Live suspension clamp fastening device

A technology of suspension wires and clamps, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as looseness, nut 6 falling off and missing, hidden safety hazards, etc., and achieve the effect of reasonable structure and convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

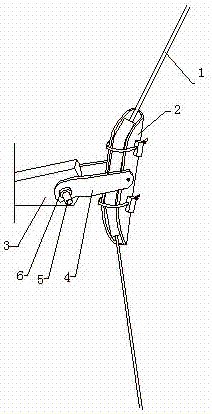

[0017] as attached figure 1 As shown, when the nut 6 needs to be reinstalled after being loose or lost, it is first necessary to clamp the connecting splint 4 on both sides of the suspension clamp 2, and then fix the bolt 5 so that the nut 6 can be firmly tightened on the bolt 5 Above, for this operation step, the following fastening device is provided in this embodiment.

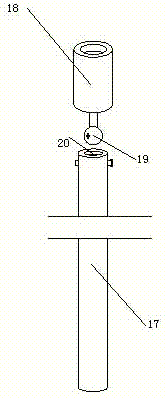

[0018] The fastening device provided in this embodiment includes an attached figure 2 Nutrunner shown with attached image 3 The holder is shown in two parts.

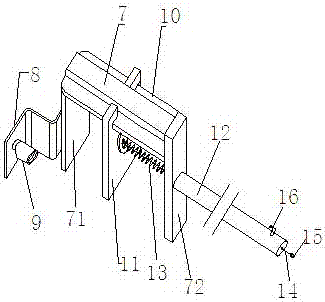

[0019] as attached image 3 As shown, the clamper provided in this embodiment includes an inverted U-shaped clamping frame 7, and an L-shaped bolt positioning plate 8 extending outward is arranged on the front end frame plate 71 of the clamping frame. A bolt sleeve 9 is provided.

[0020] as attached image 3 As shown, slideways 10 are respectively provided on the left and right sides of the back of the clamping frame, and a movable push plat...

Embodiment 2

[0028] The structure of the nut tightener provided in this embodiment is the same as that in Embodiment 1, and only the structure of the holder is further improved.

[0029] Since the clamping force of the movable push plate 11 and the front end frame plate 71 of the clamping frame to the connecting splint 4 on both sides of the suspension clamp 2 in Embodiment 1 only relies on the elastic force of the support spring 13 to clamp, the elastic force is limited, and sometimes it is difficult to fix the suspension. The connecting splints 4 on both sides of the wire clip 2 are clamped and closed, which leads to the need to rely on the tightening force of the nuts to clamp the connecting splints 4 when installing the nuts, making it difficult to install the nuts. In order to solve this problem, this embodiment further improves the holder.

[0030] as attached Figure 4 As shown, the structure of the clamping frame in the clamp provided in this embodiment is consistent with the stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com