Multi-lens camera module one-piece bracket, multi-lens camera module and application of multi-lens camera module

A camera module and multi-lens technology, applied in the fields of photo filters, image communication, instruments, etc., can solve the problems of deformation, size, position difficult to control, poor consistency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below with reference to the accompanying drawings and embodiments, so that anyone skilled in the art can make and use the present invention. The embodiments in the following description are by way of example only and modifications will be apparent to those skilled in the art. The general principles defined in the following description will apply to other embodiments, alternatives, modifications, equivalent implementations and applications without departing from the spirit and scope of the invention.

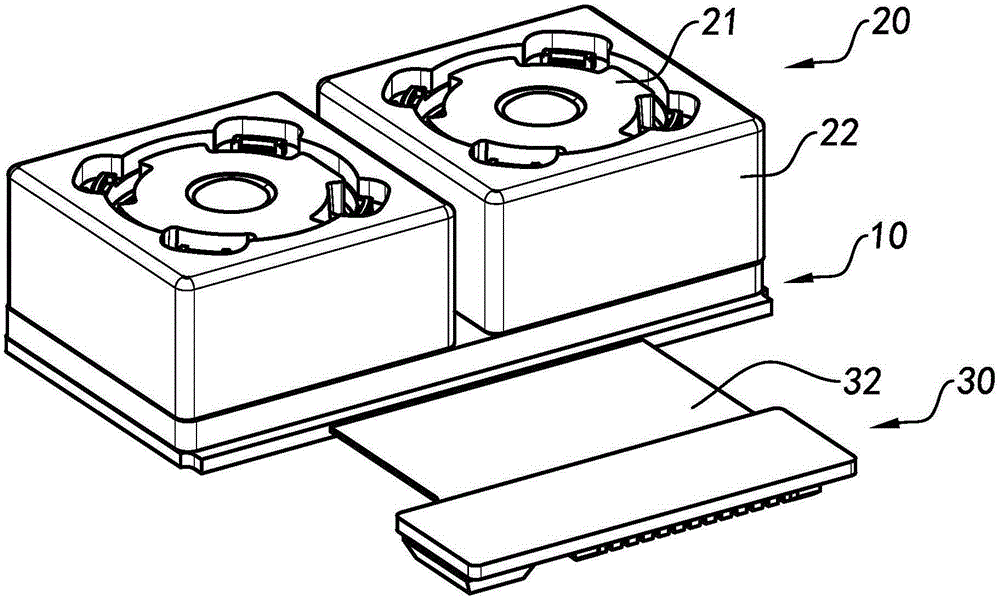

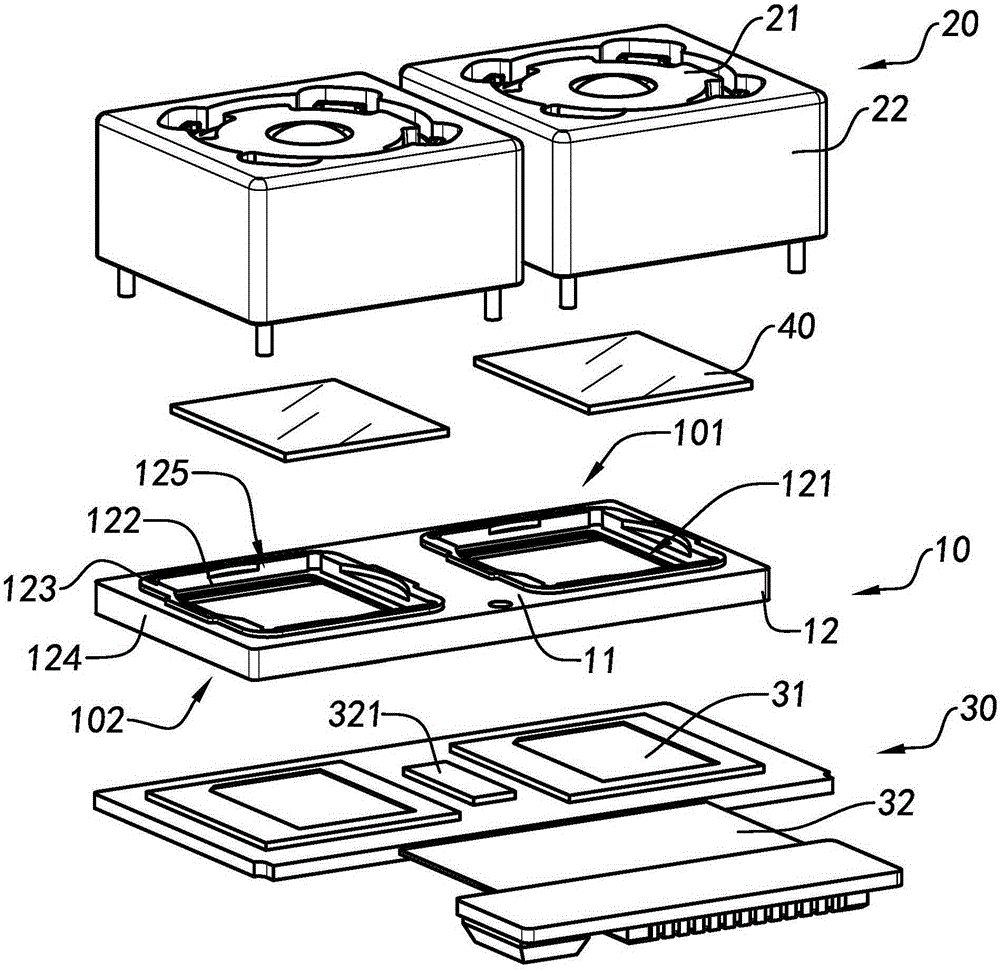

[0061] Such as Figure 2 to Figure 5B Shown is a multi-lens camera module according to a preferred embodiment of the present invention, the multi-lens camera module can be applied to various electronic devices to assist users to take pictures of objects or For images of people, for example, the multi-lens camera module can be used to capture images or videos of objects or people. Preferably, the multi-lens camera module can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com