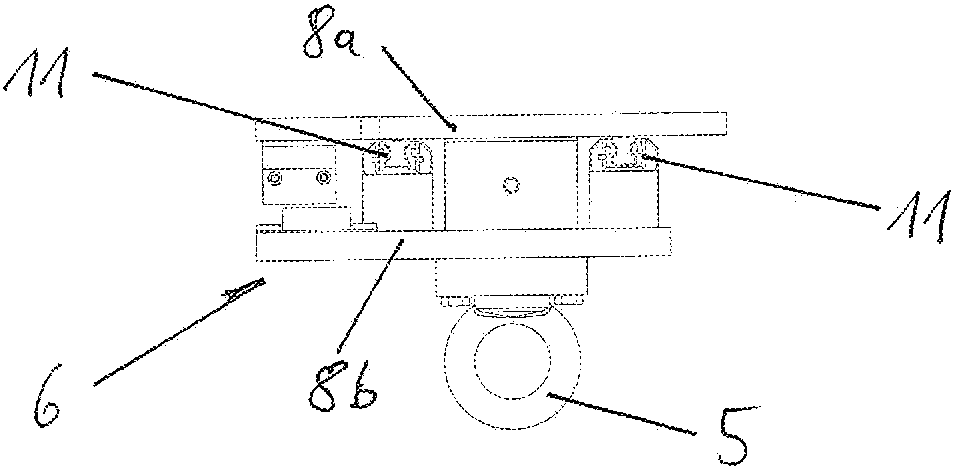

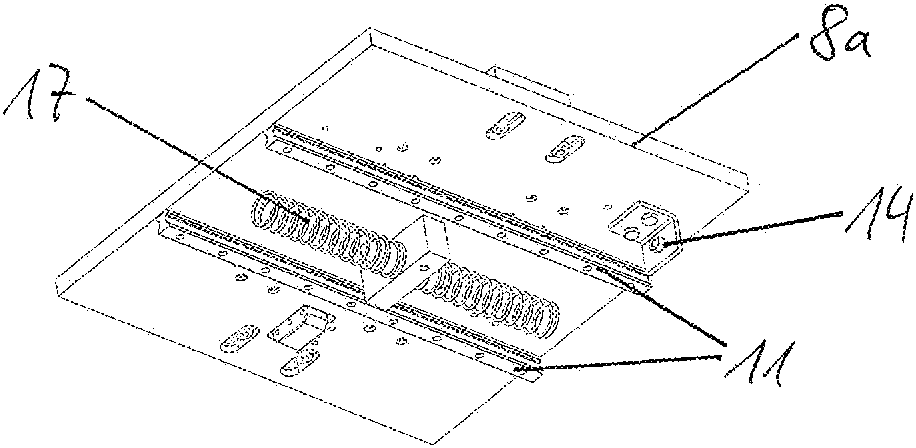

[0043] exist figure 1 shows a crane system for transporting and possibly lifting and lowering loads. The crane system 1 consists at least of a crane longitudinal profile 2 which can be fixed on a frame and a carriage 3 which can be moved along the crane longitudinal profile 2 . A device 5 for receiving and holding a load is arranged on the chassis 3 . The movement of the chassis 3 along the longitudinal crane profile 2 is effected here by means of the drive 4 of the electric motor. According to the invention, a force-receiving and force-transforming unit 6 is arranged between the chassis 3 and the load-receiving device 5 . To control the drive 4 of the electric motor, a force reception and force conversion unit 6 is connected to the drive 4 of the electric motor. The connection takes place here via a cable not shown in the figure. The force reception and force conversion unit 6 has a sensor 7 for detecting mechanical force impulses for the direction of movement, speed and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com