Helix Dynamic Measuring Method and Measuring Device

A technology of dynamic measurement and measuring devices, applied in the direction of measuring devices, electrical devices, instruments, etc., can solve the problems of high technical requirements for operators, difficult maintenance and low measurement efficiency, etc., and achieve low environmental requirements and simple structure , Improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

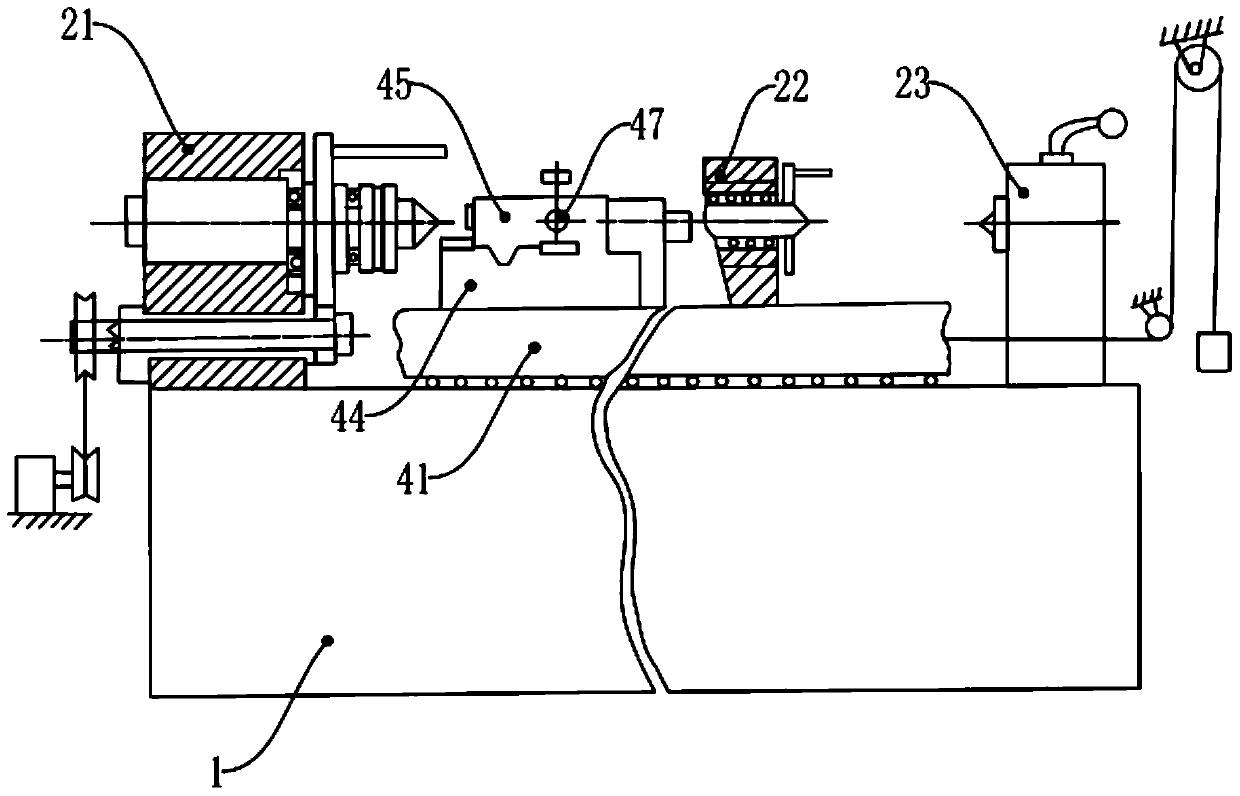

