TiO2/CdS/graphene composite photocatalytic material and preparation method therefor

A technology of graphene composite and photocatalytic materials, which is applied in the field of TiO2/CdS/graphene composite photocatalytic materials and its preparation, to achieve the effects of convenient operation, reducing photocorrosion problems and preventing photocorrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

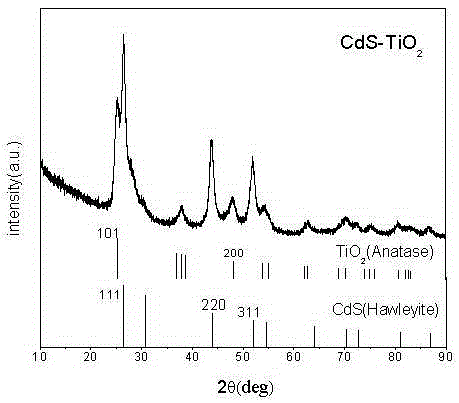

[0029] a TiO 2 / CdS / graphene composite photocatalytic material, made of TiO 2 / CdS composite and graphene oxide composite, calculated by mass ratio, namely TiO 2 / CdS:graphene oxide is 100:5.

[0030] One of the above TiO 2 The preparation method of / CdS / graphene composite photocatalytic material specifically comprises the following steps:

[0031] (1) CdCl 2 2.5H 2 O, Na 2 S·9H 2 Dissolve O in deionized water, and after uniform dispersion, slowly add the sodium sulfide solution to the cadmium chloride solution, react for 2 hours under magnetic stirring, transfer to a 50ml polytetrafluoroethylene-lined stainless steel hydrothermal reactor, and react at 150°C for 12 hours , and then washed three times with deionized water and absolute ethanol and dried at 80 °C to obtain CdS yellow powder.

[0032] CdCl used above 2 2.5H 2 O, Na 2 S·9H 2 Amount of O and water, as CdCl 2 2.5H 2 O:Na 2 S·9H 2 O:H 2 O is the ratio calculation of 2.28g:2.40g:20ml;

[0033] (2) Disso...

Embodiment 2

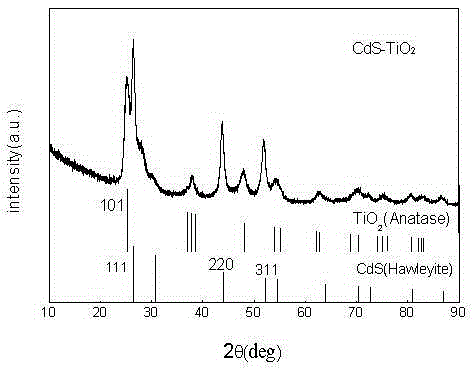

[0043] A kind of TiO 2 / CdS / graphene composite photocatalytic material, made of TiO 2 / CdS composite and graphene oxide composite, calculated by mass ratio, that is, TiO 2 / CdS: graphene oxide is 100:3.

[0044] One of the above TiO 2 The preparation method of / CdS / graphene composite photocatalytic material specifically comprises the following steps:

[0045] (1) CdCl 2 2.5H 2 O, Na 2 S·9H 2 O was respectively dissolved in deionized water, and after uniform dispersion, the sodium sulfide solution was slowly added dropwise to the cadmium chloride solution, reacted for 1.5 hours under magnetic stirring, and transferred to a 50ml polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle for reaction at 150°C 8h, and then washed three times with deionized water and absolute ethanol successively, and then dried at 80°C to obtain a yellow powder of CdS.

[0046] CdCl used above 2 2.5H 2 O, Na 2 S·9H 2 Amount of O and water, as CdCl 2 2.5H 2 O:Na 2 S·9...

Embodiment 3

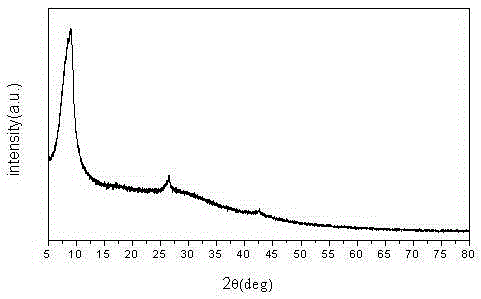

[0057] The CdS yellow powder obtained in step (1) of Example 1 and the TiO obtained in step (2) of Example 1 were 2 / CdS composite, TiO finally obtained in Example 1 2 The / CdS / graphene composite photocatalytic material is used for the degradation of methylene blue, and the steps are as follows:

[0058] Take 3 copies with a concentration of 1.0×10 -4 mol / L aqueous solution of methylene blue, add 30 mg of CdS yellow powder obtained in step (1) of Example 1 and TiO obtained in step (2) of Example 1 respectively 2 / CdS composite, TiO finally obtained in Example 1 2 The / CdS / graphene composite photocatalytic material was subjected to adsorption and desorption equilibrium under the dark reaction for 1 h, and then irradiated under a 500w xenon lamp for 20 min. After photolysis, the degradation rate of methylene blue was measured. As a result, the degradation rate of methylene blue was catalyzed by CdS. 17.4%, TiO 2 / CdS coating catalyzed the reaction, the degradation rate of me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com