Controlled-release fertilizer for lychee and method for preparing controlled-release fertilizer

A technology of controlled-release fertilizer and lychee, which is applied in the field of lychee controlled-release fertilizer and its preparation, can solve the problems of low fertilizer utilization efficiency, decline in the quality of agricultural products, and poor controlled-release effect of fertilizers, so as to avoid fertilizer shortage, increase growth rate, and reduce The effect of causing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

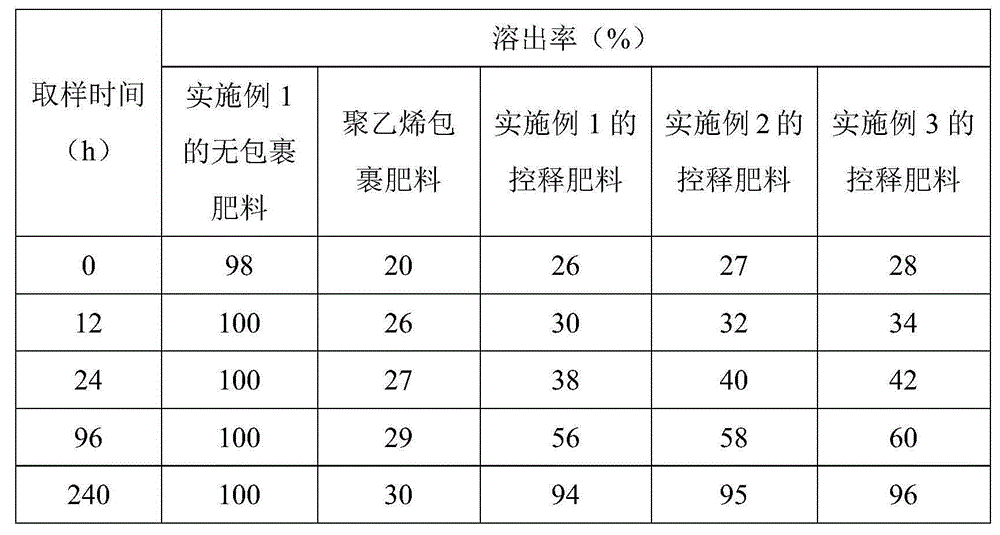

Embodiment 1

[0050] A lychee controlled-release fertilizer, which comprises the following raw materials in parts by weight: 50 parts of wrapping materials and 1600 parts of fertilizer granules;

[0051] The wrapping material is in parts by weight, including the following raw materials: 30 parts of slow-release agent, 20 parts of binder, and the slow-release agent is in parts by weight, including the following raw materials: 8 parts of talcum powder, 8 parts of gypsum powder , 4 parts of diatomite, 4 parts of bentonite, 4 parts of peat, 1 part of ammonium dihydrogen phosphate powder, and 1 part of potassium nitrate powder. The binder includes the following raw materials in parts by weight: 16 parts of starch, three parts Potassium phosphate 3 parts, calcium hypochlorite 0.5 part, furfural 0.5 part;

[0052] The fertilizer granules are in parts by weight and include the following raw materials:

[0053] 310 parts of leafless horsetail, 310 parts of paulownia leaves, 190 parts of poison ivy,...

Embodiment 2

[0059] A lychee controlled-release fertilizer, which comprises the following raw materials in parts by weight: 150 parts of wrapping materials and 200 parts of fertilizer granules;

[0060] The wrapping material is in parts by weight, including the following raw materials: 80 parts of slow-release agent, 70 parts of binder, and the slow-release agent is in parts by weight, including the following raw materials: 25 parts of talcum powder, 20 parts of gypsum powder , 10 parts of diatomite, 10 parts of bentonite, 10 parts of peat, 3 parts of ammonium dihydrogen phosphate powder, and 2 parts of potassium nitrate powder. The binder includes the following raw materials in parts by weight: 55 parts of starch, pyrophosphoric acid 8 parts of potassium, 4 parts of sodium hypochlorite, 3 parts of glyoxal;

[0061] The fertilizer granules are in parts by weight and include the following raw materials:

[0062] 30 parts of leafless horsetail, 30 parts of paulownia leaves, 25 parts of pois...

Embodiment 3

[0068] A lychee controlled-release fertilizer, in parts by weight, comprising the following raw materials: 100 parts of wrapping material, 900 parts of fertilizer granules;

[0069] The wrapping material is in parts by weight, including the following raw materials: 55 parts of slow-release agent, 45 parts of binder, and the slow-release agent is in parts by weight, including the following raw materials: 16 parts of talcum powder, 14 parts of gypsum powder , 7 parts of diatomite, 7 parts of bentonite, 7 parts of peat, 2 parts of ammonium dihydrogen phosphate powder, 2 parts of potassium nitrate powder. 3 parts of potassium, 2 parts of dipotassium hydrogen phosphate, 1 part of potassium hypochlorite, 1 part of sodium perchlorate, 1 part of glutaraldehyde, 1 part of water-soluble silane;

[0070] The fertilizer granules are in parts by weight and include the following raw materials:

[0071] 180 parts of leafless horsetail, 180 parts of paulownia leaves, 105 parts of poison ivy,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com