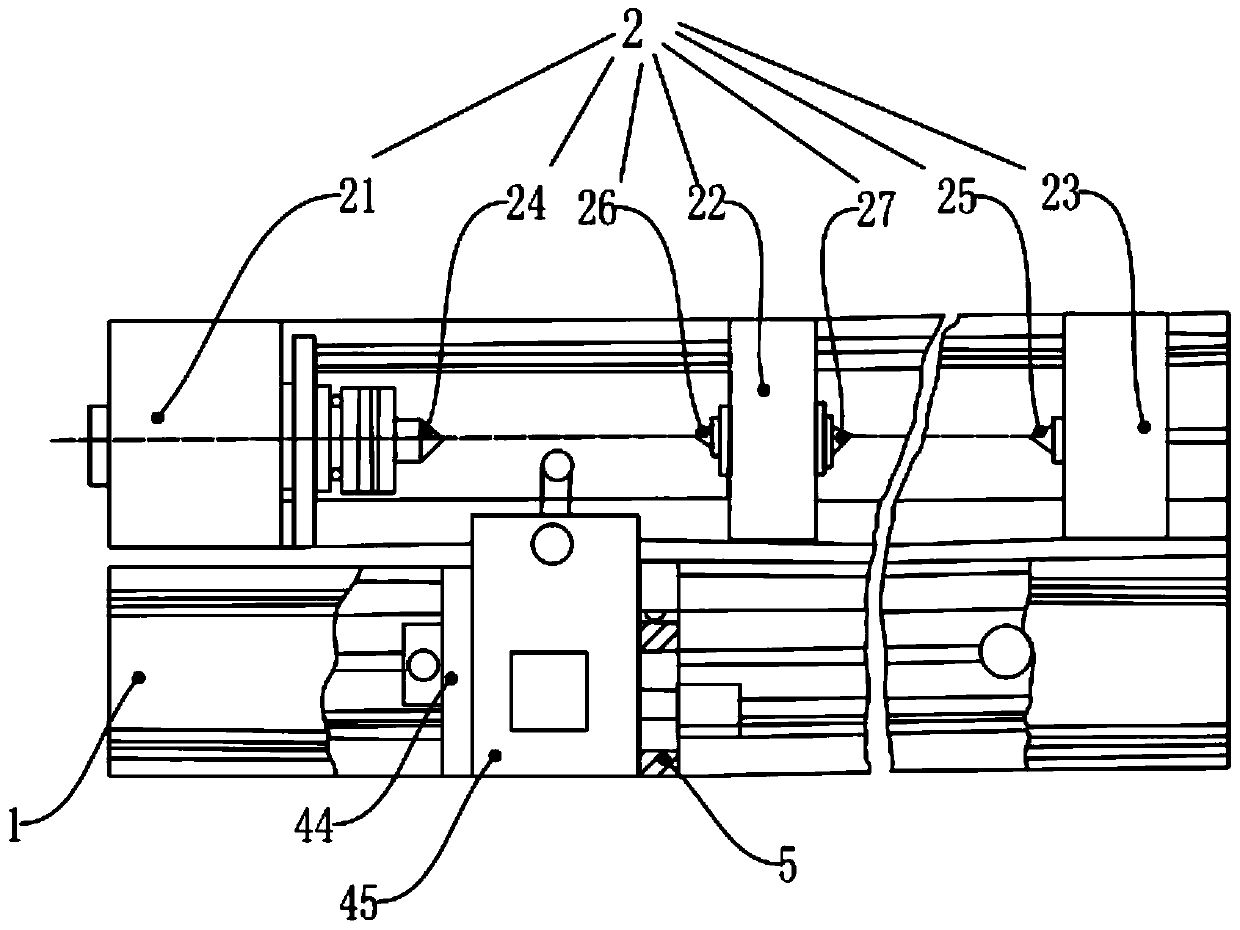

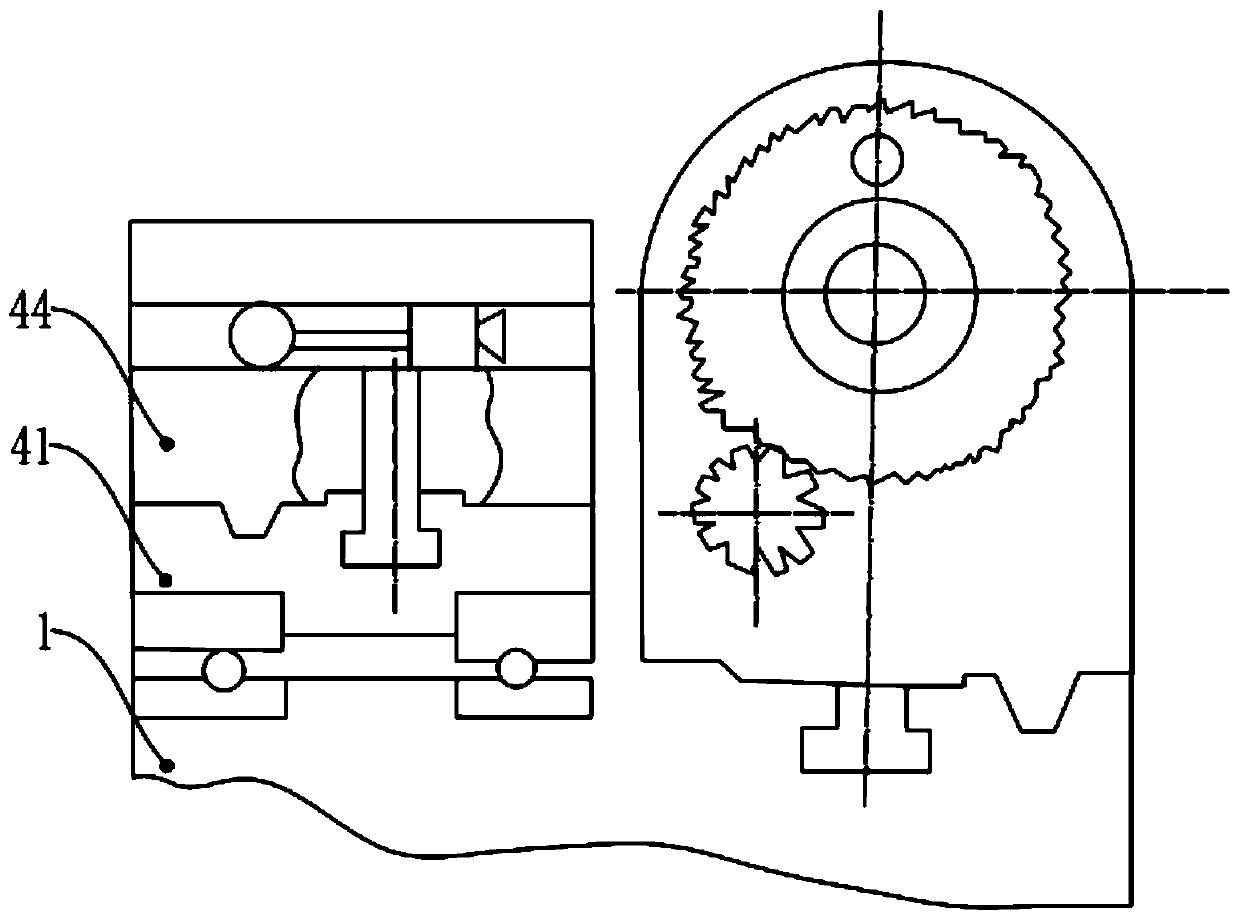

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0028] It should be noted here that the accompanying drawings are only schematic diagrams used to illustrate this solution, and are not drawn strictly to scale. Except for explicit descriptions, they are only used to facilitate the understanding of the solution and do not constitute a substantial limitation to the solution.

[0029] Such as Figure 1 to Figure 8 Shown, the helix dynamic measurement method, it comprises the following steps:

[0030] 1), the measurement of the helix of the reference screw mandrel 100, the computer records the error curve f(x) of the reference screw mandrel 100 基 ;

[0031] 2), the measurement of the helix of the tested screw mandrel 101 is based on the reference screw mandrel 100 in step 1), and the measured screw mandrel 101 and the reference screw mandrel 100 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com