Segmented bundling equipment for strip-shaped soft materials

A soft material and strip-shaped technology, which is applied in the direction of bundling materials, parts of bundling machinery, paper/cardboard containers, etc., can solve problems such as limited production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

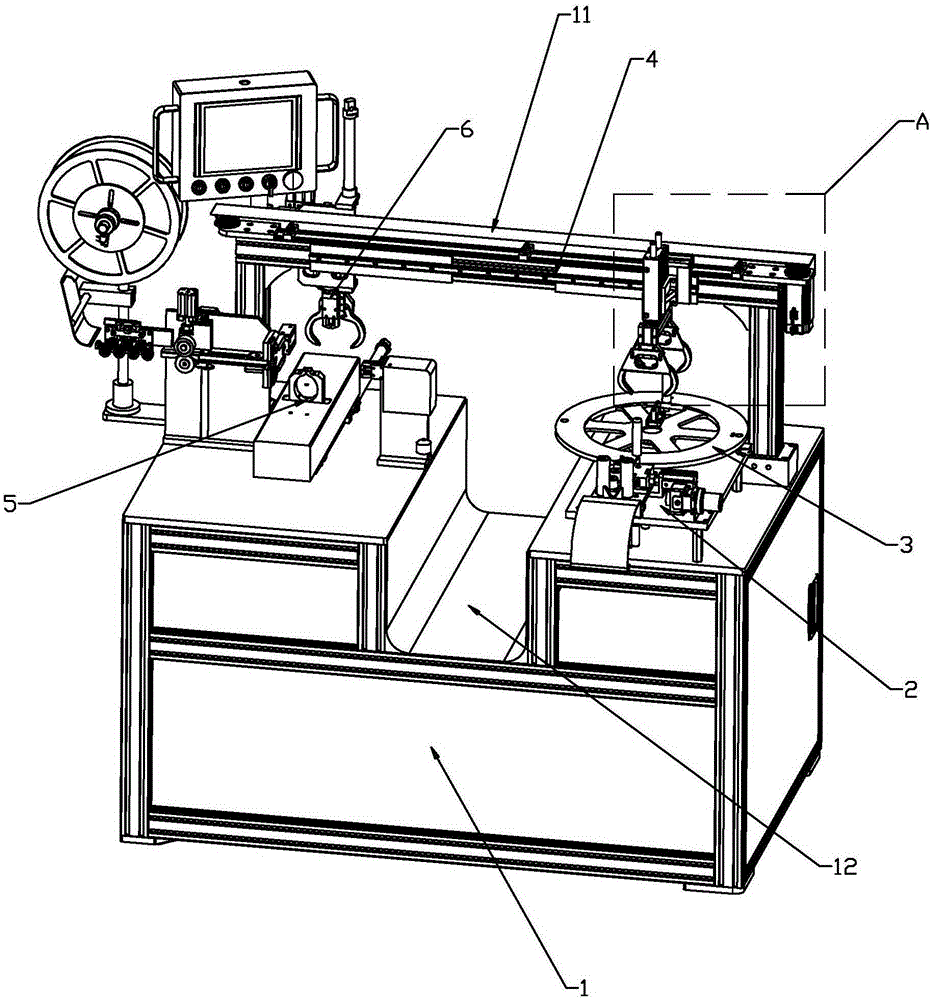

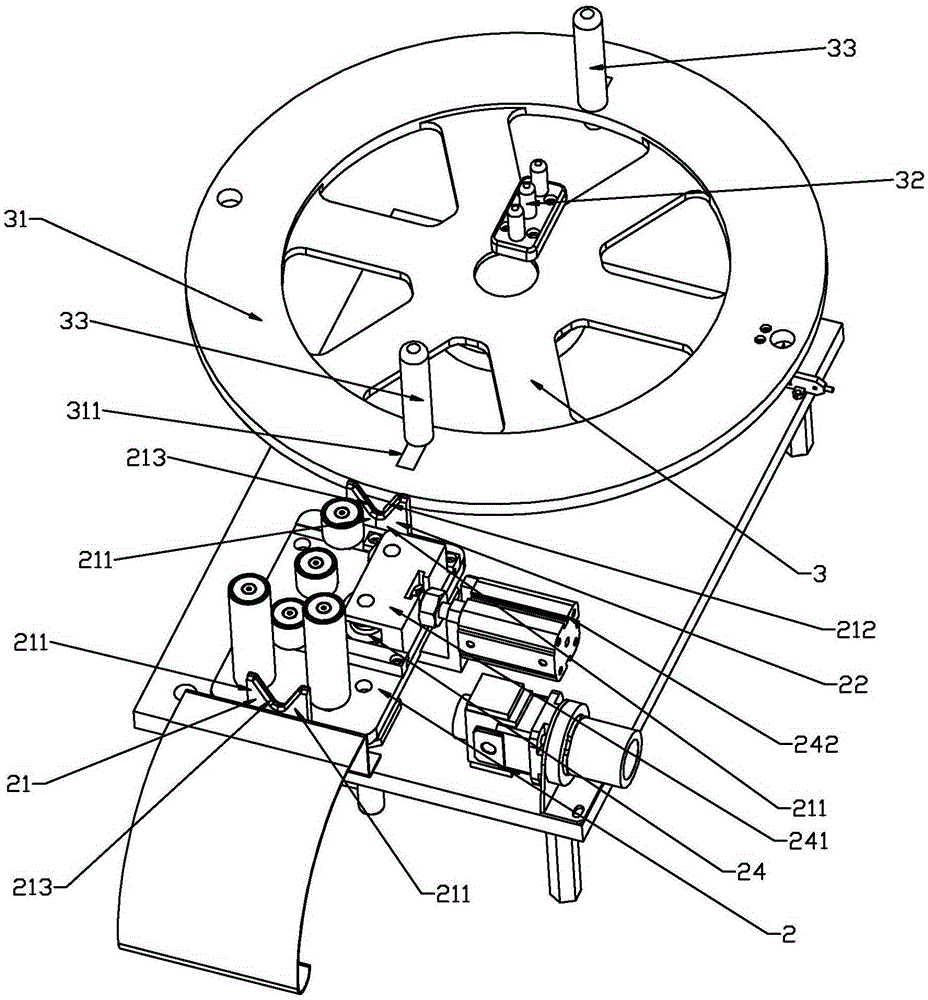

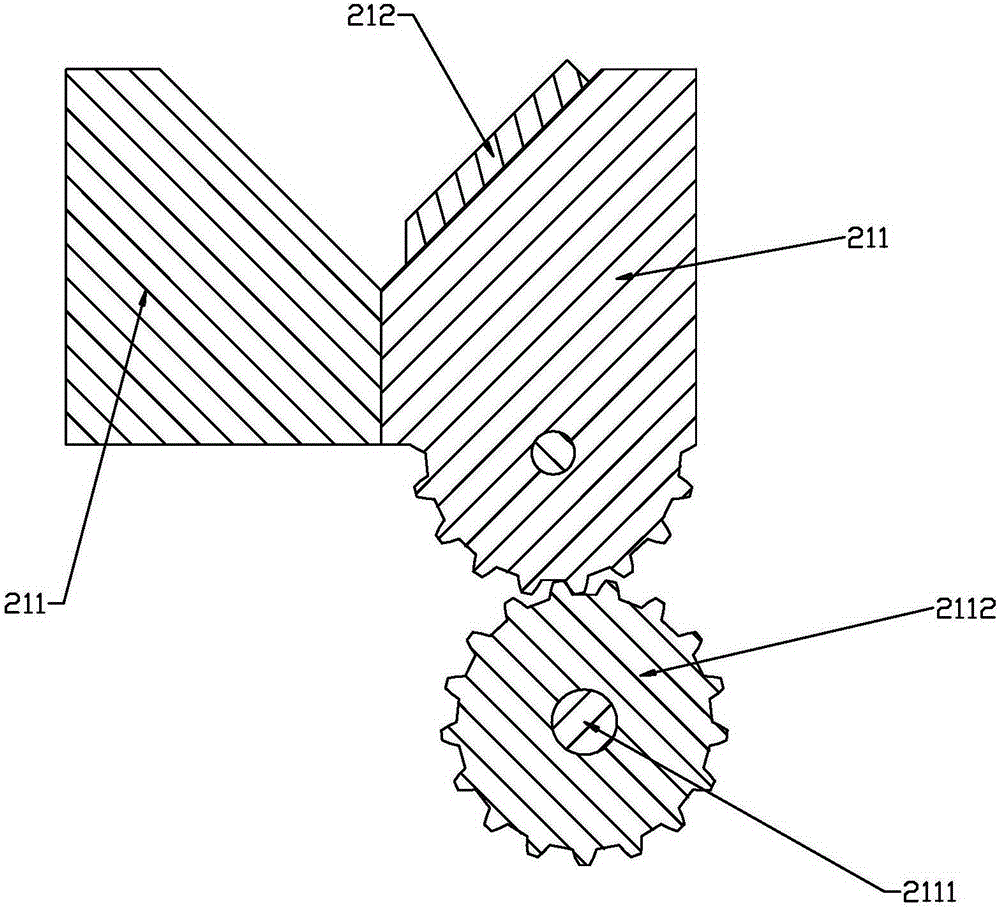

[0034] Such as figure 1 — Figure 10 As shown, the present invention discloses a segmented binding equipment for strip-shaped soft materials, including a workbench 1, on which a feeding device 2 for segmenting and pushing the strip-shaped soft materials, The rolling device 3 that rolls the strip-shaped soft material pushed out, the transport device 4 that transfers the rolled strip-shaped soft material to the next station, and the strip-shaped soft material transported by the transport device 4 A binding device 5 for binding soft materials and a discharge device 6 for storing the bundled strip-shaped soft materials. The feeding device 2 includes a front positioning clip 21, an extrusion assembly and a rear positioning clip 22 arranged in sequence along the conveying direction. , the front positioning clip 21 and the rear positioning clip 22 are composed of two triangular positioning units 211, and the middle parts of the two positioning units 211 form a V-shaped groove 213 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com