Strapping machine for soft material in strips with fast handling

A soft material and strapping machine technology, which is applied to the parts of strapping machinery, winding strips, strapping materials, etc., can solve the problems of slow handling of large-scale handling equipment, inconvenient use of strapping equipment, and large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

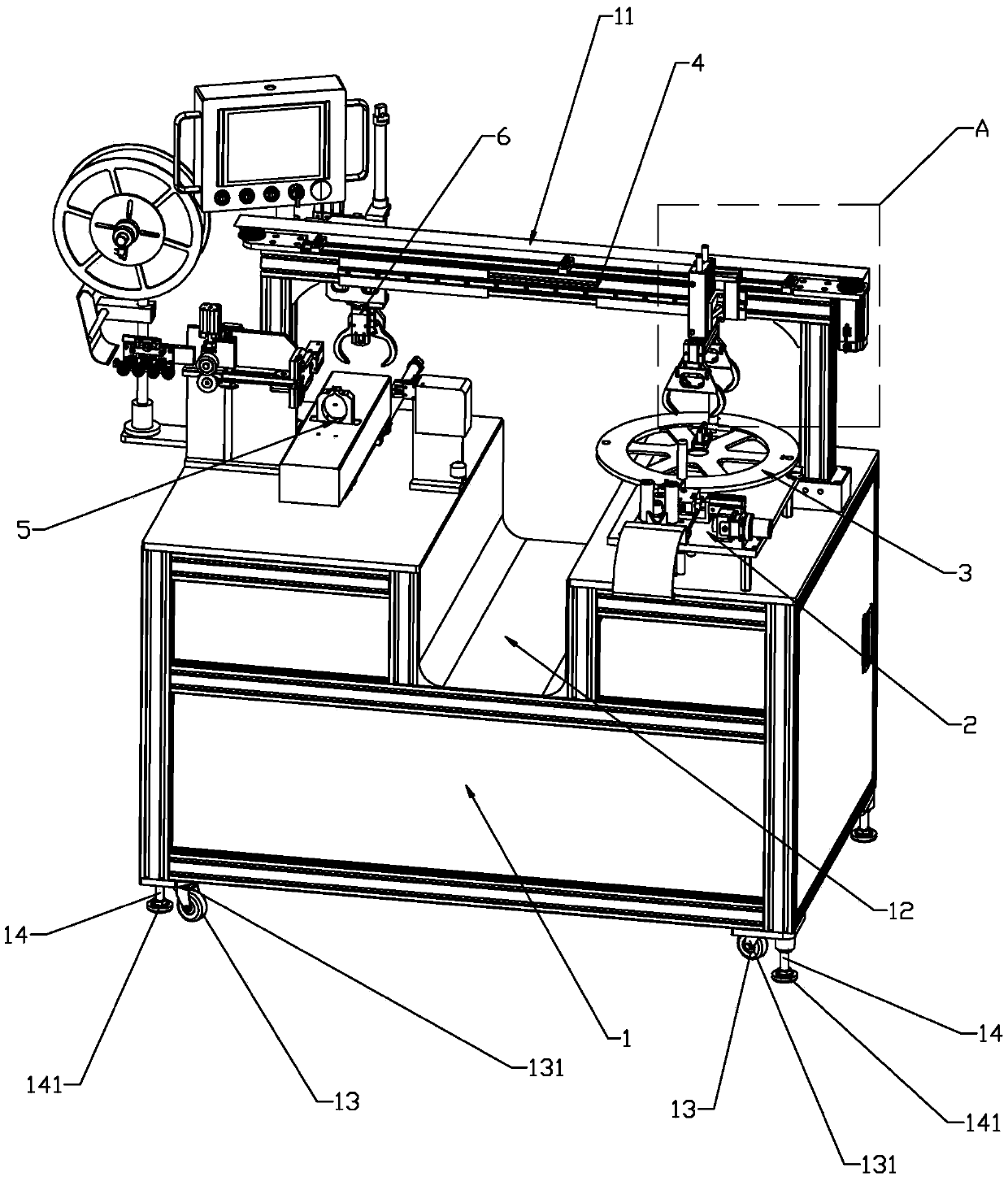

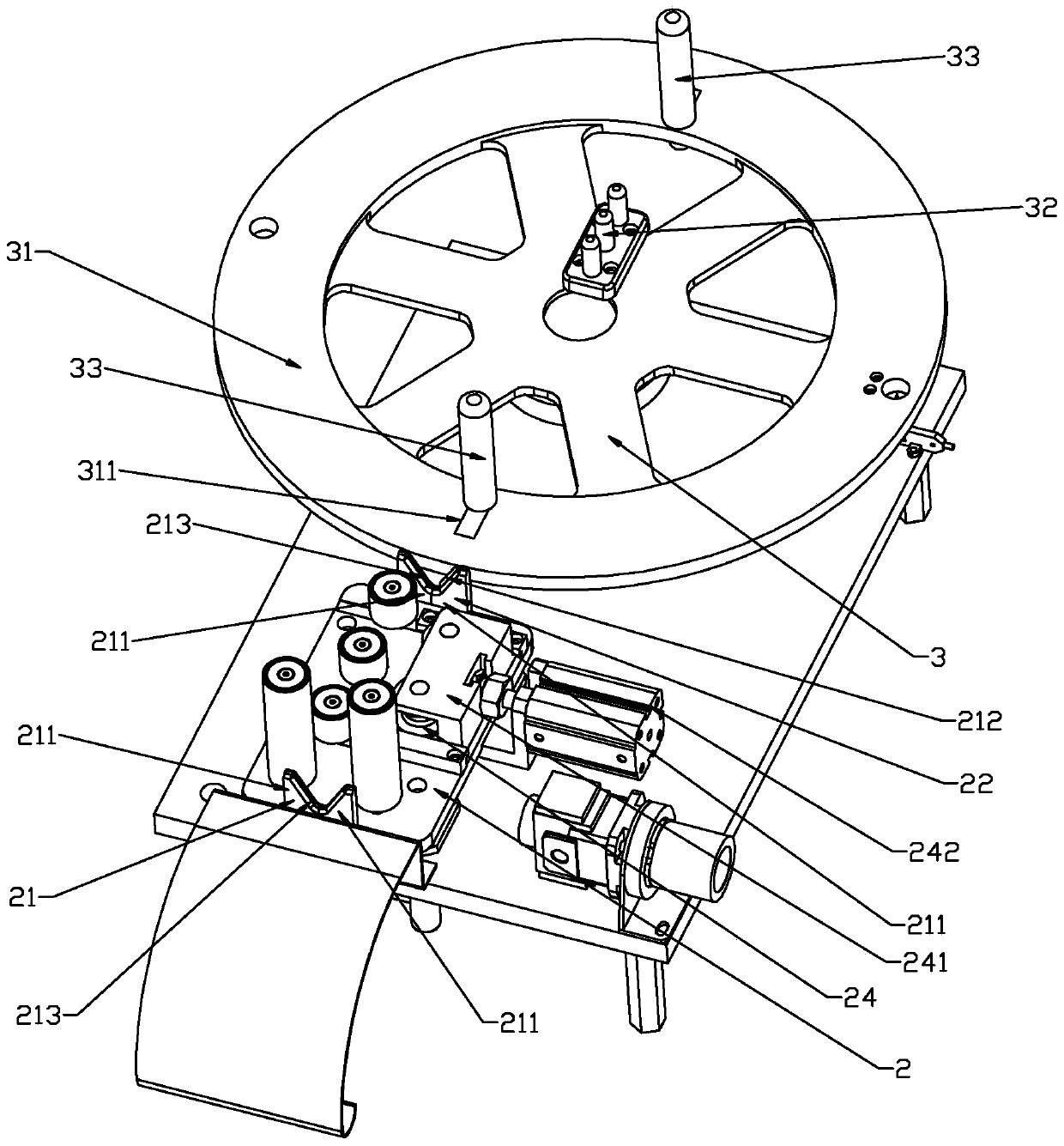

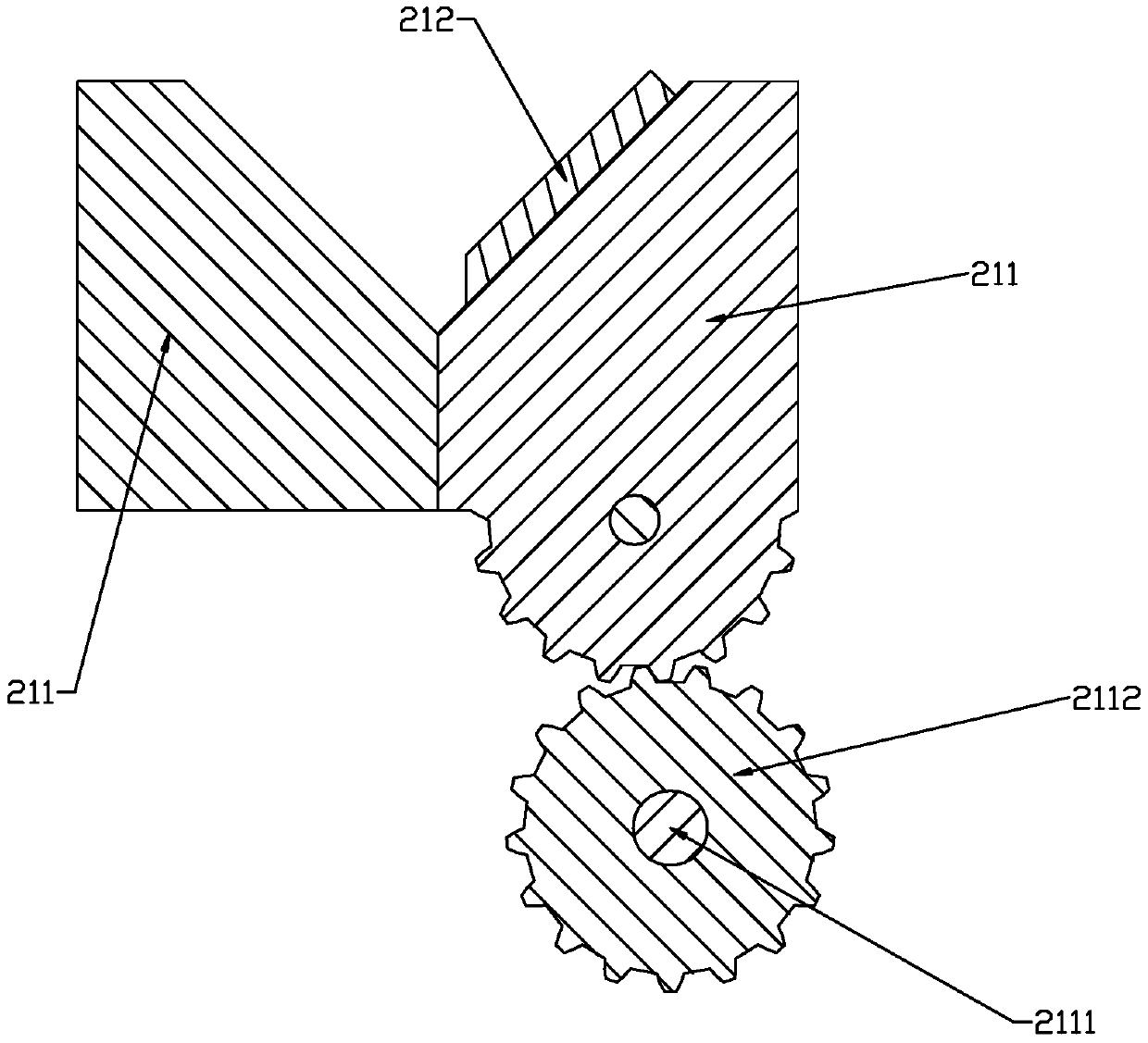

[0034] Such as figure 1 — Figure 10 As shown, the present invention discloses a strip-shaped soft material binding machine with a fast-moving function, which includes a workbench 1 on which a feeding device 2 for segmenting and pushing strip-shaped soft materials is arranged , the rolling device 3 that rolls the strip-shaped soft material that is pushed in sections, the transport device 4 that transfers the rolled strip-shaped soft material to the next station, and transports the transport device 4 A strapping device 5 for bundling the strip-shaped soft materials and a discharge device 6 for storing the bundled strip-shaped soft materials. The feeding device 2 includes a front positioning clamp 21, an extruding assembly and Rear positioning clip 22, front positioning clip 21 and rear positioning clip 22 are made up of two triangular positioning units 211, and the middle part of two positioning units 211 forms a V-shaped groove 213 for placing strip-shaped soft materials. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com